Table of Contents

With online shopping, brand differentiation is much more challenging as customers can only interact with images of your products. As such, it is crucial to add a personal touch through your e-commerce packaging and cater to customers’ unboxing experience!

Whether you’re looking for holiday themes or committing to an eco-friendly initiative, packaging is the most straightforward way to convey this to your customers. But before diving into the details and steps of creating your e-commerce packaging, we need to know the key aspects that lay the foundation for a successful customer experience.

Source: PakFactory

The Basics of E-commerce Packaging

E-commerce packaging serves three primary purposes: protecting your product, controlling shipping costs, and establishing your brand identity by catering to your customer’s unboxing experience.

First impressions are the most important, and while it’s true that customers first see your product on their computer screens, the first physical interaction is where it counts for customer retention. The unboxing experience is the true first impression of your brand.

Your customers’ expectations and anticipation are built from a simple digital image, but your business is responsible for meeting or exceeding customer expectations. How is this achieved?

It’s accomplished by choosing your packaging based on the purpose rather than the appeal. In other words, it’s what’s inside that counts.

The Key Objectives of E-commerce Packaging

Protection

The primary reason e-commerce-ready packaging is essential is because it protects what you’re trying to sell, which is a pretty simple objective. Shipping and distribution will be a stress-free process for your business, and many happy customers will receive their product undamaged and ready to be used.

Furthermore, well-protected products add significant value to your brand. There is no risk of refunds and exchanges, and it creates a strong impression that serves your brand well.

Source: PakFactory

Marketing & Branding

From a marketing and branding standpoint, e-commerce-ready packaging provides a lot of return if you make the proper investments.

Through the right design, you can create a meaningful unboxing experience for customers that they will never forget– which is vital for building brand equity with customers and differentiating yourself from competitors.

In today’s competitive e-commerce market, creating a strong brand image is critical to success, and packaging plays an essential role in achieving this.

The Importance of the Right E-commerce Packaging

Proper ecommerce packaging helps your business stand out. Wrong packaging choices can damage products, weaken brand connections and cause a loss of customer retention. As such, ensuring your packaging is the best it could be is crucial.

One of the better guidelines for creating e-commerce ready packaging is Amazon’s ‘Frustration-free packaging’ (FFP).

What is Frustration Free Packaging?

Frustration-free packaging is a type of e-commerce packaging designed to make the delivery process smoother and less stressful for both the customer and the seller. Frustration-free packaging is low waste, easy to open, and offers considerable protection during shipping without driving up costs.

It eliminates the hassle of opening a package using a minimalistic approach with simple yet practical designs. Frustration-free packaging also helps to reduce shipping costs, decrease the environmental impact, and improve the overall customer experience.

With frustration-free packaging, customers receive their orders promptly and efficiently, without any unnecessary stress or frustration, making it a win-win situation for everyone involved.

The First Steps of E-commerce Packaging

As mentioned earlier, packaging is just as important as the product in delivering a first impression. Custom packaging can assist you in creating a strong brand identity to impress your customers. Still, thorough research and planning are required to find ways to have your packaging complement your merchandise and brand identity.

If you are in the beginning stages of deciding on your first e-commerce packaging for your online products, we’ll help you determine which options work best!

But before focusing on a particular design, you must consider a few things;

- Determining your budget based on how much value your packaging can bring to a product will help lay the foundations for a successful packaging design.

- Adding value by promoting, protecting, and complimenting the respective product can boost your brand visibility and, in turn, your sales.

- Consider how many products you expect to sell in a given period and how much margin you can invest into your packaging.

- What is the target market, and how are your competitors packaging their products?

The above considerations will give you a good ballpark range of what your packaging, design, and shipping options will entail, allowing you to make a well-rounded, informed decision on your packaging options. Once you’ve considered all of the above, it is time to start thinking about how you’ll place the product in the packaging, as this will determine the structure of your box.

Source: PakFactory

For example, if you’re in the cosmetics or beauty business, placing the merchandise where its entire size, shape, and color can be seen without opening the packaging is common. Based on where you want to put the product and how much space it may occupy, you can now determine the measurement of your packaging.

Here, minimizing the dimensions and keeping the packaging lighter and smaller is best. Through structural engineering, packaging specialists can help you create packaging that leaves minimal space for your product to move around. This, in turn, will offer your products more stability and minimize the risk of damage.

Source: PakFactory

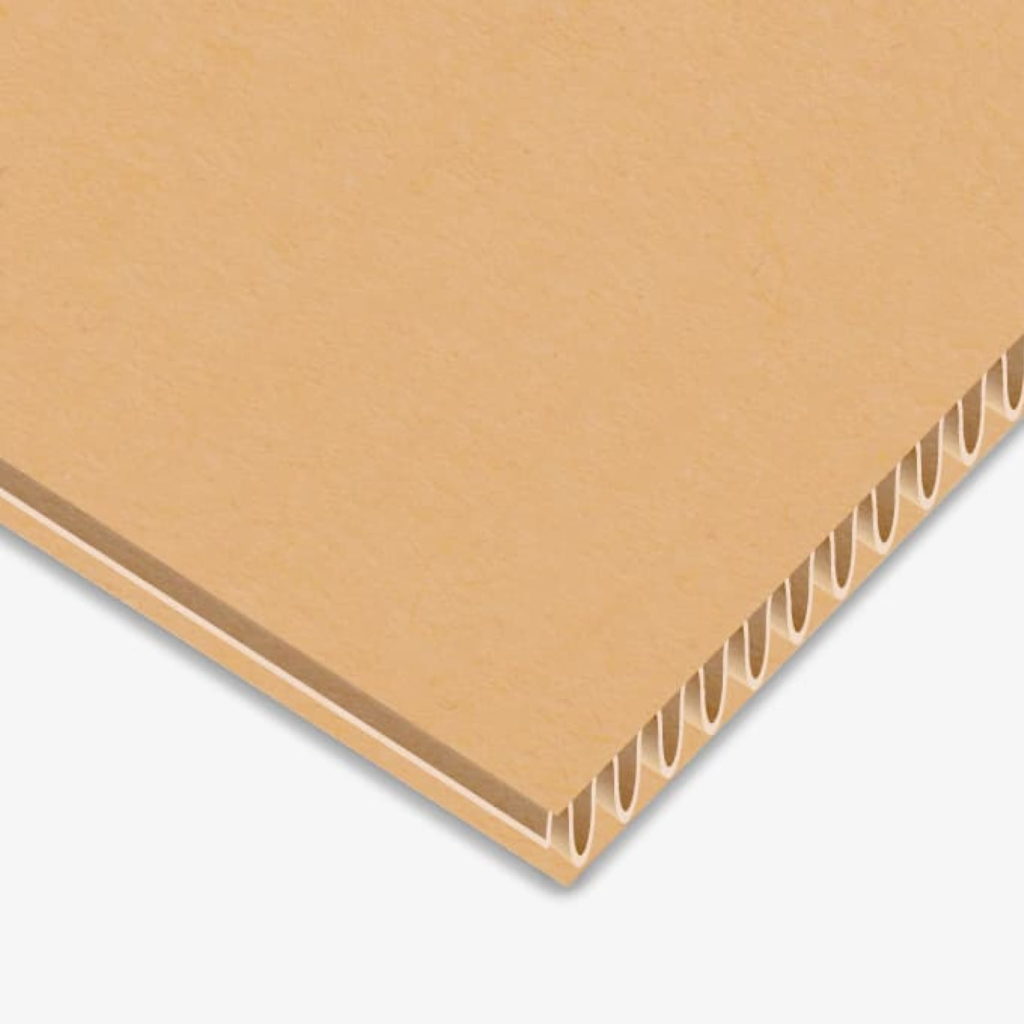

Exploring E-commerce Packaging Materials

After researching and planning the purpose of your package, it’s time to look at materials. Corrugated shipping boxes and poly mailers are the most popular packaging materials for e-commerce packaging. We recommend corrugated packaging as it is made from recycled materials, is very protective and can come in various shapes, sizes, and thicknesses, making it incredibly versatile for many products.

Material Stock Options

Choosing the right material stock depends on your artwork and your branding designs, but below are some of the available options:

- Natural White (Digital & Offset): For colorful and flood printing.

- Bleached White (Digital): Brighter output of colors to mimic offset printing slightly

- Kraft (Digital & Offset): Environmental and rustic look – perfect with black print, and no coating is required.

Read more on choosing your packaging materials

Material Thickness Options

Typically, manufacturers suggest the thickness of the paper based on the weight of your products and the dimensions of your box. It is still good, however, to understand what they are and how they can benefit your product.

E-Flute

The average thickness of the E-flute corrugated board is 1.2mm.

This type of fluting is ideal for packaging software, retail products, beauty products, food, and more.

B-Flute

The average thickness of the B-flute corrugated board is 3.0mm.

L x W x H = >570 anything more than this total dimension is B-Flute.

This type of fluting is ideal for packaging shoes, industrial products, furniture, and more.

Popular Packaging Styles

Now that you have a better idea of your material choices and thicknesses, you can start looking for the ideal structure to accommodate your product. Heavier and larger items require more protection to withstand harsh shipping and handling conditions. Some of the most popular cost-effective e-commerce packaging options are:

Roll End Tab Lock Corrugated Shipping Boxes

Source: PakFactory

The tab lock roll end box or mailer boxes are corrugated box styles that are well sealed, sturdy, and easy to unbox. These boxes are the most popular e-commerce packaging boxes due to their durable capabilities and unboxing experience.

Corrugated boxes offer versatile printing and finishing capabilities, allowing you to build an authentic connection with your customers!

Regular Slotted Corrugated Boxes

Source: PakFactory

Slotted corrugated boxes are your typical shipping box. This style is ideal for large and heavy-weight items needing extra support and care during shipping.

This type of box requires manual taping when put together, but this process is simple enough and can be done in a time-effective manner.

Roll End Tuck Top Corrugated Shipping Boxes

Source: PakFactory

Roll end tuck top boxes are shipping boxes that can be folded without hassle during assembly. The top of the package can open and close smoothly while ensuring maximum closure with a tuck on the inside.

These shipping boxes are ideal for;

- Catalogs

- Clothes

- Gifts

- Electronics

- Health products

- Beauty products

- Small hardware

Shipping Poly Mailers

Source: PakFactory

The poly mailer is a flexible packaging made from polyethylene LDPE or paper. Think of an Amazon bag or FedEx mailer – these are poly mailers. Padded envelopes are also considered poly mailers.

With poly mailers being light and versatile, they are a popular choice for e-commerce businesses that ship all types of light to medium-weight products. Unfortunately, poly mailers are not great for heavier products since they cannot provide adequate protection and support.

Still, this packaging type is cost-effective, tear-resistant, and usually waterproof!

Poly mailers have a self-seal adhesive strip for easy closure and are available with a padded interior or as a simple flat-packed bag, making packing and assembly a breeze.Read more on choosing the right package for your product.

Printing Methods for E-commerce Packages

Print quality significantly affects the presentation and overall look of your e-commerce packaging. While your package shape and size are essential to accommodating your products, printing is vital to accommodating your customers. Displaying clear and concise information is crucial to forming an authentic connection with your customers.

But because of the harsher shipping conditions e-commerce packages likely face, high-quality printing is not typically recommended for a box’s exterior as it will likely get damaged and tarnish the overall unboxing experience.

Instead, e-commerce businesses opt for interior printing or packaging inserts — more on this later. For now, the two main printing options for corrugated liner boards are digital and offset printing.

Digital Printing

Digital printing is the transferring of a document on a desktop or digital storage to a particular printing substrate through a device that accepts graphics and text output. The printer’s ink is then printed directly on the packaging material, working similarly to the average printer you use at home or the office.

Digital printing is perfect for low-quantity orders and is far less expensive than other printing methods since no printing plates and dies are required.

We mentioned earlier that it is not recommended to print on box exteriors. However, digital printing is advised if e-commerce businesses are looking to print on the exterior of their packaging. Since digital printing is much more cost-effective and time-efficient, e-commerce businesses can afford the risk of potential damage in return for a bit of brand differentiation.

Still, try to keep your artwork as minimal as possible regarding details and colors. The simplicity will provide a better output quality when printing digitally. Having too many small details and lots of colors in digital will fog the overall quality of the artwork and can end up looking low quality.Digital printing is the best for low-quantity orders as it is the most time-efficient and cost-effective printing method. Check out our digital printed corrugated boxes here: PakFactory’s Digital Corrugated Boxes

Offset Printing

Source: PakFactory

Offset printing is a printing press technique that transfers the ink from a plate to a rubber roller (or blanket) and then to a paper material. It is typically used for printing large quantities of;

- Newspapers

- Brochures

- Stationery

- Magazines

- High-quality boxes

The setup costs are expensive for offset printing, but the quality is impeccable. Typically, offset printing is advised for printing on the interior of the packaging or packaging inserts for optimal color output and quality, but due to the set-up costs being so high, it’s best to opt for offset printing if you have a high-quantity order.

What makes offset the desired choice for printing is its ability to print in PMS Color and produce unique printing processes such as;

Check out our off-set printed corrugated boxes at PakFactory’s Freedom Offset Corrugated Boxes or read more on printing methods.

Inserts and Additions to Your E-commerce Package

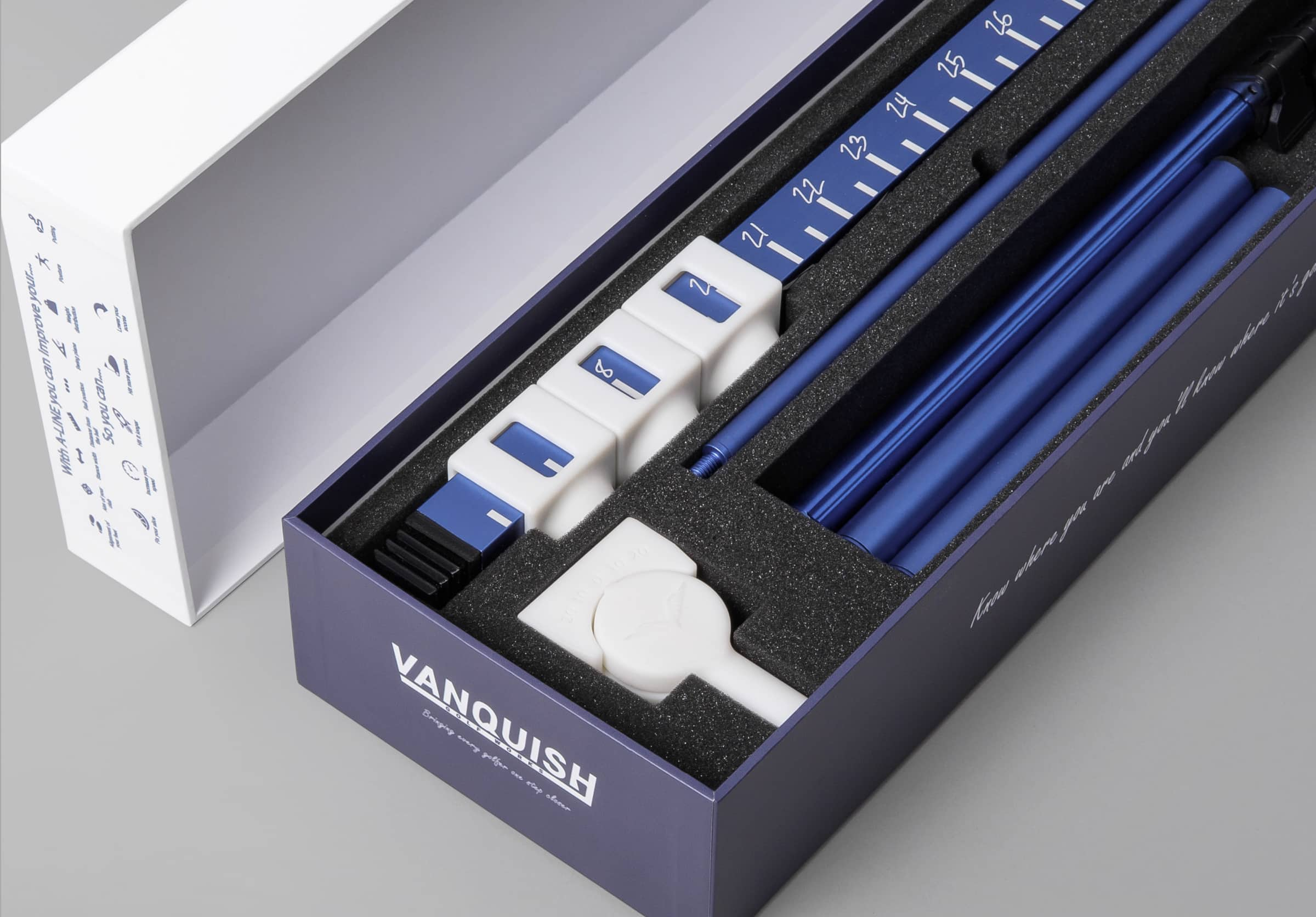

Adding additions and custom box inserts for protection or promotional inserts for marketing purposes is also recommended for E-commerce packaging.

Box inserts offer extra support and durability for your products and allow you to enhance the unboxing experience. For lower quantity runs, consider standard-sized packaging options with inexpensive customized additions, such as;

Box Inserts

If you want to protect and organize your products, you can use cardboard or foam inserts to divide and protect your products. These types of box inserts will prevent your products from moving around in the box during transit.

Source: PakFactory

Box inserts also enhance your brand identity by offering a higher-end unboxing experience and are available in:

Promotional Inserts

Promotional inserts are one of the cheapest ways to promote your product and increase brand awareness, customer loyalty, and sales.

A custom message, cross-promotion or a simple thank you can be a powerful statement to reflect your brand’s narrative while improving your customer’s unboxing experience. Promotional inserts give customers the motivation to continue engagement with your products and an opportunity for them to get the most value out of your brand.

Furthermore, customers look to make an authentic connection with brands, and promotional inserts are a great way to work towards aligning your company with your customers.

Read more about custom packaging inserts.

Artwork Design for E-commerce Packaging

The printed design is the first thing customers see and interact with when seeing your packaging for the first time. Below are simple elements you can incorporate into your artwork to resonate with them.

Personalized Messaging

You don’t need fancy letters or designs to capture your customers’ attention. All it takes is having a well-thought-out brand narrative that shows off the personality and value of your brand. Speaking directly to your customers allows them to feel connected with your brand.

Unlimited Brand Color Scheme

What is excellent about custom-printed e-commerce packaging boxes is that you can use unlimited colors for your artwork without any additional charge. So, make sure to include all of the elements of your brand colors in your artwork to establish a unified brand narrative.

Source: PakFactory

Consider color psychology and choose which emotions you want to trigger based on your target market’s needs and desires.

Brand Logo

Your logo should be visible the moment a customer receives your box. This can be achieved through exterior and interior printing of your brand logo. Make sure to allow your brand name to stand out and be memorable to your customers. Making your brand logo the star of the show will enable customers to remember your brand and repurchase your products with ease.

Samples and Prototyping

Prototyping is one of the most critical steps in the packaging process. We highly recommend that a prototype is made to confirm the structure and printing of the final output of your packaging, as it avoids the issue of receiving hundreds or thousands of boxes with the wrong dimensions or inaccurate fit.

Unlike stock products, custom packaging is made specifically for your products and cannot be returned or refunded. An incorrect packaging batch will need to be written off and recycled, coming out of your costs and causing your company added stress and time to your product launch.

Get a physical CTP proof to check color and printing accuracy, and a non-printed sample can help ensure product fitment. Another great option is a physical prototype of your custom packaging, which is a one-off make of your packaging in either production or sample grade. Prototyping provides the closest experience to your final packaging, so don’t skip this step! Read more on why box samples are essential for your packaging.

The Production and Shipping Process

You will have minimal involvement in the last step of this guide. This step is when the manufacturer mass-produces your packaging based on your final packaging specifications. Typically, you will only need to find a freight forwarder to complete the shipment or ask the manufacturer to ship the product to you with their forwarders or by express.

There are four main ways you can ship your products:

- Sea Freight (Coming from overseas and typically the least expensive option for international shipping)

- Air Freight (Overseas or local, quickest and most costly)

- Ground Freight

- Express (Courier)

Logistics can be a daunting process, especially, if you are shipping internationally, requiring several documents for declaration, customs clearance, and policy. The benefit of working with a courier is that they can help you through the clearance process, while shipping through freight may require a bond to be purchased and renewed annually.

Et Voila!

There’s much to unpack when embarking on an e-commerce packaging journey, but don’t fret. It is entirely possible when you work with packaging experts during the planning and design process. Don’t let the processes overwhelm you — instead, see it as an opportunity to connect with your target market.

Understanding what your target market is looking for will enable you to create packaging that will help sell your products and attract new customers.

While starting your own e-commerce packaging project may seem troublesome, with proper preparation and support from reputable vendors, any business can achieve a professional e-commerce packaging solution.