Table of Contents

What would it look like if we had binoculars that could see into the future of packaging? Well, based on what we already know, it’s easy to imagine. By analyzing emerging technology, new packaging trends, and market projections, we can get a good glimpse into what the packaging industry might look like in ten years and beyond.

From sustainability and design to manufacturing and operations, service providers, not product sellers, are the future. This means that in the coming years, consumers will be able to enjoy an all-inclusive shopping experience where, instead of offering a few branded items, it will be customary for businesses to provide a full-spectrum experience that goes beyond a company’s brand and appeals to customers mentally, emotionally and sensually.

With technological advances, mass production will shift toward innovative, specialized brand packaging to serve specific products and services. Technology is on a clear track to merge with packaging, bringing forth a new revolution in the industry. So while we all recognize the classic cardboard boxes, bags, and bottles, the future may significantly alter them. But before examining specific packaging industry trends, we must look at the broader driving factors of the future: e-commerce and sustainability.

The Rise of E-Commerce and Push for Sustainability

Source: PakFactory

Initially gaining excellent traction during the early 2010s, the arrival of COVID-19 gave e-commerce a meteoric boost. With no in-store experiences or opportunities for the customer service industry during the lockdown, e-commerce is quickly on track to overtake traditional retail as the primary form of shopping.

The emergence of e-commerce as a necessary form of shopping has created vast opportunities for the packaging industry to specialize and customize their products to an even higher degree, especially with the new, innovative technologies for packaging.

With giants like Amazon leading the charge, the e-commerce shopping experience is becoming more and more tailored to the customer from beginning to end, which is why e-commerce is a major dictating factor in the future of the packaging industry. However, as mentioned before, it is not the only driving factor.

Maintaining the Planet

Sustainability is the second driving factor for the future of the packaging industry. Beyond packaging, sustainability was already an evident trend within many industries. Consumers were already leaning towards a more eco-friendly shopping experience, and this initiative is becoming more normalized as time passes.

And while eco-friendly options are currently less cost-effective, consumer spending on eco-friendly products is still rising. According to Survey Monkey, 1 in 3 consumers favor eco-friendly options, and 35% of respondents would purchase a product that is better for the environment over other products that may be slightly cheaper.

With more companies taking up the mantle of environment protection and savvy consumers who now expect a higher level of eco-responsibility, sustainability has already become a strong focus for the packaging industry.

Trends like waste reduction, efficient use of box space, lower carbon footprint, and recycling have already begun rising in popularity, and this will only continue. Because of this, sustainable packaging may be the new norm that overrides traditional and still abundantly used plastic packaging.

Source: PakFactory

In envisioning the future of packaging, one undeniable shift is the fall of plastic materials. Plastic has been a popular choice for its convenience, durability, and widespread use, but it has faced increasing scrutiny due to its environmental impact. The harsh reality of plastic pollution has awakened a collective consciousness, urging consumers and businesses to seek more sustainable alternatives, leading to embracing innovative technologies and materials for a better, healthier planet.

New Tech Packaging: Innovations of the Future

So with growing consumer demands for everything to be as convenient and eco-friendly as possible, like with the popularization of e-commerce and sustainability, innovative upgrades and technological advancements are necessary to unlock new opportunities for businesses to capitalize on.

Luckily for them, the industry is amid a technological renaissance, with new packaging designs and innovations constantly being introduced into the market. But what are some of these new packaging technologies we are referring to? Let’s dive in and find out!

Edible Alternatives

Source: Wen Wen Fan

Edible packaging is an innovative, sustainable alternative that alleviates the reliance on fossil fuels and has the potential to significantly decrease our carbon footprint by reducing our dependence on plastics. With consumers pushing for eco-friendly initiatives, this is the perfect solution to what they are asking for.

Using natural materials like algae, plant fibers, seaweed or crop, edible packaging shows a lot of potential for offering the food industry various versatile options for package colors, designs, and more. Consumers can even eat the package, which also serves as a unique experience while leaving no trace behind to end up in landfills or littered into the ocean.

But edible packaging isn’t limited to consumer consumption. Some edible packaging options can be consumed by animals, nourishing them instead of poisoning them like traditional plastics.

Space Saving and Flexible Packaging

Source: PakFactory

Innovations aren’t just happening with how consumers dispose of packages, though. Storage and transport are changing too. The mass production, transportation and storage of packaging are also environmentally harmful, as excess stock inevitably ends up in landfills. But thankfully, with recent innovations and increased efficiency, we are seeing an increase in space-saving solutions.

This means we are trending toward flexible packaging for stacking, storage, and efficiency. Especially for the food industry, where consumers crave convenience and versatility, flexible packaging is one of the top trends.

It is lightweight, durable, and incredibly adaptable to different product types and sizes. Whether it’s a resealable stand-up pouch, a convenient bag, or a handy sachet, flexible packaging makes storage, transportation, and consumption a breeze while minimizing waste and reducing environmental impact. Its efficient use of materials and innovative features like portion control and enhanced product protection make it a win-win situation for both consumers and the planet.

Smart Tech Packaging

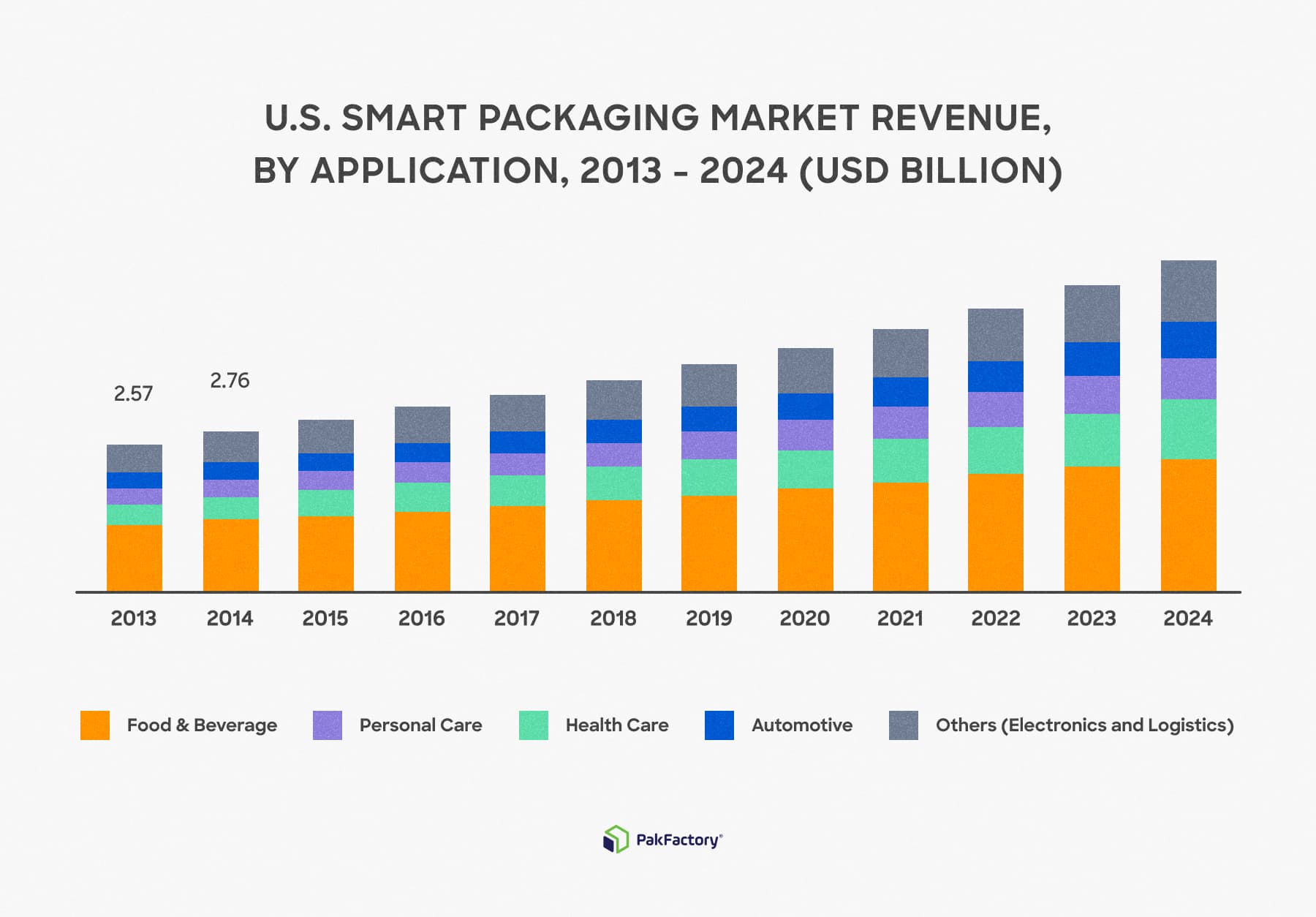

But if you thought edible and flexible packaging was advanced, you’d be surprised that even more advanced innovations are trending in the industry. Smart packaging, also known as intelligent and active packaging, has grown enormously in recent years. According to Grand View Research, recorded smart packaging revenues were $10.8 billion in 2015, with a projected surge to $26.7 billion by 2024.

Source: PakFactory

For brands and companies, smart packaging offers a new world of communication with the opportunity to conveniently track and record consumer behaviors to provide a more tailored experience for target markets, allowing businesses to meet consumer demands more effectively.

Technology like printed electronics in the form of near-field communication (NFC), radio-frequency identification (RFID), ambient intelligence, smart LEDs/OLEDs, and compact power sources, screens, sensors, and data storage offer consumers a level of interaction never seen before with advanced infotainment, digital sales aids, and online connection.

Nanotechnology is also seeing use to reduce packaging waste and sustainability, with bio-nano composites potentially replacing non-biodegradable, petroleum-based plastic due to its protective properties perfect for hygienic and antibacterial packaging, particularly for medical, pharmaceutical, and food products. We are just seeing the tip of the iceberg with nanotechnology, and we can expect more innovation to come.

Even augmented reality, for the longest time stuck in the realms of science fiction, is no longer out of reach. With the emergence of augmented reality (AR) technology, we’ve started to see the lasting role interactive tech will play in the future of packaging design. In the coming decade, consumers will be able to virtually test-drive products, examine packaging options, and interact with game elements as companies build brand recognition and provide new forms of entertainment through packaging and products.

Overall, smart technology will not only enhance the engagement of your product but will provide tons of consumer data that can help deliver more measurable results and benefits to customers.

Material Trends: Sustainable, Flexible, Corrugated

So we’ve covered the design trends and the rise of smart packaging, but what about the materials? Well, just like new packaging designs, materials follow the same driving factors of e-commerce and sustainability. We’ve already examined edible and flexible packaging as design trends, but their used materials are also worth highlighting.

Natural materials like bamboo, plant fibers and starches for edible and other sustainable packaging options are quickly rising in usage as a viable alternative to common packaging materials like plastic.

As for flexible packaging materials, though plastic is still used, these materials are experiencing strong growth. With the increasing presence of e-commerce, changing dietary habits, and abundant processed and packaged food, flexible packaging is still a viable alternative to traditional plastic packaging. This is because it utilizes fewer materials resulting in less waste, takes up less space during transport and allows an increased shelf life for food and beverage products.

Corrugated materials are the last trending material, which might not be new but is still going strong. Valued at $155 billion in 2017, the global market for corrugated box materials is expected to double by 2025. This can be attributed to the booming e-commerce industry and the fact that although corrugated materials have flaws, they are still a solid choice for their strength, cost-effectiveness, and recyclability.

3D Printing Advancements in Manufacturing

It is not just the designs and materials changing in the packaging industry. Manufacturing is changing too. With advancing technologies and the discovery of new and efficient methods, making unique packaging has never been easier.

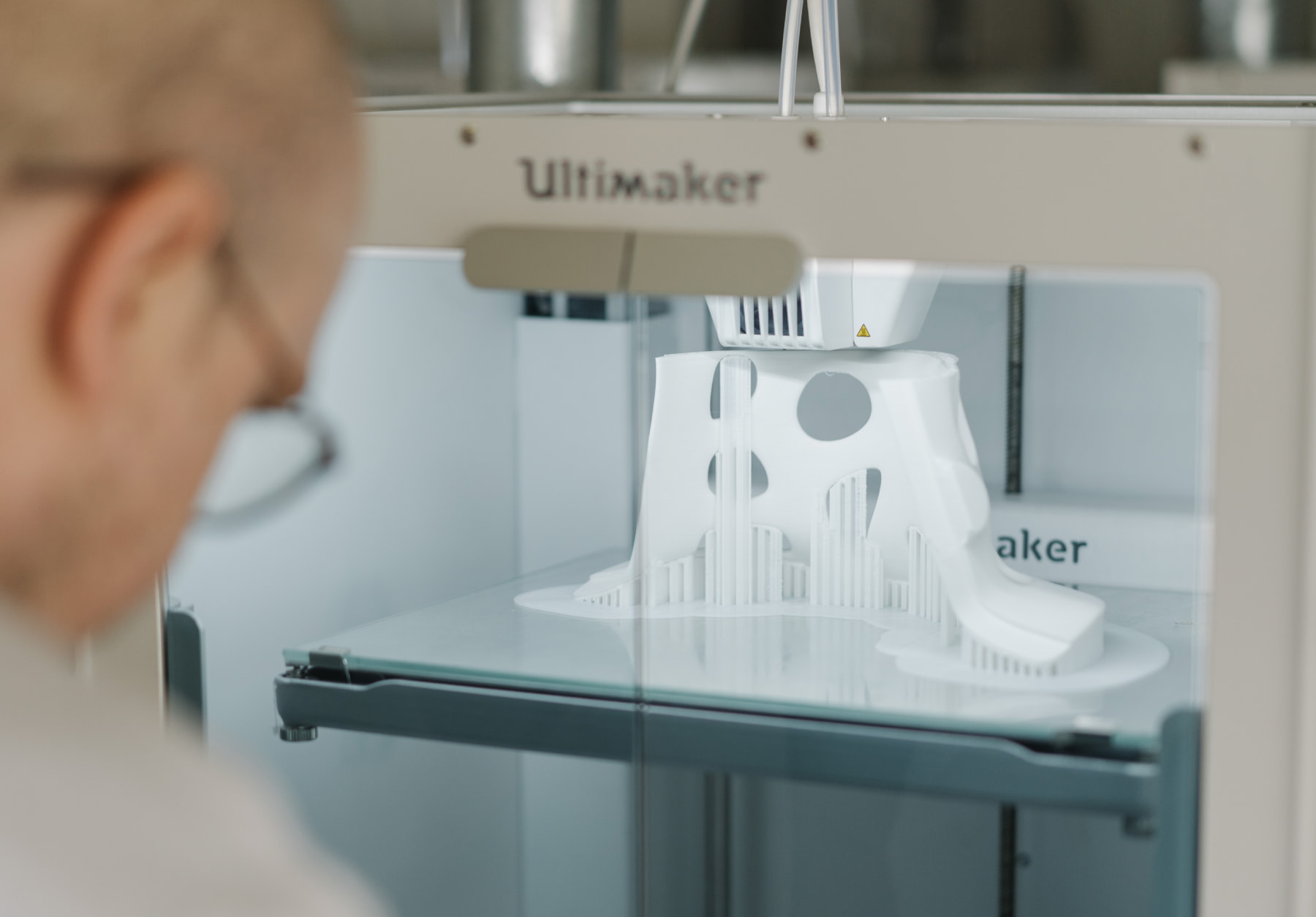

Source: Unsplash

Additive manufacturing technology has captured our imaginations over the last few years with its ability to create complex shapes and designs on demand, which would otherwise be unattainable or wildly resource-intensive through traditional manufacturing practices. In the future, 3D printing promises to raise the bar even higher via print-to-order manufacturing.

For packaging prototypes, 3D printing will provide a vastly superior option over current methods, offering flexibility, efficiency, and cost reduction that will meld the lines between design and manufacturing.

And although 3D printing is still in its infancy, expect to see a shift from limited specialized production to scalable printing for all sorts of industries soon! As early as 2028, additive manufacturing processes will offer personalized on-demand package solutions limited only by imagination.

Smart Warehousing With AI & Machine Automation

We mentioned smart packaging earlier in this article, but this new technology isn’t just limited to packages. With an increasingly connected world, consumers already expect made-to-order products to ship quickly. And with cognitive computing, robotic process automation (RPA), IoT connectivity, and other innovative technologies, this is possible.

All of these technologies will come together to form a comprehensive fulfillment solution to meet the increasing demands of consumers via smart warehousing, which includes:

- predictive maintenance (instead of waiting for something to break, systems will anticipate and address it accordingly)

- cobots (robots that will work in conjunction with humans),

- IoT standardization (allowing for effective network connection)

- integration of print-to-order manufacturing.

As robots begin to take on more tasks, artificial intelligence (AI) and machine learning (ML) will become even more prominent in the future!

Blockchain Technology for Shipping and Logistics

Like the warehousing, manufacturing and packaging design sections discussed in this article, shipping and logistics are also experiencing a trend toward technological integration with their process in the form of blockchain technology. Although Bitcoin failed as a cryptocurrency, the technology behind it is primed to disrupt the packaging industry.

Source: Unsplash

Logistics costs in the United States come in at $1.5 trillion per year, and while growth continues, two significant issues are plaguing the industry: systematic inefficiency and fraud. Fortunately, we are witnessing the beginning of a revolution through blockchain technology.

By offering a decentralized digital ledger, blockchain will eliminate the need for intermediary shipping fees, paperwork, and other inefficient/vulnerable/wasteful practices. This will streamline the shipping processes while providing a level of tracking, security, transparency, counterfeit protection, and cost-effectiveness we’ve never seen before.

All parties involved, from shippers and carriers to brokers, vendors, and consumers, will soon witness and be directly affected by the rise of this transformative tech.

Automating Deliveries to Consumers

With all the innovations and technological advancements appearing in such a short span of years, it’s understandable to be overwhelmed. Still, technology is here to make our lives easier, and change should be welcomed with open arms. With that being said, we have reached our final destination, which is, fittingly, automatic deliveries.

Source: Unsplash

By 2028 and beyond, delivery as we know it, will change. Through innovative projects like Amazon’s drone initiative and self-driving Uber, automated home delivery is quickly becoming a reality. In 2016, self-driving startup Otto, acquired by Uber, successfully traveled 120 miles to deliver 2,000 cases of beer, marking the first-ever commercial delivery via self-driving technology.

Even other alternatives like underground transport tubes, autonomous air taxis, crewless cargo ships, river shuttles, and sidewalk delivery robots are being researched, explored and seriously considered. Engineers worldwide are developing software, sensors, artificial intelligence, vehicle-to-vehicle communication (V2V), vehicle-to-infrastructure communication (V2I), and intelligent lockers & boxes to help pave the way for this future.

The Future is Now

We are amidst a technological revolution. So as the world rapidly advances toward this and other sustainable methods, packaging manufacturers and consumers will only benefit from efforts that will revolutionize everything from customer experience and manufacturing to shipping and environmental protection.

The future is now. Companies should anticipate and embrace the coming of new technology. Evolving alongside these innovations will only serve beneficial as you reap the rewards and stay ahead of the curve.