OPTION

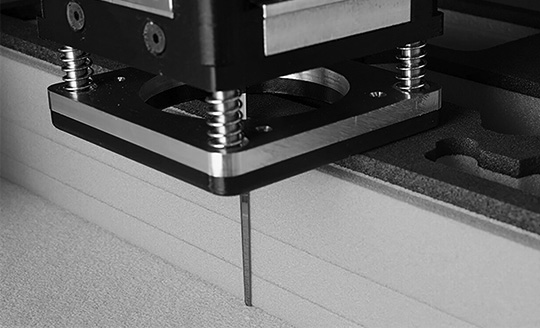

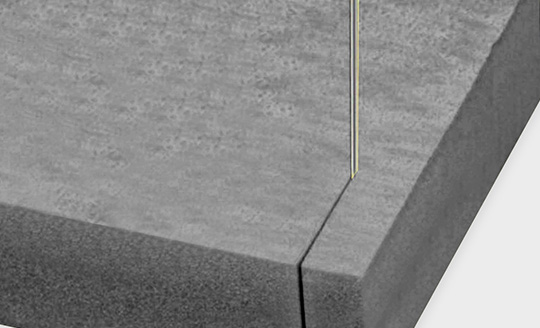

CI005

Egg Crate Foam (Convoluted)

- Most protective type of foam for small-large sized products.

- Superb protective characteristics against rough shipping and handling.

- Often used in breifcase packaging as a full sheet to protect the top face of your products.

Our Ordering Process

Looking for custom packaging? Make it a breeze by following our four easy steps - soon you’ll be on your way to meeting all your packaging needs!

Customize your packaging

Choose from our vast selection of packaging solutions and customize it with our wide range of options to create your dream packaging.

Add to quote and submit

After customizing your packaging, simply add it to quote and submit quotation to be reviewed by one of our packaging specialists.

Consult with our expert

Get expert consultation on your quotation to to save on costs, streamline efficiency and reduce environmental impacts.

Production & shipping

Once everything is ready for production, have us manage your entire production and shipping! Just sit and wait for your order!