Table of Contents

While 2023 just started a few months ago, the year has brought about some interesting trends within the packaging industry.

With e-commerce continuing to be a consumer preference, technological advancement and sustainability continuing to be a priority, the packaging industry has implemented and adapted to various industry trends worldwide.

Let’s dive deeper into what the packaging industry has experienced so far and what 2023 has in store for the industry, below!

1. Melding Technology and Packaging Solutions

Smart packaging does not refer to only one type of packaging; it’s actually an umbrella term for different types of technologically advanced packaging solutions.

Smart packaging offers valuable benefits of security, connectivity and authentication that businesses can easily monitor.

Especially with the pandemic leaving lingering effects worldwide, customers are looking for brands who can monitor and ensure the product they are purchasing and consuming are sanitary and haven’t been tampered with.

Active packaging: designed to interact with the contents inside the packaging to improve its shelf life and/or quality while being stored. Most common in food packaging to enhance shelf life of food.

Intelligent packaging: designed to provide more accuracy in communicating the quality of a product, product safety, and provide more valuable information about the product. Again, becoming more common in food packaging to communicate accurate ‘best by’ dates.

Connected packaging: designed for customer and logistics purposes. Things like QR codes and concealed URLs give customers the opportunity to actively interact with brands more conveniently. For example, Hershey’s was an early adopter of the transparency initiative with Smart Label.

Why are Businesses opting for Smart Packaging Solutions?

Smart Packaging is Gaining Market Share: Smart packaging is gaining market share fast, so being one of the early adopters will set your business apart from competitors. Smart packaging adds functionality, durability and convenience to not only your packaging but products too.

Enhanced Brand Transparency: Customers thrive to make authentic connections with brands that practice transparency. Connected packaging is the perfect way to give customers more insight into products while also keeping them safe and protected through QR codes and quality control processes using Intelligent packaging – a win-win.

Counterfeit-proof Products: With fakes and knockoffs causing concerns on the market, smart packaging can weed it all out and deepen trust between brands and customers by monitoring their packaging and products with RFID sensors.This allows businesses to ensure no counterfeit products will weave their way to customers.

Quality Control: Advanced sensors and other technologies can do constant Quality Control check ups on products from warehouses to the end destination, reducing worries and chances of missed revenue and damaged products.

2. E-Commerce and Digital Printing

While digital printing has been around for a while, the popularity of using this printing method for e-commerce packaging has started to gain much more popularity in 2023.

The reliance on e-commerce businesses has resulted in brands opting for more cost effective solutions in financially difficult times following the effects of COVID-19.

With brick and mortar stores seeing little business throughout 2020 and 2021, spending on high quality printing methods, like offset printing, have proven to be less effective with the exterior of boxes being damaged during shipping.

In 2023, digital printing has become an affordable way to create impactful unboxing experiences and create some brand differentiation in a world of brown boxes.

While packaging still runs the risk of damage to the exterior, the cost efficiency of this printing method makes it worth the risk.

It can be extremely difficult to create an experience with customers who are only interacting with your product through a screen.

The unboxing experience and brand differentiation are the main driver to maintaining a strong brand narrative that customers remember.

Digital printing is also much more time efficient giving brands the opportunity to create custom packaging in tighter time frames.

Although digital printing may have a reputation of being lower quality in comparison to offset printing, smaller designs like logos, patterns or shapes can benefit from digital printing as the quality difference is not exceptionally noticeable.

Furthermore, with sustainability initiatives on the rise, modern digital printing also has a limited impact on the environment as it eliminates the need for prepress procedures or additional labeling which, in turn, reduces waste and lowers inventory requirements.

3. Adopting Packaging Automation

The main challenges the packaging industry has faced are in relation with productivity, precision and quality control.

A large number of companies are still actively using manual packaging inspection processes, leaving plenty of room for errors in the quality of the packaging.

Manual packaging inspection is ineffective, risky and the result is often complete packaging recalls, costing businesses a huge portion of their budget.

The consequences of such mistakes has moved the packaging industry to automated production processes for more accurate results.

Especially in the ‘renaissance’ of e-commerce we currently live in, packaging needs to be structurally sound and durable in order to withstand any potentially harsh shipping and handling conditions.

In order for businesses to protect themselves and, above all, consumers, manufacturers have been investing a lot more in packaging quality control automation.

Apart from the separate control of each stage of product production, automated technology enables manufacturers to implement an all-in-one quality control platform that can be integrated with other systems and hardware.

The advantages of such a production system include a maximum return on investment, time efficiency, and increased customer loyalty.

4. Flexible Packaging

Flexible packaging is becoming increasingly popular in the packaging industry due to its numerous advantages over traditional packaging materials.

One of the key benefits of flexible packaging is its lightweight nature. Compared to heavier packaging materials like glass or metal, flexible packaging made from plastic, paper, or aluminum is much lighter, which translates into lower shipping costs and reduced environmental impact.

Additionally, flexible packaging can be designed to fit the product’s shape and size, providing a customized fit that helps to reduce the amount of excess material required, further lowering costs.

Another reason for the rise of flexible packaging is the growing demand for eco-friendly and sustainable packaging solutions.

Consumers are becoming more environmentally conscious and are looking for packaging options that are recyclable, compostable, or made from renewable materials.

Flexible packaging meets these criteria, as it can be easily recycled, reused, or repurposed, and can help reduce waste and minimize the carbon footprint.

Furthermore, flexible packaging offers superior protection and preservation of the product. It provides a barrier against moisture, oxygen, and light, which helps to maintain the product’s freshness and quality, extending its shelf life.

Flexible packaging can also be designed with additional features such as resealable zippers or spouts, making it more convenient for consumers to use and store the product.

As consumers continue to demand more convenient and sustainable packaging solutions, the trend towards flexible packaging is expected to grow.

The packaging industry is investing in new materials and technology to improve the properties of flexible packaging, making it even more attractive for a wider range of products.

With its cost-effectiveness, versatility, and sustainability benefits, flexible packaging is set to be a major player in the packaging industry for years to come.

5. Sustainability Initiatives

The packaging industry in particular, has seen many shifts over the years, especially as customer’s environmental awareness has increased.

With more scrutiny over sustainability and regulation, the packaging industry has had to quickly evolve to assuage consumer concerns and ensure that they are operating in an environmentally friendly way.

However, doing so has also caused a lot of confusion for businesses and corporations, as they try to balance their own interests with sustainability and public demand.

In addition, sustainability regulations around packaging have also become increasingly ambitious, adding another challenge for businesses trying to improve on their environmental impacts.

While there are many measures in place to support sustainability initiatives, it still cannot upend the dependence on plastics.

In order for sustainability in packaging to take off, waste collection, recycling systems, and technology would need more improvement to support the changes in materials and disposal methods needed.

2023 has brought the future of packaging into question and has started to push companies to begin incorporating sustainability into their strategies, especially in packaging.

6. Replacing Plastics with Bio-Plastics and Paper

Despite the long-standing dependence on plastics, alternatives are gaining popularity and challenging this dependence.

Bioplastics have emerged as a promising alternative, but research has shown that they still pose environmental risks similar to plastics, including difficulty in recycling and high resource consumption during production.

Similarly, while paper has long been considered an eco-friendly option, increased usage may lead to deforestation and other environmental issues.

The use of non-sustainable coatings on paper-based products has also raised concerns about their recyclability.

These insights have led to increased innovation in the sustainable packaging industry to find fully sustainable solutions.

Businesses need to consider the materials and coatings used, how they are derived, and their end-of-life to fully understand the environmental impact of packaging materials.

7. Designing for Reuse

The conversation around reuse tends to be much more difficult to initiate versus recycling because it requires a behavior shift.

The concept of reusing packaging hasn’t come up as often, and it’s likely very unfamiliar to most consumers.

However, there has been a huge shift in consumer behavior in 2023 with many looking for reusable solutions for the products they purchase.

While the idea of sustainability through reuse has been around for a while, this consumer trend is definitely getting much more attention now than it ever has.

This consumer trend has pushed many businesses to design their packaging and products with the purpose of reusing it after purchase.

While this is in fact beneficial for both customers and businesses, many smaller businesses have found it difficult to serve this demand, as reusable packaging tends to be more expensive to maintain.

Creating packaging designed for reuse requires thoughtful consideration of materials and structure that can withstand repeated washing and use – without damaging the environment.

It has recently become clear that products designed for reuse today tend to be bulky and actually incur a high environmental cost when created.

For example, remember when metal straws were a huge hit to save the turtles?

Well, it has come to light that the environmental cost of creating metal straws was just as harmful to the environment as disposing of plastic ones.

Although reuse plays a huge role in the future of sustainable packaging, it has experienced similar scrutiny in 2023 as consumers become more aware of the impacts of reusable products.

Customers now need to see much more value in the reuse of products and packaging in order to buy into the sustainability initiative behind it.

Businesses are now investing more in innovations in reusable packaging designs that do more good than bad for the environment, to better serve consumer demands in long term sustainability initiatives.

8. Designing for Recycling

While recycling has been the main topic of discussion in the emergence of environmentally conscious consumers, there has been an overwhelming increase in awareness of recycling, which is always a good thing.

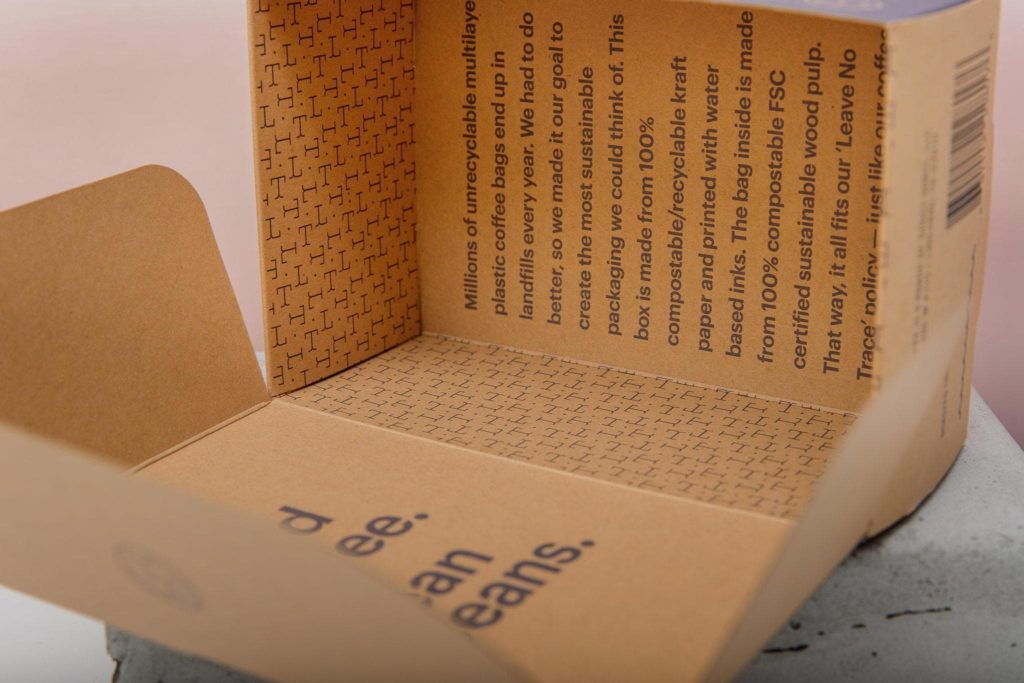

However, the truth is, businesses will attempt to make environmentally friendly changes to their packaging materials like opting for kraft paper boxes rather than plastic yet use coatings and inks which completely change the material’s recyclability.

Designing for recycling includes looking at aspects such as inks, coatings and labeling for separation.

Although most customers report wanting easily recyclable packaging, there is less data on whether consumers actually follow through after receiving the packaging.

Like with reuse, there is a certain shift in mindset needed which is slowly becoming more common in consumers.

Therefore, fully recyclable packaging is being pushed by consumer demands and many businesses are already taking steps to implement new designs around recyclability.

9. Using Mono Packaging materials

When we think about packaging, it’s likely that there are many different components in place.

Most packaging has multiple elements, including plastics, laminate, and other composite materials, making it difficult to recycle or reuse.

While some materials can be easily recycled, others cannot, making it challenging to create truly sustainable packaging.

In 2023, manufacturers have found a way around this by creating sustainable packaging materials that consist of just one single substrate.

However, this industry trend is likely short lived because without adding additional materials such as paper or plastic, the packaging becomes heavier and bulkier and may require other additives or materials to maintain its shape.

Doing so negates the potential positive effect on the environment, so it may not be the most realistic long term shift in the industry.

For mono-material sustainable packaging design to be successful, alternatives need to be looked at on a small and large scale to understand whether packaging quality is impacted and the net environmental impact before switching over completely.

10. Educating Customers

As alluded to earlier, a large part of sustainable packaging design is actually in customers’ hands rather than businesses.

Businesses can make drastic changes in sustainability, but they will not be truly successful if customers are not educated about impacts and their role.

Doing so can include education around recycling, disposal, awareness of sustainable packaging design in general, and general education around sustainability.

Consumers are becoming much more aware of the sustainability of packaging. However, with so much noise and information being spread online, things can become a little blurry.

This is why businesses are trying to take more ownership over the steps that need to be taken for sustainability to become an attainable attribute for their packaging.

The best way to balance sustainable packaging and consumer demands is to think about different informational needs and have something that caters to each type of person.

For example, some may just want a simple paragraph, while others may want more in-depth information around specific aspects.

Creating different channels such as websites, inserts, leaflets, and other materials can go a long way in helping customers understand their role in the process.

With the help of QR codes, businesses now have the capability of informing and educating their customers in much more depth.

Overall, it’s clear that there is considerable work going into improving sustainable packaging design and that packaging trends are heading in a more eco-friendly direction.

While there are still barriers in place around infrastructure and education, there is no doubt that strides are being made by both businesses and consumers.

With so much innovation in the packaging industry it’s difficult to say which ones will have the more long term impact on our current landscape. However, it is safe to say that the packaging industry is taking some pretty big steps in 2023 to serve consumer demands and increase packaging efficiency.

PakFactory has a variety of eco-friendly packaging options and services and are dedicated to tailoring packaging to your branding and business initiatives.