Table of Contents

Due to the growing demand for luxury goods and the increasing competition for niche markets, it’s a no-brainer that opting for luxury packaging is the right decision.

According to Dot Com Distribution, 61% of consumers say they are much more likely to purchase a luxury product again if it came in luxury packaging.

In any industry, custom boxes benefit your presentation and promotional needs by enhancing and adding value to your products and brand.

As such, a large portion of a business’ budget goes toward packaging solutions for products.

Custom boxes give brands a competitive edge on the shelf and in e-commerce because it plays into the consumer’s unboxing experience and the impression it makes on them.

But what if you do not have the budget to design and produce custom luxury packaging?

When the cost comes into the equation, it can be very disheartening – especially for smaller-sized businesses.

However, that does not mean luxury boxes are unattainable!

There are still many ways to create affordable luxury packaging boxes without using premium materials.

In this article, we hope to shed light on affordable luxury packaging solution options and how to create luxury boxes for your products in the most affordable way possible.

Project Preparation

Clear Specifications

You must first establish your product, estimate box measurements, estimate the quantity of custom packaging, and project objectives.

This is the most commonly required information when requesting a quotation for custom packaging.

The clearer your information, the quicker you’ll receive a quote!

If you’re looking for the most cost-effective option, a packaging specialist can determine what elements need to be changed, altered, or added based on your specifications.

Planning in Advance

As with all successful projects, producing high-quality packaging solutions requires prior planning to give yourself and your manufacturer ample time to work.

Make sure you have determined the following beforehand:

- A timeline

- Measurements

- Design specifications

- Shipping method

- Warehousing method

Rigid Luxury Packaging Boxes

With the initial planning finished, it’s time to look at your package choices.

Typically, for high-quality packages and luxury brands, rigid boxes are used.

However, rigid boxes are constructed by hand and require meticulous work from a highly skilled operations team for the best results, so prices tend to run high for this.

If you still choose this luxurious packaging solution, make sure you choose the right structure, material, and design specifications based on your timeline. The costs will depend on the structure and material of your box.

The More Affordable Alternative

Luckily, rigid boxes aren’t the only option for creating luxurious packaging!

Suppose you’re a small to medium-sized business looking for custom packaging and premium boxes with a smaller budget than your competitors. In that case, you don’t need to pay premium prices for luxury packaging boxes.

You can instead choose less costly materials, such as a folding carton.

Folding cartons offers an array of structural design option, printing capabilities, and finishing options. With this, you can customize your package’s style & structure while still guaranteed a lower price point than rigid box materials.

Not only are folding cartons more affordable, but they are also much more eco-friendly and can be stored and shipped flat for convenience.

You can even opt for water-based inks and coatings for easy recyclability!

More information about folding carton options

Calculating Your Budget

With an idea of your packaging options, the next step is calculating your budget.

This will shape the trajectory of your project.

Having a clearly outlined budget can help you finalize the scope of your project, know your limitations, and minimize delays in your design.

To understand where your budget should stand, include the following consideration:

- Material choice

- Design services

- Printing and finishing

- Shipping and logistics

Choosing Your Structural Design

This is where the fun part can commence with dieline making!

A dieline is a computer-designed 2D template for your box packaging. It includes a layout (including custom artwork) of the final physical box.

This template communicates essential information for producing box samples and your final product.

If your structure is simple & effective, you won’t need to pay extra service fees for custom structural design services.

Thankfully, several manufacturers, like PakFactory, can reimburse you for this service when you work with them, so let’s dive into your style options!

Types of Luxury Packaging Styles

Choosing the right box structure for your luxury packaging is crucial in communicating a high-end feel for your products and brand.

If you have the budget to opt for a rigid box, there are a variety of structural styles you can choose from, including:

Magnetic/Hinged – Made from substantial greyboard material, the sound and feel of the magnetic hinged lid closure elicit an impression of luxury.

Two Piece – This is the box style used for the iPhone. They are premium boxes with a lid held together by friction. These boxes are also typically cost-effective due to their minimal & standard structure.

Drawer Style – This box slides out to present the product within and is famous for its appealing look, standing out on shelves.

Collapsible – A collapsible box can have the same elements as a magnetic box but can also be folded flat, making shipping less expensive and easier.

Alternatively, folding cartons offer an array of structural styles and are the inexpensive yet high-quality option we recommend.

Is your product fragile? Does it need a protective insert?

A great and popular option, that pairs well with a rigid box, is foam inserts.

You will need to spend a little extra for these add-ons, but they make a big difference in protecting your product from costly damages.

Measuring Box Dimensions

Once you’ve picked your custom packaging style, it’s time to determine the dimensions of your box.

You’ll want to base your calculations on internal dimensions.

Unlike the external dimensions, calculating internal dimensions helps ensure a snug fit for your product.

To keep costs low, try to make your box dimensions as small as possible while ensuring enough space to fit your products.

The Smaller the Box, the Better!

Smaller custom boxes cost less to produce and ship while also ensuring your product does not shift around during transportation, lessening the likelihood o damage.

Your customers will not be happy receiving a damaged product, so make sure your box dimensions are minimal and leave no room for damage but all the room for a great customer experience.

Focusing on Artwork Design

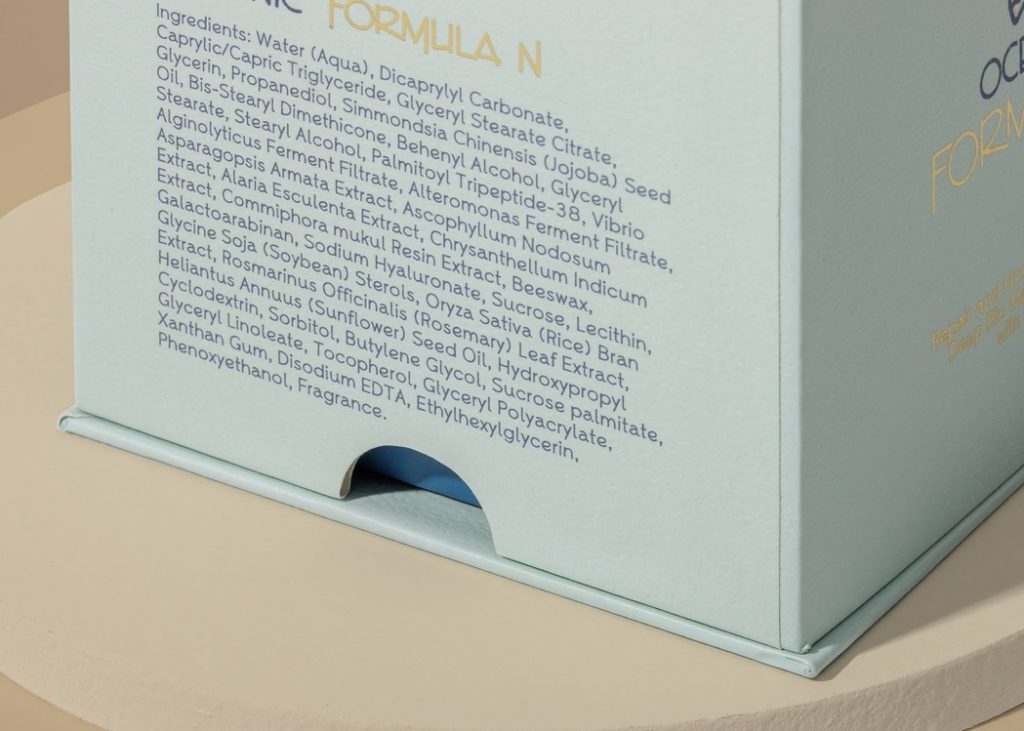

If you’re looking to make your packaging look more like premium boxes without spending too much, the artwork is where you want to focus your efforts.

Regardless of what color you use for your premium boxes (unless you are using PMS Colors) or the style of the artwork. Your budget will remain relatively the same.

Focus on the senses and emotions of your customers when it comes to your premium quality boxes.

A Luxurious Packaging Experience

Consider a minimalist option, as many luxury brands choose this route to create a visual heir of sophistication and class for their brand and products.

Including texture can also make your box feel more luxurious.

Including an embossed/debossed feature or another tactile element further engages the customers’ senses and creates a tailored experience.

Give your box crisp folds to prevent paper cuts and enhance functionality. Poor box structure can kill anticipation, so make the design pain-free and simple.

Use sound to your advantage too!

Rigid box styles can all elicit the perfect unboxing sound with proper design.

An element like a magnetic closure for your rigid box won’t break the bank!

Personalize luxury boxes. Anybody can provide a package, but the great ones offer a unique unboxing experience.

Put a personalized handwritten thank you message and special promotional card for specific customers.

Adding or combining any of these elements boosts the unboxing experience and encourages customers to repurchase from your brand.

Including these low-cost components in your box design will impress customers and create opportunities for developing a loyal customer base.

Luxury Packaging Design Tips

But if you’re still unsure of how to design your box, here are several tips for your design:

Suspense – Design your box to create anticipation from the moment your customer lays their eyes on your product. Entice them, but don’t overload them all at once.

Prestige branding – Less is more. Minimalism is luxury.

Exercise restraint with your design. Consider clean, understated elements over extravagant logos and excessive visuals.

Work with light – Light interaction with your box design is also crucial.

Use contrasting finishes and coatings to provide an attractive look in any lighting.

The above are just a few tips to get you started. Deeply think about your finishing options and how they will look in person to determine the perfect laminates or coatings for your design!

The Right Finish

The last step to consider when designing your box is the finish. Think of this step as the cherry on top.

The finish affects the final appearance while providing a level of protection and appeal.

There are many finishing options you can use to create the luxury look for your box, but for the sake of keeping costs low, let’s take a look at the two most popular laminates used:

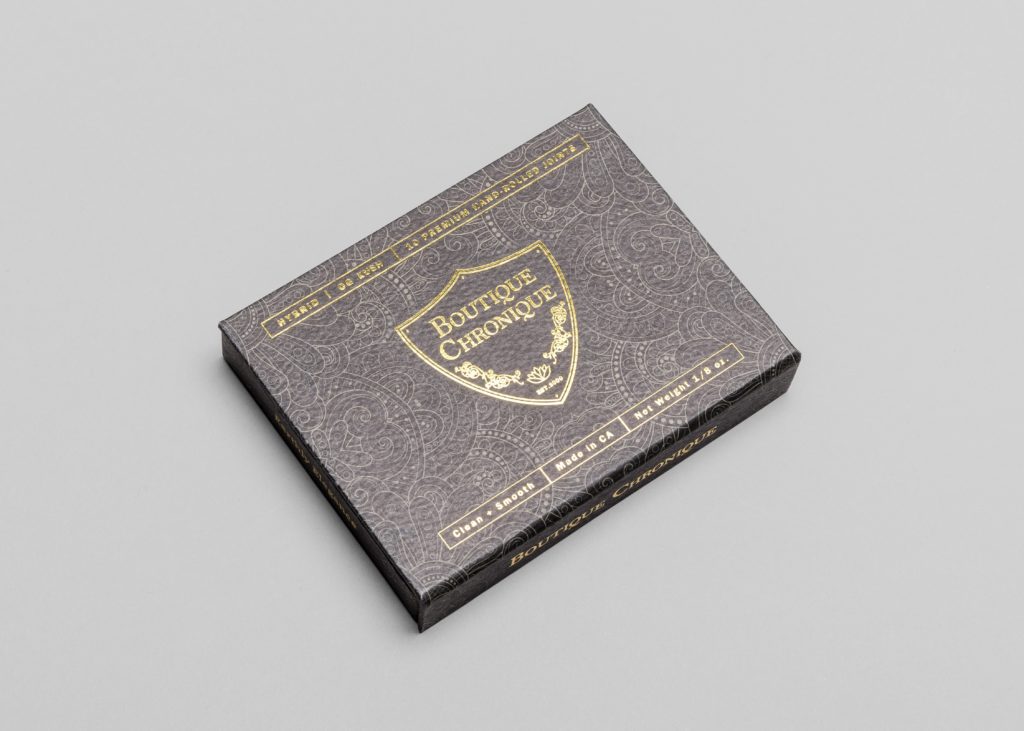

Matte Lamination – This is the most popular finish because of its luxe and simplistic appearance.

This finish is considered the “fashionable” and elegant finish compared to the rest and is also best for special printing options such as Spot UV, embossing/debossing, and foil stamping.

Gloss Lamination – This finish provides outstanding vibrancy to packaging boxes and instantly grabs a potential customer’s attention. It repels dust, dirt, and fingerprints and enhances the colors of your artwork designs, making the packaging super durable.

Textured paper is also widely used with this type of packaging but is typically the least popular for small to medium-sized businesses due to the cost.

Additional Special Printing Options

Adding special finishing provides an eye-catching, impactful look to any box and enhances the branding.

Spot UV –seals in color, producing an appealing sheen to dedicated sections, and protecting the surface.

Embossing/Debossing – Adds a raised or depressed imprint of a design or text, adding visual appeal and complexity.

Foil Stamping – Works best on smooth surfaces. It applies a thin coat of gold or silver foil to the box’s surface.

Adding extra embellishments are surprisingly less costly than you would think with large quantity orders and adds a luxurious look to complete your packaging design.

The Importance of Sampling Custom Boxes

When initially designing your packaging — especially if you are ordering a large quantity — it’s crucial to inspect the box to ensure you are happy with its functionality, design and artwork positioning.

The manufacturer typically handles all the required testing and proofs, but having a physical sample will help you find any hidden mistakes that might not appear otherwise.

If any changes are needed, prototyping prevents you from mass-producing premium boxes and paying the associated costs on the packaging you aren’t 100% satisfied with.

Read more on why getting a box sample is important for your packaging.

Working with the Right Manufacturer

Never settle in this department.

When producing premium-level packaging, it is crucial you collaborate with packaging experts that can guide you through every step of the process.

Look for a manufacturer that can provide the best cost-reduction recommendation for your project and assist you from ideation to fulfillment.

Learn how to choose the right custom packaging company for your project.

At the end of the day, all these elements should drive a singular purpose — to provide an unparalleled, luxurious unboxing experience at a fraction of the cost.

But that doesn’t mean you have to use costly materials!

Folding cartons allow for opportunities to create high-quality packaging through structural and artwork designs for a fraction of the manufacturing price of rigid boxes.

Regardless of what option you choose, your opportunity to create luxury packaging at an affordable rate starts here.

With the help of dedicated packaging experts at PakFactory, you can create cost-effective premium packaging that will leave a lasting impression on your customers.