Table of Contents

Product packaging can be seen as an essential factor in presenting your products professionally while adding value to the customer’s experience with your brand.

Your product’s packaging will have a huge influence on a customer’s purchasing decision, so it should never go unnoticed.

Now that you have a better understanding of what your packaging costs will look like, you can start making plans to reduce these costs to fit into your budget.

Cutting on costs doesn’t necessarily mean cutting on quality.

There are plenty of cost effective ways to create high quality packaging that enhances your brand narrative and serves your customers.

Whether you are a luxury brand or a restaurant service, custom packaging, at any cost, will gain you brand exposure and in turn boost your sales!

Creating trendy and shareable packaging has now become a focal point in advertising and marketing strategies.

Organizations are integrating unique and creative packaging into impactful digital marketing campaigns to increase brand recognition and exposure exponentially.

Finding the right balance between communicating your brand through packaging and managing your budget can be difficult.

Here we lay out the top considerations for achieving that perfect balance!

Saving on Materials and Structures

When looking for packaging, finding the optimal material and structure of your custom boxes is essential to your product’s success.

Not only will it boost your product presentation, but you’ll be able to optimize your brand identity through your packaging!

You may be thinking that purchasing the top quality material is the best bet to ensure your product will make it through the shipping process and to your customer safely.

The reality is; opting for the highest quality materials can be quite costly when they simply don’t need to be.

Keeping packaging costs low means being mindful of all the core choices you make for your custom packaging project.

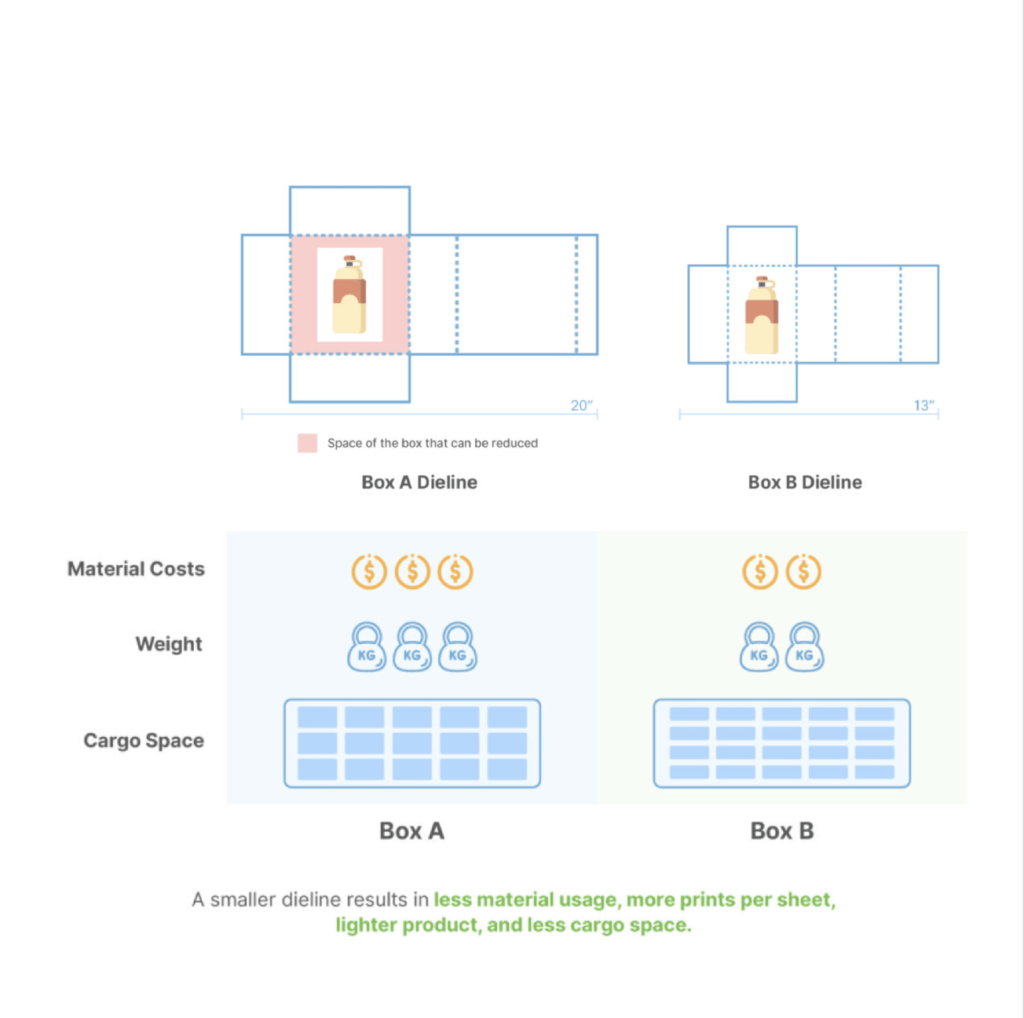

Minimizing your packaging dimensions to be tailored to the smallest size your product needs will actually save on your costs and be much safer for your products too.

Here are some examples of materials and structures that you should seek when creating cost effective packaging for your products.

Corrugated Fibre Board

Opting for cheaper materials for your products doesn’t always mean sacrificing the quality of your brand.

One of the most cost-effective materials to seek out when producing cost efficient boxes is corrugated fibreboard.

Corrugated fiberboard consists of fluted corrugated sheets sandwiched between strong paperboards for optimal durability.

This material offers a stable cushioning for any product that requires extra support and protection during long-distance shipping and handling.

Depending on how fragile or heavy your items are, corrugated material can be customized with regards to size and thickness to ensure your products are well accommodated.

On top of being an inexpensive material to purchase, corrugated fibre board is also easy to manipulate and assemble into your desired shape.

This is beneficial because it reduces the required labour needed to tailor your packaging to your products, thus reducing not only your time, but your costs too!

Opting for standardized structures will help keep your costs for corrugated packaging much lower than customizing unique shapes.

Some popular standardized structures include;

Sticking with standardized structures doesn’t mean that your packaging can’t be unique though.

You can opt for different sizes, artwork designs and finishes that will set your brand apart from the competition.

Corrugated packaging offers a variety of branding opportunities through printing and finishing for a budget friendly solution.

Read more on corrugated packaging.

Folding Carton

Folding Carton is another excellent choice when looking for materials to build cost-effective boxes.

Want to opt for premium packaging but just don’t have the budget for it?

Folding Carton is your answer!

This material is available in a variety of paperboard options and has the capability to offer the highest quality printing and finishing options to achieve the same feel as the premium packaging you are longing for.

This affordable box option is ubiquitous with packaging as a whole.

How ubiquitous?

Well, The cereal you enjoyed this morning came in a folding carton box.

Folding cartons open doors of opportunity for your products and brand, without breaking your bank account and is extremely popular across a range of industries.

Kraft folding cartons are made from recycled materials, are 100% recyclable and are sure to get recognition from your eco-friendly shoppers.

Thanks to Folding carton’s wide availability, its manufacturing costs are incredibly low for high quality results

Folding cartons are designed to be a flexible material, making it attainable to opt for more unique shapes and sizes that are not conventionally used on the market.

However, it is important to note that structural engineering services may be required to bring your unique shapes to life, making it more expensive to obtain.

This is because new structures should be tested for efficiency before they can be used on the market. Costing you more money and time.

As mentioned previously, opting for standardized structures allows you to keep your packaging costs lower and your products safer.

This is true for packaging as a whole because less room for movement means less room for damage.

Some popular standardized structures for folding carton include;

Again, standardized structures still offer the opportunity to stand out.

With Folding cartons’ versatility in printing and finishing capabilities, you can create a box that emulates luxury and class while still maintaining a smaller budget.

Read more on folding carton packaging

Paper/Plastic Gusset Bags

If you are shipping edible products or products that need a little extra protection within your packaging, gusset bags are probably already on your radar.

Gusset bags are invaluable for product protection especially in the food packaging industry.

These bags ensure your product doesn’t move around during shipping and can also provide another opportunity to add some more branded imagery to your packaging.

You can find gusset bags in both paper and plastic varieties, both of which are inexpensive and valuable to building a brand narrative.

Consumers like easy access and functionality, and gusset bags offer exactly that.

Packaging your items in a bag automatically makes your product more user friendly from a customer perspective.

They can purchase your product, and have it the moment they step out of the store or leave their mailrooms without the hassle of opening an entire box.

Additional Packaging Materials

There is no reason you can’t add customizations to already affordable packaging.

Opting for small personal touches may be especially beneficial for small businesses who can’t afford to opt for extravagant custom packaging or are already satisfied with stock packaging for their products.

Here are some small custom touches you can add to any packaging for a unique and personalized feel.

Tissue Paper and Paper Inserts

If you are shipping a larger or more breakable product, tissue paper and paper inserts are an excellent alternative to adding padding within your packaging for an affordable price.

This is especially effective for boxes containing more than one product.

You’re able to add padding between the products and/or display them in an appealing way to enhance your unboxing experience.

There are a few insert options to consider including;

Paperboard and Plastic Tray inserts are the most cost effective on this list.

Paperboard trays are very effective in offering your products extra support and protection and are great for displaying items such as cosmetics, candles and much more.

Plastic Tray inserts are effective in keeping your products separated within one vessel and are especially great for things like cookies, and baked goods.

Read more about why box inserts are beneficial for your packaging

Custom Sleeves

Custom sleeves look like a costly option that many businesses believe is out of their price range.

However, this is not the case.

They are a great, affordable addition to your packaging, that may just give your product the boost it needs.

The benefit to custom sleeves goes beyond the added marketing and brand exposure. It also adds a layer of functionality to your packaging through offering your product extra sealing capabilities.

Custom sleeves on any packaging communicates that your brand pays attention to detail, which is what consumers thrive for; an authentic connection.

This addition to your cost-effective boxes, whether they are custom or generic, will give it an air of luxury and leave your customer feeling like they just got a steal on a high end product.

Stickers and Labels

Your packaging acts as a spokesperson for your brand and product. However, sometimes custom printing for each box is just out of your budget.

Stickers and labels are one of the simplest ways to add that extra bit of character and shameless brand promotion to your packaging at a very small cost.

Stickers and labels are also a great way to communicate directly with your customers.

Whether it’s a simple ‘thank you’, product instructions or more information on your brand, your customers will feel that your business is attempting to make an authentic connection with them.

Your company branding should be everywhere. So, if you are opting for plain packaging to budget your costs, stickers and labels may be the answer to your branding strategy.

Luckily, the more stickers you buy, the cheaper they become, making them a prime choice for those looking to save on costs and maximize on branding.

Cost Effective Volume Planning

Volume planning involves details such as the order quantity, your product launch plan (your timeline), and setup costs.

The project details and the decisions made for your product packaging are vital to determining the price range.

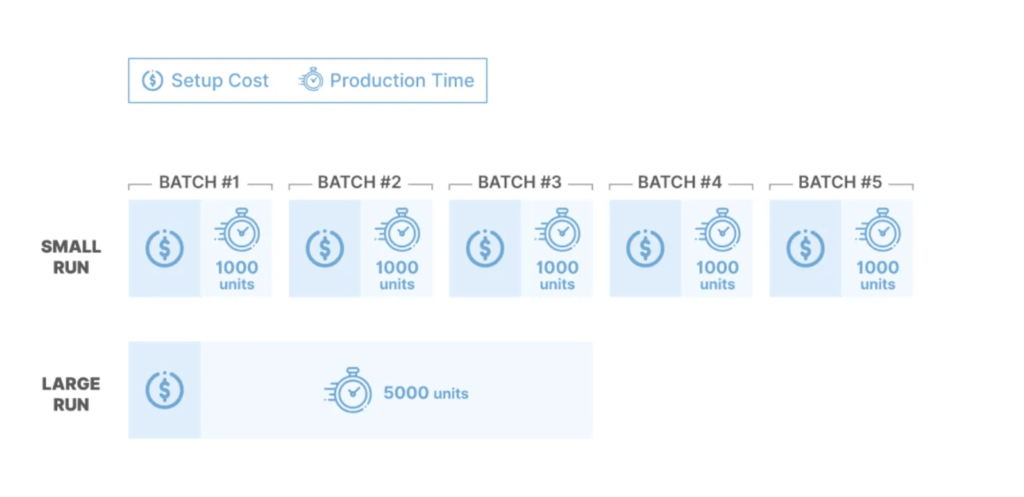

Have you ever noticed that small run projects have a higher unit price than large run projects?

Why is that?

Well, something to remember is that part of the pricing also includes the setup costs.

The setup cost is required to prepare the machine for the production of your boxes based on your project specifications.

This involves cleaning the machine and tooling, changing different components of the machine needed for cutting, dyes, etc.

Small runs will cost more per unit because manufacturers will need to set up the machine for your specifications every time you order a new batch.

Meanwhile, large run projects can produce a large number of units at one time, only needing to set up the packaging machine once.

To summarize you’ll be saving costs for larger run projects, so go big!

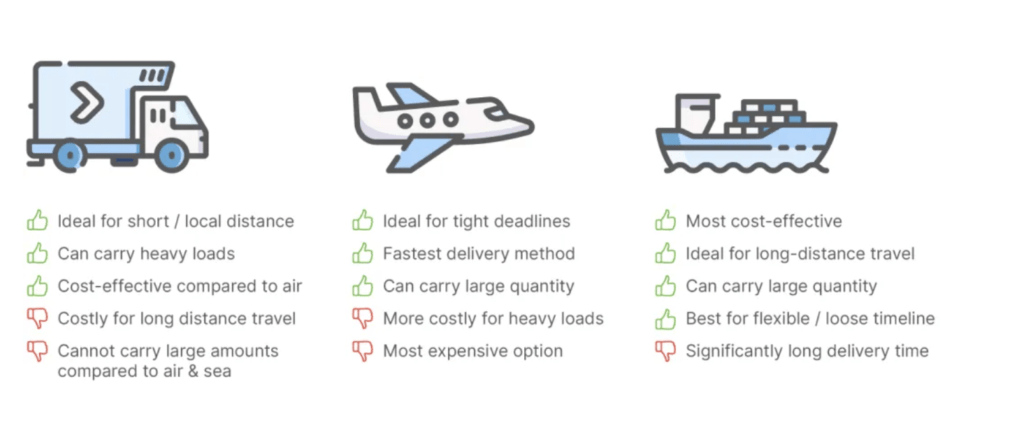

Volume planning is also highly dependent on your shipping method.

Different shipping methods will be more costly depending on how many units you have or the overall weight of your packaging.

Making sure your packaging dimensions, specifications and weight fits within your chosen shipping budget will help you determine the optimal volume for your first order.

For large orders it is recommended that you request a custom sample and go through a CTP Proofing stage.

This will allow you to confirm both the structure and printing for final production.

Requesting a prototype also gives you the opportunity to interact with your packaging before giving manufacturers the green light for production.

Prototypes do in fact help you save on costs, even though you will have to pay a price for the sample itself.

Why is this?

Well, catching errors on your packaging, whether these are small or large, will prevent you from having to do complete product recalls in the long run.

Imagine this, your packaging looks great on paper, but once your product is launched your customers receive damaged products, notice functionality issues and catch spelling mistakes.

It will not only be costly to carry out complete product recalls and produce a whole new batch of packaging, but it could be detrimental to your brand reputation.

Ordering custom samples is a small price to pay in order to ensure successful packaging that will be budget friendly in the long run.

Printing on a Budget

The main reason businesses are drawn to custom packaging is the ability to custom print your branding.

Depending on your order quantity, you can save on printing costs as well.

Offset and digital printing are both great options but depending on your quantity, one can be more cost-effective than the other.

For low run projects, digital printing is your best bet for cost-effective printing solutions.

However, keep in mind that the color accuracy might not be as high quality compared to offset printing.

Offset print uses metal plates to layer color onto sheets in a rapid succession and stamps designs directly onto the substrate.

This is also how newspapers and magazines are typically made.

It offers superior image quality and cost efficiency for large-volume print runs, but is too expensive for most low-volume projects and takes extra time to complete.

Digital print, on the other hand, is how your home office laser or inkjet printer works.

It offers quick turnaround times and makes low-volume jobs affordable.

However, digital printers can’t quite match the color fidelity and material flexibility that offset printing offers.

This is not to say that digital printing is not an option for you to consider, digital printing still does a great job at printing more simple and minimalist designs.

The best approach to keeping printing costs low and packaging quality high, would be to request a digitally printed prototype and produce your large volume orders with offset printing.

This will keep your printing costs lower, while still offering the opportunity to proof your packaging before investing in the higher quality version.

Corrugated packaging can benefit from either digital or offset.

Offset is preferable for designs that require additional processes such as spot UV and foil stamping and require a volume of over 1000 units.

For smaller runs and simpler designs on e-commerce packaging, digital is the way to go.

For Paperboard packaging, offset printing is advised, especially for cosmetic, pharmaceutical and small retail packaging.

Why?

Offset provides a clearer and more vivid printing output for smaller texts and designs.

Maintaining clear and concise information on your packaging is crucial for communicating important information with consumers, so it’s important your text is easily legible.

Read more on digital vs. offset printing for packaging

Making a decision on your printing method is just the beginning of comparing and contrasting printing costs.

You also have to determine where on your packaging you will be printing, and this is very dependent on your industry niche!

If you are an e-commerce company, you probably won’t need to spend much of your budget on the exterior of your packaging as it will likely see some wear and tear during shipping.

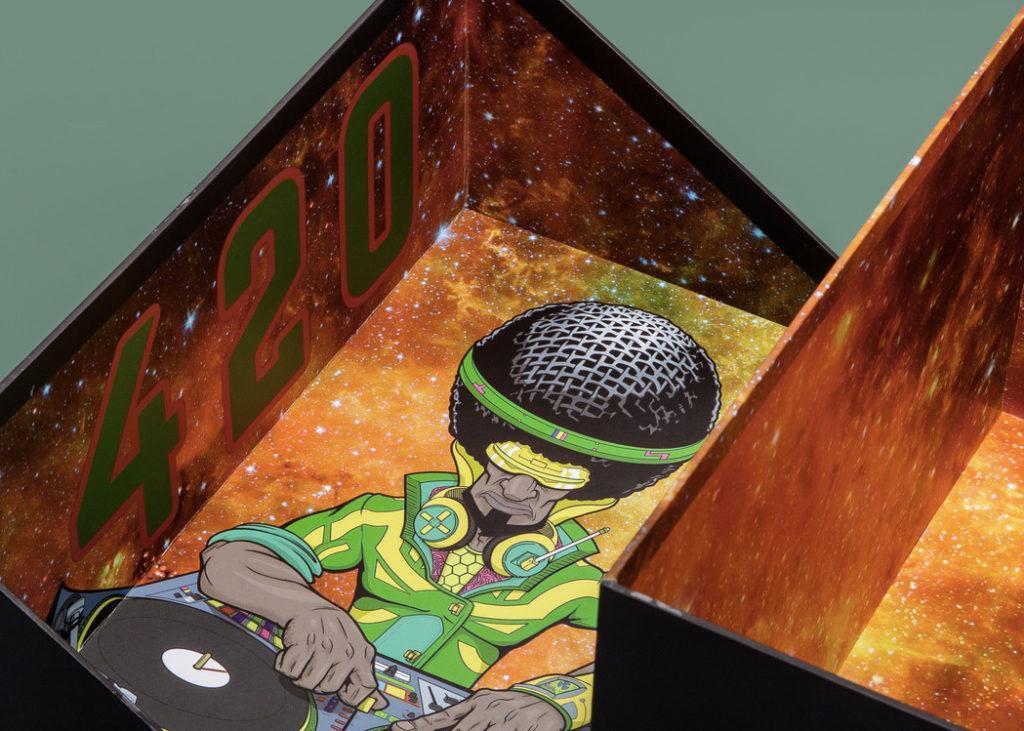

Interior printing or two-sided printing is a unique option that will keep your brand at the forefront of the entire unboxing experience, rather than just during the initial interaction.

Not only is interior printing a great way to save money, but you will also be cutting down on resources used when constructing your affordable boxes.

Interior printing allows your packaging to act as a direct vessel of communication to your customers.

Think of it this way; if you’re running an e-commerce business, your packaging will blend in with the rest of the boxes waiting in the mail room to be collected.

The unboxing experience is where you optimize the opportunity to make a lasting impression on your customers.

When your customers open your box, the interior will jump out at them and maybe even prompt them to share their experience online. In turn, gaining your brand and products more exposure!

Choosing The Right Manufacturer

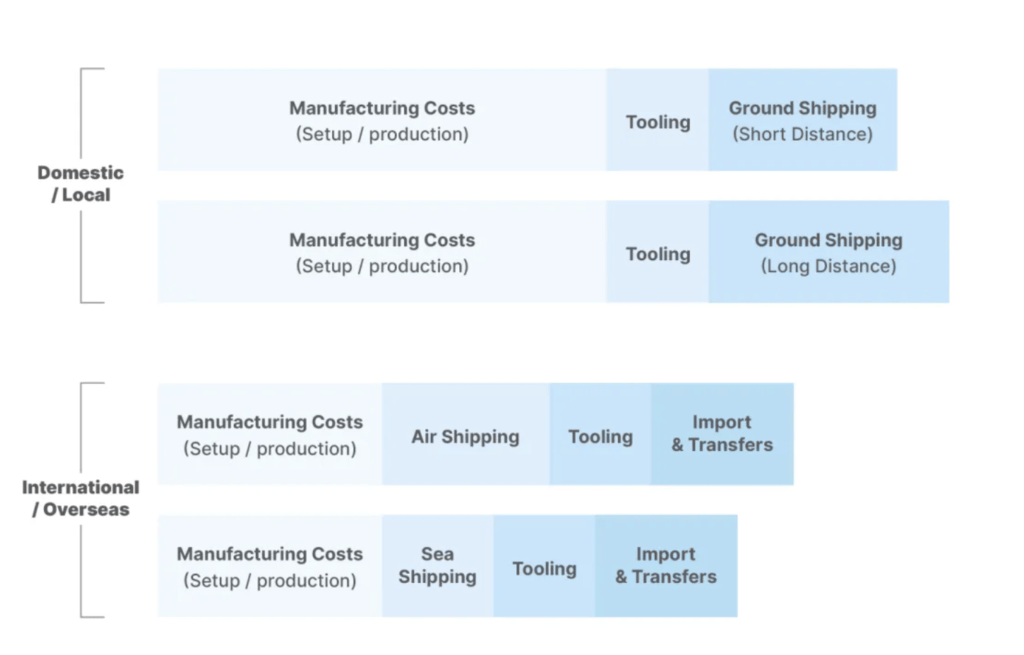

Where you manufacture your packaging matters!

Each manufacturing network comes with its own set of expertise, certifications, and processes so it’s important to compare and contrast to decide where you want your packaging produced.

In addition to their certifications and offerings, determining whether you’d like to work with domestic or international manufacturing companies is another thing to keep in mind.

Deciding between domestic manufacturers and international manufacturers will depend on the price, quality, and other specifications of your project (e.g. sustainable efforts, shipping method, etc).

Let’s delve into an example below to give you a better idea of what you should be looking for when choosing a manufacturer.

Take Factory A and Factory B for example:

While Factory B seems appealing in terms of time frames and printing qualities, it doesn’t give you a good understanding of what the manufacturing certifications and process looks like.

Factory A, on the other hand, gives you much more insight into how your packaging will be handled as they are FSC certified, preserve sustainable efforts and, most importantly, maintain low error rates.

Keep an eye out for certifications like Factory A, these will help you save on unnecessary costs in terms of having to fix errors and dealing with the hassle of low quality manufacturing.

It also allows you to have more control over the environmental impacts of your brand and in turn enhances your brand narratives and initiatives.

Overall it is most cost efficient to work with a solution provider as they have the capability to advise on manufacturing processes and capabilities that serve your packaging project adequately.

Read more about choosing the right custom packaging company.

Saving on Costs Through Logistics Planning

Similar to how transportation has different routes to get from point A to point B, logistics assist in planning the most efficient packaging methods and routes that are inexpensive and punctual.

One of these factors is transportation.

Depending on your manufacturer’s location and your timeline, some options will be more efficient and cost-effective than others.

Your timeline and due dates will have a big influence on deciding what mode of transportation to use.

If your time constraints are strict, air shipment or ground transportation may be the best bet (of course, this also depends on the distance between your business and manufacturer).

Air shipping can be quite expensive depending on your packaging specifications.

Air shipping will charge by either dimensional weight or actual weight, depending on which is more expensive.

If your timeline is loose and flexible, sea shipment will be the most cost-effective solution.

Sea shipping will typically charge you on the basis of volume, so opting for collapsible packaging will be beneficial as you can fit more boxes per pallet.

Lightweight packaging tends to be easier logistically and will likely cut down on your shipping costs.

Air and sea transport will be slower but will end up being cheaper for heavier goods.

Ground shipping will work nationwide, but product weight and dimension will change the costs in this case too.

To better estimate the shipping costs, think about how much it will cost to ship the custom box design and packaging based on the combined weight of your product and packaging as well as the dimensions.

Understanding the combined weight of the item and its packaging will help determine what your custom packaging shipping journey will look like and how much it will cost to ship packages overall.

We know custom packaging and custom boxes can be daunting when planning for cost saving.

Luckily, PakFactory has a wealth of experience in the field and is always happy to help you review and optimize your packaging options.