Table of Contents

If you’re looking for unique, innovative packaging that incorporates digital technology, look no further than smart packaging.

It offers a world of potential for logistics, quality control, and overall brand value.

Here we delve deeper into everything smart packaging. Smart packaging is still fairly new to the packaging industry, but we’ve already seen a huge impact on how it will affect the future of packaging.

Let’s start with the basics to give you a good understanding of what exactly smart packaging is!

What is Smart Packaging?

Smart packaging does not actually refer to one type of packaging; it’s actually an umbrella term for different types of intelligent packaging.

This type of packaging has enhanced functionalities and uses technology as part of the experience.

The addition of technology is used for protection and labeling and is now becoming part of the customer experience too!

Source: The Dieline

There are two types of smart packaging: active packaging and intelligent packaging.

We’ll look at each type of smart packaging individually before going into the overall benefits that it offers.

Types of Smart Packaging

Active Packaging

This packaging is a type of smart packaging within the smart food packaging market.

The packaging is designed in a way where it interacts with the contents inside the packaging and improves its shelf life and/or quality while being stored.

It can be designed to release certain substances into the medium, or substances can be removed from the medium.

Active packaging uses light filtering materials, oxygen and ethylene absorbers, antimicrobial surface coatings, or moisture-regulating materials, either by adding them into the packaging or as an insert.

This type of packaging can be a major benefit in food and beverage products and is an excellent addition to the active and intelligent packaging market.

Active packaging can add value to the product without detracting from the look and feel of the brand narratives.

Intelligent Packaging

Intelligent packaging, like active packaging, offers benefits for the consumer in different ways.

Used in the smart food packaging market, there are many types of intelligent packaging that can monitor products and ensure consumers receive items of the best quality.

How does intelligent packaging do this?

Through additions in the packaging that essentially communicate with the environment around it and the outside world.

This could be in the form of indicators, sensors, and diagnostic functions that continuously monitor the product and provide information.

Source: Unite AR

Sensors can also be integrated into the packaging or placed on the outside or inside for monitoring purposes.

Intelligent packaging is beneficial for both retailers and consumers because they receive real-time information about the product and catch key issues such as leaky packaging, bacteria, and temperature disruptions based on the sensors and indicators used.

Now that we’ve established the main types of smart packaging, we’ll take a deeper look at the smart packaging market and explore the top 10 things you should know about this innovative integration.

Connected Packaging

Connected packaging is a type of intelligent packaging that allows customers to interact with it.

Using a code activated by a mobile device, connected packaging has many applications in the retail world.

Brands can use it to deliver exclusive content and information on the product and how to use it.

As an example, Smashbox Cosmetics used conductive ink on a card included with their eyeshadow packaging, inviting customers to a website.

Customers would type a short URL into their mobile device and touch the connected card to the screen to do so.

It was a simple yet effective way to add additional value to the product and create a better customer experience.

According to Smithers, smart packaging sales grew from $4.95 billion to $6 billion between 2015-2019 with an average annual growth rate of 5.1%.

It is estimated that smart packaging will continue to grow to $8.6 billion between 2020-2025 at an average annual growth rate of 6.4%.

Already it is evident that that innovative packaging strategy is gaining lots of traction and we can definitely expect to see more of these innovations hit the shelves as time passes.

Ongoing research is looking at making smart packaging such as sensory labels more widely available through efficient production processes.

2. Logistics at the Forefront

As smart packaging continues to be researched, it requires a deeper dive into the logistics chain and how it can support these different packaging elements.

Many types of intelligent packaging can be supported, but the transport industry will need to evolve alongside it to make this type of packaging a staple on retail shelves.

Source: Graphiline

The transport industry has quickly evolved into using real-time tracking and tracing. RFID chips and other technology.

It is safe to say that we will continue to see new logistics strategies incorporated into individual packaging soon enough as the logistics and transportation industries evolve alongside packaging trends.

3. Quality Control

Quality control across industries has been a vital part of logistics and transport.

With innovations in the smart food packaging market and intelligent packing, quality control stands to improve even further.

The advanced sensors and indicators that are part of smart packaging will play a vital role in monitoring the product’s condition through the transport journey and when it’s on the shelves.

Shelf life of products can be extended through active packaging by removing unwanted particles from the medium and allowing clerks to keep track of expiration dates much more accurately.

The future of product quality will be a lot safer and easier to navigate as various types of intelligent packaging and smart packaging are introduced to the market.

4. Enhancing Brand Transparency

With more and more consumers demanding more sustainability, better ethics, and transparency from brands, packaging has to innovate to serve this demand.

The active and intelligent packaging market offers a way towards that.

Smart packaging provides better accountability and tracing on product packaging materials, carbon footprint, and manufacturing.

Brands can build a better connection with customers and create a more ethical brand that shines a spotlight on transparency.

Source: Behance

5. Counterfeit-Proof Products

Counterfeiting and fake products have been an industry issue for a long, long time and has caused a lot of mis-trust for many customers.

Luckily, intelligent packaging and smart packaging can offer a solution.

The technologies in intelligent packaging can provide more insight into product routes and manufacturing information.

Active packaging can monitor unwanted particles and tampering as well and mark deliveries as potential risks which then can be monitored more closely by businesses.

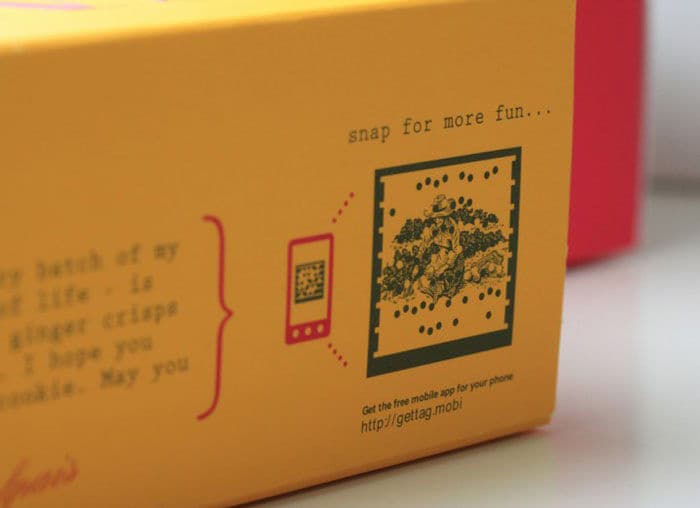

6. QR Codes

Dynamic QR codes are a part of intelligent packaging methods and offer a new level of interaction with customers.

Using technology such as a QR code, companies and brands get much better insight into who uses the QR codes, how often it’s used, and create further opportunities for customer satisfaction and loyalties.

QR codes can also be used in the manufacturing and supply chain process to monitor progress, reduce costs and errors, and optimize product performance.

All in all, QR codes have allowed for more convenience in the packaging industry.

Brands no longer need to plaster their packaging with mass amounts of information but rather add a decorative QR code that communicates on a more personal level with customers.

7. RFID Tags

RFID tags and tracking stickers have become increasingly popular, and for good reason.

They are used across different industries and products because they are vital to track inventory and supply chains.

Using intelligent packaging solutions such as RFID tags, companies can gain real-time insight into logistics and transport.

Passive RFID

Passive RFID tags don’t contain a battery.

They are powered by the reader using radio waves to activate a readable scan.

When the radio waves from the reader activates the passive RFID tag, the coiled antenna within the tag creates a magnetic field which then energizes the circuit within the tag.

The energy sends the information that has been encoded in the tag’s memory.

Active RFID

Active RFID tags are currently the most common of the types of RFID tags discussed.

The system is fairly simple as a battery powered tag carries an identification message from long distances at high speeds.

With more and more people using Bluetooth Low Energy (BLE), Active RFID tags are compatible with this feature which offers power and cost effective services.

8. Smart Packaging: Mutually Beneficial

The many types of smart packaging emerging highlight the opportunities present to reach customers and form the right experience from the start.

Customers’ long for more information and transparency. This can help speed up the adoption of the new types of intelligent packaging and smart packaging emerging in the market today.

This makes it a great option for both customers and companies, as long as the technology works quickly and effectively.

Source: Package Inspiration

Companies such as Saralon are working to create functional inks that can make printed batteries, displays, and sensors directly onto the packaging.

That type of innovation will lead to faster adoption rates and a better consumer experience overall.

9. The Disposal Process

One of the main barriers to widespread smart packaging usage is how to dispose of it.

Should smart packaging be considered electronic due to the components needed? If so, throwing it away as part of household waste may not work.

Manufacturers would need to be more explicit on the packaging itself to ensure that it is thrown away safely, which could prove to be challenging and costly.

Overall, the benefits of smart packaging and intelligent packaging are many. As the technologies involved continue to be studied and researched, it’s clear that the future of packaging is on its way to changing.

Want to learn more about packaging? We can help you with any packaging needs you may have!