Natural Dry Press Molded Pulp Insert

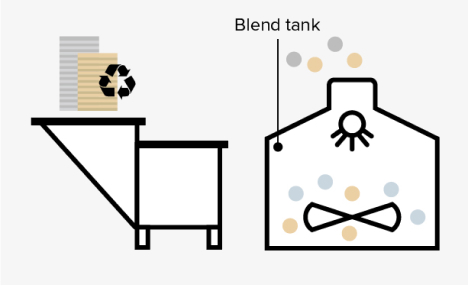

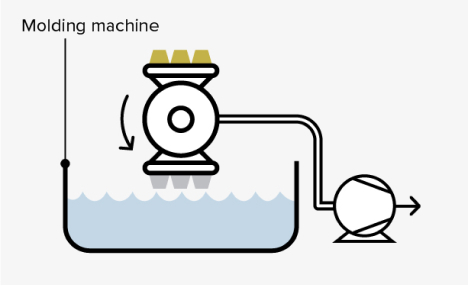

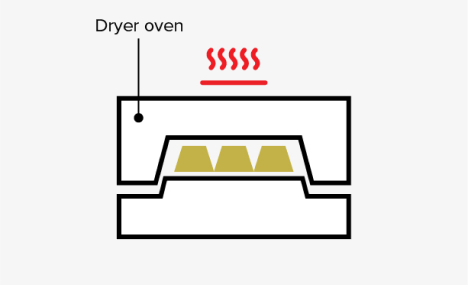

A natural colored dry press molded pulp insert. Finished in a semi-sooth texture and can be molded to your products precisely. An eco-friendly alternative for inserts.

Overview

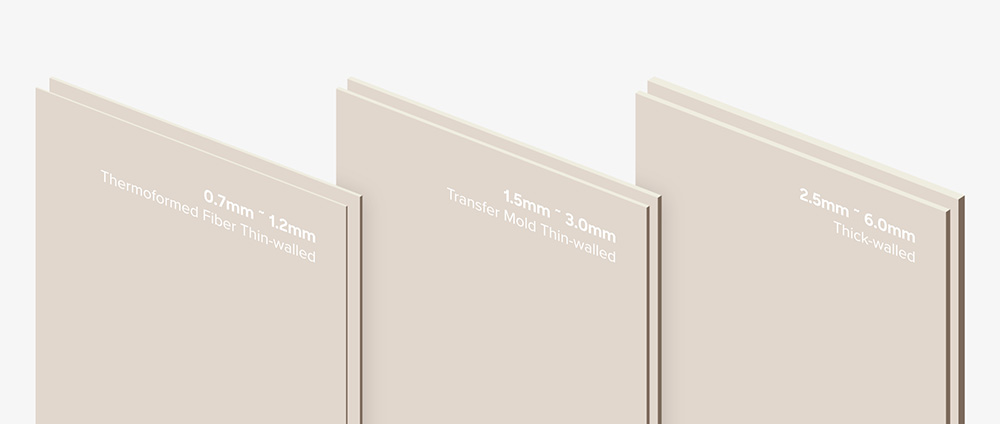

Custom dry press molded pulp inserts are 100% recyclable and provide exceptional support and protection to fragile and heavy weight products. Popular for packaging e-commerce products, electronics and certain food products, these inserts are shaped to your product, providing exceptional edge protection and structure which minimizes the risk of damage during shipping. Dry press molded pulp inserts are available in transfer molded pulp which features a polished surface ideal for creating protective custom box inserts that still adds to the unboxing experience of your products.

Our Ordering Process

Looking for custom packaging? Make it a breeze by following our four easy steps - soon you’ll be on your way to meeting all your packaging needs!

Customize your packaging

Choose from our vast selection of packaging solutions and customize it with our wide range of options to create your dream packaging.

Add to quote and submit

After customizing your packaging, simply add it to quote and submit quotation to be reviewed by one of our packaging specialists.

Consult with our expert

Get expert consultation on your quotation to to save on costs, streamline efficiency and reduce environmental impacts.

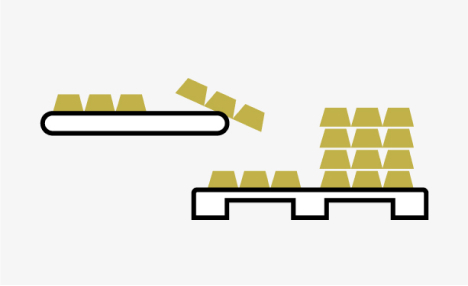

Production & shipping

Once everything is ready for production, have us manage your entire production and shipping! Just sit and wait for your order!