PVC Blister Insert

When it comes to inserts, Polyvinyl chloride (PVC) is a top choice for many thanks to its lightweight and flexible properties. It’s perfect for customers searching for clear and durable inserts that can tolerate rough handling and moisture build up.

- Lightweight and flexible

- Clear transparent plastic for display purposes

- Poor heat resistance leading to harmful substances

Overview

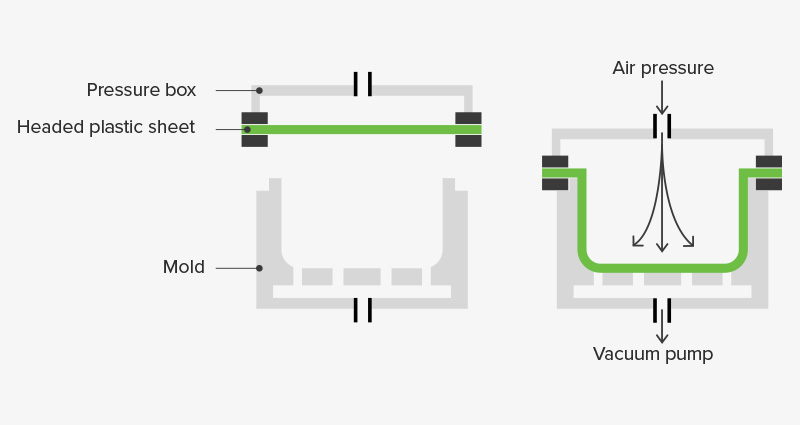

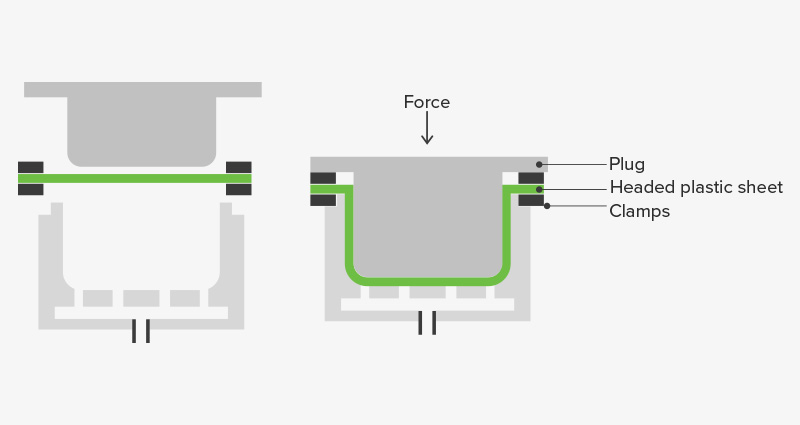

Polyvinyl Chloride (PVC) is the most popular material for producing blister packaging and box inserts at an affordable rate. Typically made using 0.25mm or 0.3mm PVC sheets this plastic box insert provides exceptional protection to smaller consumer goods. Commonly used in addition with corrugated boxes for the highest degree of durability, PVC blister plastic box inserts also provide optimal sealing and molding capabilities ideal for packaging food and pharmaceuticals.

Our Ordering Process

Looking for custom packaging? Make it a breeze by following our four easy steps - soon you’ll be on your way to meeting all your packaging needs!

Customize your packaging

Choose from our vast selection of packaging solutions and customize it with our wide range of options to create your dream packaging.

Add to quote and submit

After customizing your packaging, simply add it to quote and submit quotation to be reviewed by one of our packaging specialists.

Consult with our expert

Get expert consultation on your quotation to to save on costs, streamline efficiency and reduce environmental impacts.

Production & shipping

Once everything is ready for production, have us manage your entire production and shipping! Just sit and wait for your order!