What is corrugated cardboard?

When discussions about packaging arise, it’s easy to get confused with the many available materials that are out there. We’re all used to hearing the standard word “cardboard” in this context and generally, we don’t think much further than that. Here you’ll learn everything you need to know about corrugated cardboard.

Overview

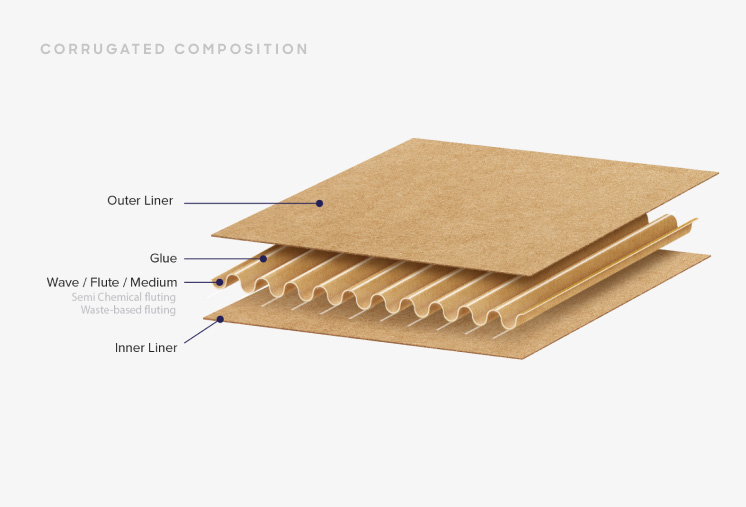

The conventional corrugated cardboard box has 3 fiberboard layers that make up its corrugated composition. The outer facing layer is the “outer liner”, the middle wavy layer is the “flute” and the inside facing layer is the “inner liner”.

The everyday corrugated box is most commonly used as a shipping box as the walls provide the much needed protection from the roughest of handling.

Corrugated vs. Carton

As we delve further into corrugated packaging and its uses, its essential to set the scene by talking about the key differences between corrugated versus carton and why its important.

Key differences

- Raw materials used for the packaging

- Weight

- Durability

- How the packaging is used

What are corrugated flutes?

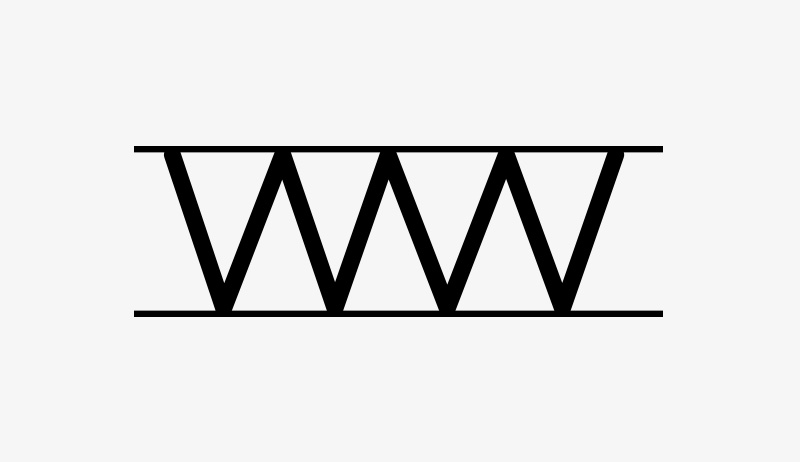

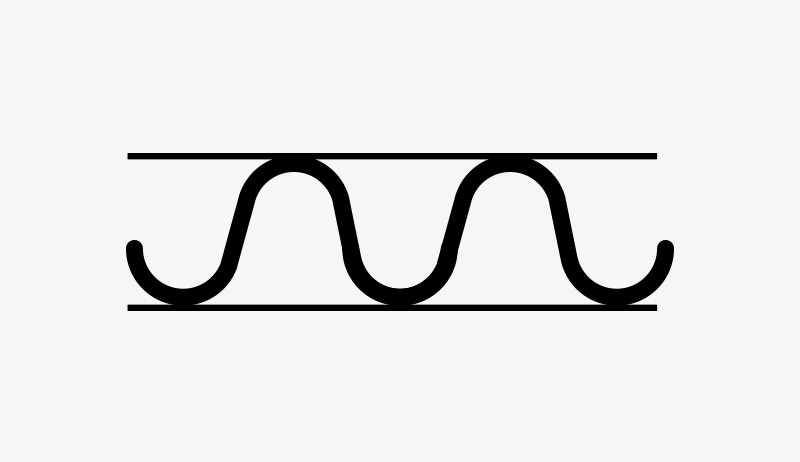

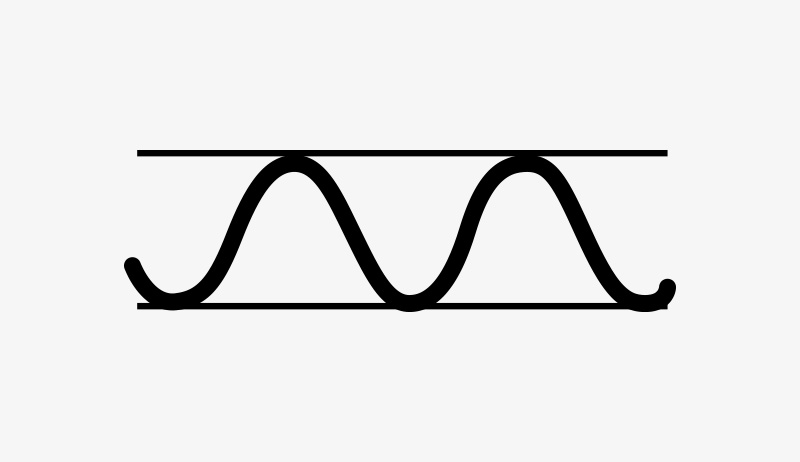

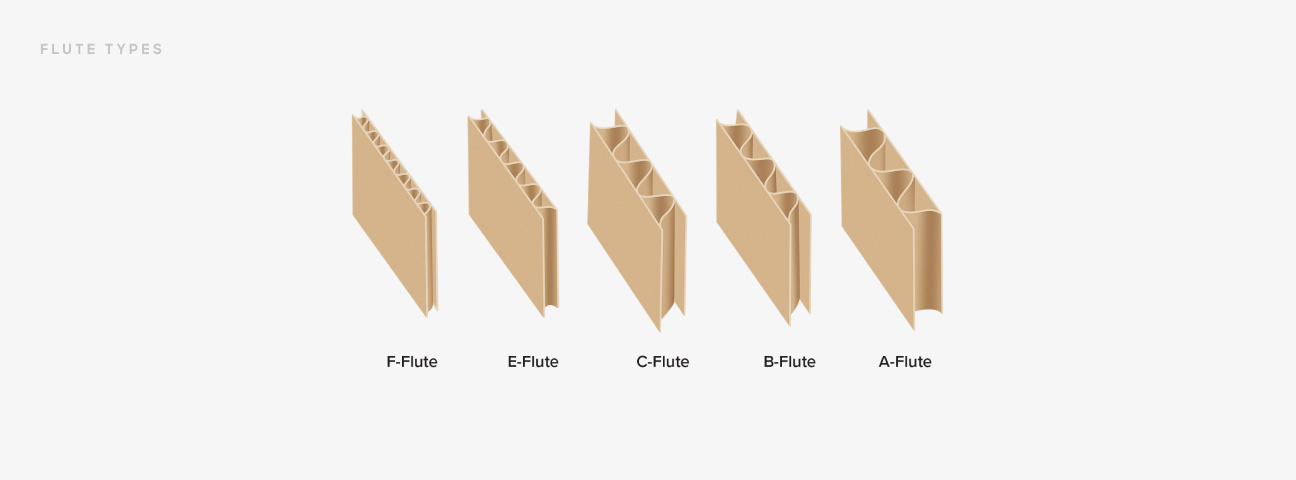

Flute, also called corrugation, is used to strengthen or reinforce the cardboard that's used in your packaging. They typically look like wavy lines which when glued to a paperboard, forms the corrugated board. Fluting in packaging gives your packaging the rigidity and helps withstand any crushing.

Flute Specifications

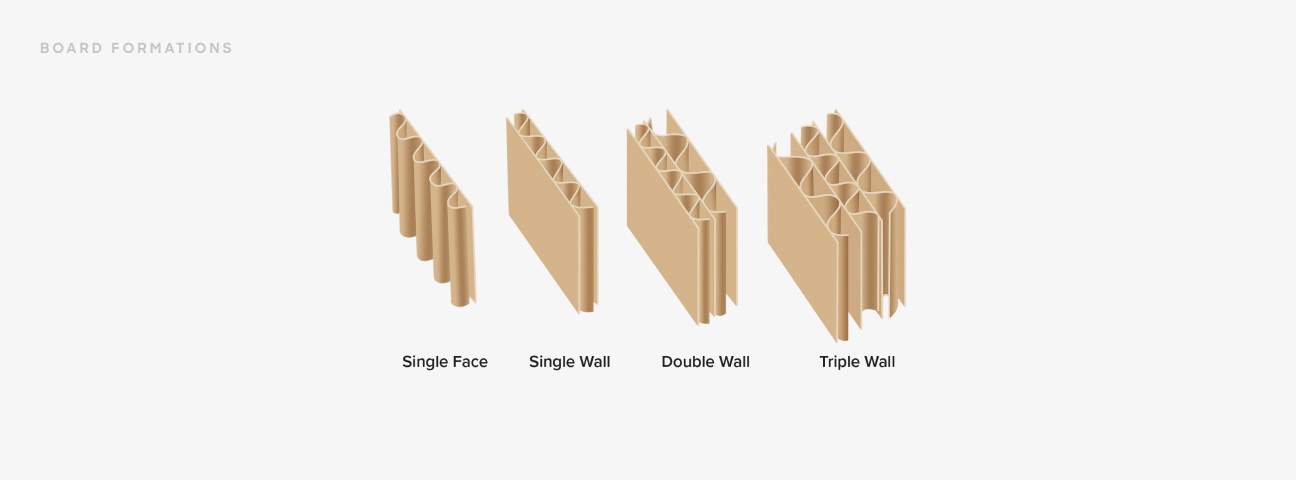

Corrugated Board Formations

Flute is categorized by thickness of paper being folded (fluting paper). This can range from single walled flutes, which are smaller flutes but provide better printability and foldability. Larger flutes, which are typically double walled flute and above, provide greater strength and cushioning, making them ideal for shipping.