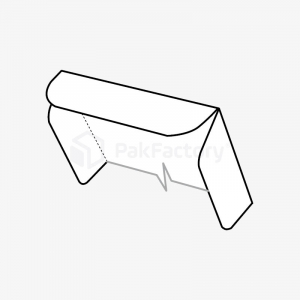

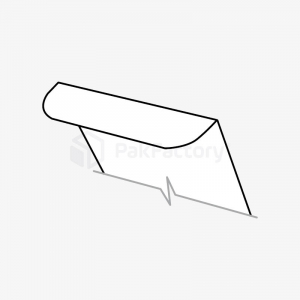

Roll Ends With Lid

Key Features:

- Fully customizable roll end with lid packaging boxes

- Unglued box that can be assembled and folded easily

- Dust flaps and cherry locks can be added for extra stability

- Ships flat and can be secured without staples or glue

- Best used for electronics and pharmaceuticals.

All of PakFactory boxes are fully customizable in size and design

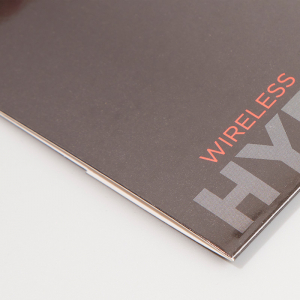

If your products are not packaged to maximize their looks on those retail shelves, then they might as well be invisible! PakFactory understood this need and has come up with packaging solutions that can tackle them. Introducing the custom roll end with lid printed cardboard boxes which are as versatile as they are durable. Designed to accommodate large print, high res graphics and brand colors, each can be personalized according to your business needs.

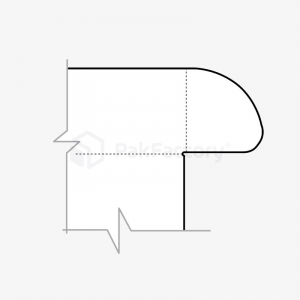

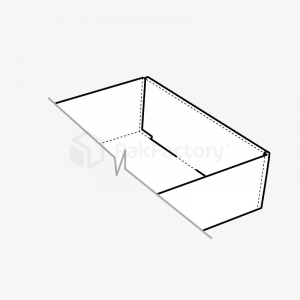

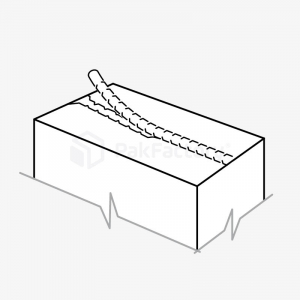

These boxes come with locking covers along with double side wall locking positions on the bottom panel. The lid panel features an extra locking flap which makes custom roll end with lid packaging boxes extremely sturdy and ideal for shipping purposes. This is one of the main reasons they are popular with electronic and tech dealers. All of them come unglued and just need to be folded to be assembled. The sides are corrugated for additional strength and can be customized with dust flaps as well as cherry locks for added stability.

The custom roll end with lid packaging boxes is pretty similar to PakFactory’s roll end tuck top but they are flatter. The sides can be folded over and the tab locks in place for secure closure. The self-locking design may be rigid, but custom roll end with lid product boxes can be set up in seconds. This makes them ideal for assembly lines where speed is priority. At PakFactory we offer a number of options regarding size, dimension and design so you can have your custom roll end with lid boxes created any way you want.

Box Features

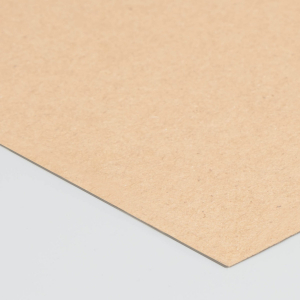

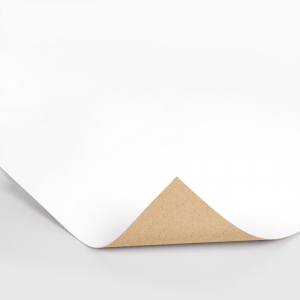

Materials

Printing Methods

Inks

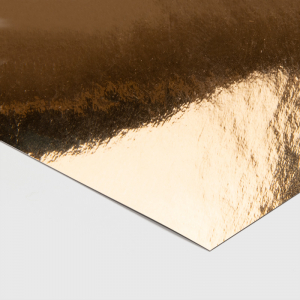

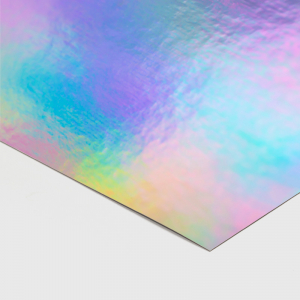

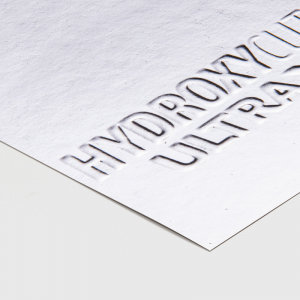

Finishing

Add-on

Our Ordering Process

Looking for custom packaging? Make it a breeze by following our four easy steps - soon you’ll be on your way to meeting all your packaging needs!

Customize your packaging

Choose from our vast selection of packaging solutions and customize it with our wide range of options to create your dream packaging.

Add to quote and submit

After customizing your packaging, simply add it to quote and submit quotation to be reviewed by one of our packaging specialists.

Consult with our expert

Get expert consultation on your quotation to to save on costs, streamline efficiency and reduce environmental impacts.

Production & shipping

Once everything is ready for production, have us manage your entire production and shipping! Just sit and wait for your order!