Table of Contents

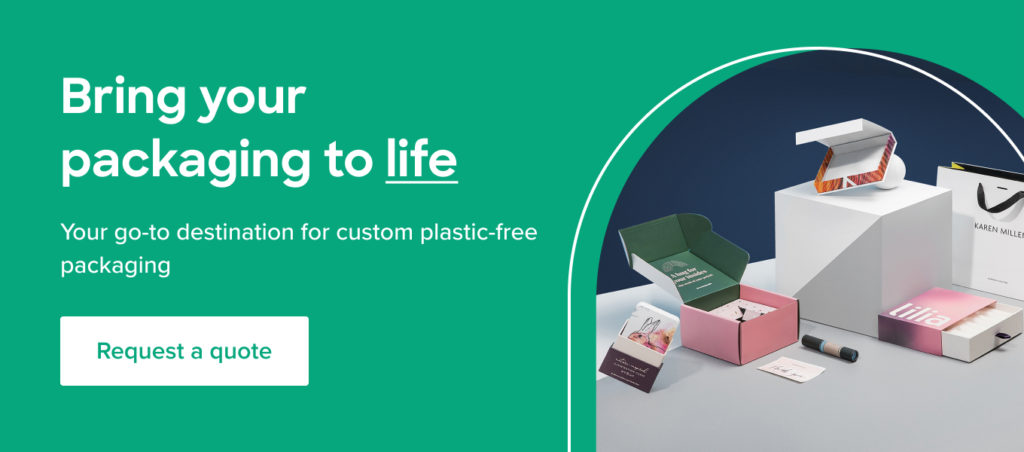

Paperboard folding cartons have been the most popular packaging options throughout history and remain one of the most popular today.

In the wake of eco-awareness, many businesses have chosen to opt for paper packaging to serve consumer demands in more sustainable solutions.

Folding cartons are not only cost-effective and versatile but also serve as a great packaging alternative to plastic.

Popular for being exceptionally lightweight and flexible, paperboard boxes can be used for nearly any type of product.

You’ve likely come across a folding carton box this morning when you had your cereal!

Let’s dive into the world of paperboard, their benefits and how different industries use them!

Paperboard: An Overview

History

The folding carton box marks an important time point in history because it was one of the first packaging types to gain popularity.

It’s been in use since the 1800s and has steadily gained popularity due to the ease of procuring raw material and quick production.

In its earlier days, paperboard was stuck together by strings and tacks to create the packaging.

Originally made by hand, folding carton manufacturing has evolved a great deal since.

Let’s discuss the process of creating folding carton boxes today in a bit more depth!

Process

Generally, folding carton boxes are constructed from paperboard (i.e., pulp from scrap paper) and reprocessed to create the packaging.

The paperboard undergoes a cutting, folding, and lamination process and is delivered laying flat, ready for construction and packaging.

More specifically, folding carton manufacturers that process the paperboard will prepare dielines to add artwork designs to, so they can be printed on large sheets of paperboard to be cut and scored.

This essentially means cutting the rolls of paperboard into flat sheets that will be fed into a printing press. Any images or artwork are printed onto the sheets at this point.

After printing and any other post-press processes, the paperboard sheets are cut, folded, and glued together to create your optimal packaging.

Depending on the packaged products, folding cartons will go through further structural engineering and quality control processes to ensure the product is held adequately within the packaging.

The Benefits of Folding Carton

Folding carton boxes offer many benefits, which is why they have consistently been used for packaging throughout the years.

Retail Friendly

One of the main advantages of using folding carton boxes is that these are great for retail shelves.

You can create premium packaging with custom folding carton boxes and really capture consumer attention.

The durable nature of folding carton boxes makes them suitable for retail since they are less likely to be damaged during transport than other packaging types.

Furthermore, through its versatility in printing, finishing and design process capabilities, folding cartons look great on display and allow for a high end feel as well as successful brand differentiation.

Environmentally Friendly

The materials used to manufacture folding carton such as Kraft make it an excellent option if you’re searching for environmentally-friendly packaging material that is still affordable and looks good.

The process of creating Kraft, as well as the recyclable nature of folding carton boxes, make it a great sustainable packaging choice.

The use of sustainable inks and coatings, such as aqueous coating, allows for fully sustainable product packaging that falls directly in line with your eco-conscious shoppers!

Versatility in Printing and Finishing

When it comes to making your product stand out, folding carton boxes can elevate it without compromising quality.

They are comparatively less bulky than other packaging types, and you have a lot of options when it comes to high-quality printing and finishing.

Custom packaging providers can help you identify and choose the perfect design and finishing to ensure that your folding carton box stands out and offers a high end customer experience.

Cost Efficiency

The other reason folding cartons are such a popular choice is because of its cost efficiency while still offering a high-end feel.

They are a very affordable packaging option, especially when evaluated against all the benefits they provide.

Folding cartons are a relatively low-cost option if you’re looking for high-quality, sustainable packaging solutions.

It’s because of these benefits (and many more!) that folding carton boxes are used for packaging across different industries.

Folding Carton Paper Grades

Folding carton boxes are available in a variety of different paper grades, each offering different capabilities.

You may be thinking, it’s just paper, how difficult can it be?

Well, each paper grade features different capabilities in printing and finishing and ultimately goes through different processes to accommodate your product and branding.

Understanding what you need from your paperboard box to create your ideal packaging is important.

Solid Bleached Sulfate (SBS)

Solid bleached sulfate (SBS) is a premium-grade paperboard option that is exceptionally tear-resistant.

It consists of 20% recycled materials and 80% freshly harvested wood chips which are chemically processed and bleached.

SBS paperboard comes in brilliant white color and is coated with a thin layer of naturally occurring clay to create a smooth surface for printing and special finishes.

These paper grades offer an optimal surface for;

- Design elements

- High-quality printing

- Finishes

- Coatings

Solid Unbleached Sulfate (SUS) Paperboard

Solid unbleached sulfate (SUS) paperboard goes through the same process as SBS, but differs in color, as SUS does not go through a bleaching process.

SUS paperboard is available in a brown color and is coated to create a smoother surface for printing.

The brown color of the material may alter the printing output to appear more muted or faded.

This paper grade is exceptionally successful in communicating sustainable brand initiatives thanks to the color and recyclability of the material.

Paperboard Printing and Coating Options

This is when branding comes into play.

As briefly touched on, the paper grade and coating play an important role in the printing of your packaging design.

White paper grades will offer an optimal surface for accurate color output as colors can be easily matched using the Pantone color matching system during the design process.

However, natural brown kraft paper can be more tricky to print on as the color of the paper grade may alter the printing output completely.

As briefly discussed, colors may appear more muted and faded. Therefore, the end result may be difficult to see or read, if there is any text.

The best way to print on kraft folding cartons is to lay out your design in white ink before printing your final design to ensure optimal color output.

Paperboard can benefit from both offset and digital printing thanks to its versatile nature.

Offset printing is recommended for its high-quality output. This is especially important for very intricate designs that need crisp lines.

Digital printing is recommended for simple designs that don’t necessarily need much definition to be memorable.

Coatings can also be added to folding cartons to accommodate certain industries more effectively.

For example, the food and restaurant industry usually requires wax coating to avoid leaking and grease markings on their final packaging.

Furthermore, Aqueous coatings can be used to not only establish environmentally-friendly initiatives, but can also be used on the interior of food packaging without adding any harmful or toxic chemicals.

Thanks to the versatility of folding carton, it can also endure unique and special finishes that add to your branding including:

- Embossing/debossing

- Spot UV printing

- Foil stamping

Design Elements to Consider

The great thing about paperboard is its cost efficiency, you’re able to splurge on design elements that elevate your brand identity beyond your expectations.

While printing capabilities are highly versatile for this packaging material, it’s worth noting the endless design elements paperboard is able to take on as well.

Embossing & Debossing

Embossing & Debossing is a process that presses images, designs, and texts into materials to create a raised or depressed image of your artwork.

This is exceptionally impactful for things like;

- Logos

- Certifications

- Artwork

Spot UV Printing

UV printing applies a varnish to the material and cures it using ultraviolet (UV) light.

This coating targets specific areas/spots of the printed product to seal their color in, produce an attractive sheen, and protect the surface against moisture and other types of wear and tear.

The use of a spot finish also creates a diversity of textures on a printed surface for a dramatic, eye-catching effect.

Spot UV is one of the many specialty printing techniques used to produce impactful packaging to differentiate brands/products from each other.

Like lamination, it increases the perceived quality of printed items. Note that spot UV ‘printing’ is a misnomer, as it is a coating technique as opposed to a printing method.

Paperboard across Industries

You’ll likely find paperboard packaging in almost every industry you can think of.

Some of the industries using paperboard packaging include;

- Cosmetics industry for both makeup and skincare

- Food and beverage, such as cereal boxes and other containers

- Cannabis industry, for CBD oils

- Pharmaceuticals for secondary packaging

We’ll look at some of these industries more in-depth to get a better idea of how paperboard packaging manufacturers handle requests:

A pharmaceutical use for paperboard boxes

In this case study, high volumes of folding cartons were needed to transport medication to Africa.

The folding carton types needed to be integrated into the company’s existing automated folding process.

The manufacturer was able to fulfill the order by closely studying the engineering behind the company’s automation process and design packaging accordingly so that it could be packed at the desired speed.

All in all, this folding carton packaging was a success in packaging pharmaceuticals for a great cause!

Sensitiva: The Power of Alternative Health & Wellness

Sensitiva’s goal was to use sustainable packaging materials that communicated their brand values across products of varying sizes.

To achieve this, folding carton boxes with anti-scratch matte finishes were used to create packaging for a variety of products.

Multiple artwork styles were printed together in a single production with folding cartons, thereby making it more time and cost efficient.

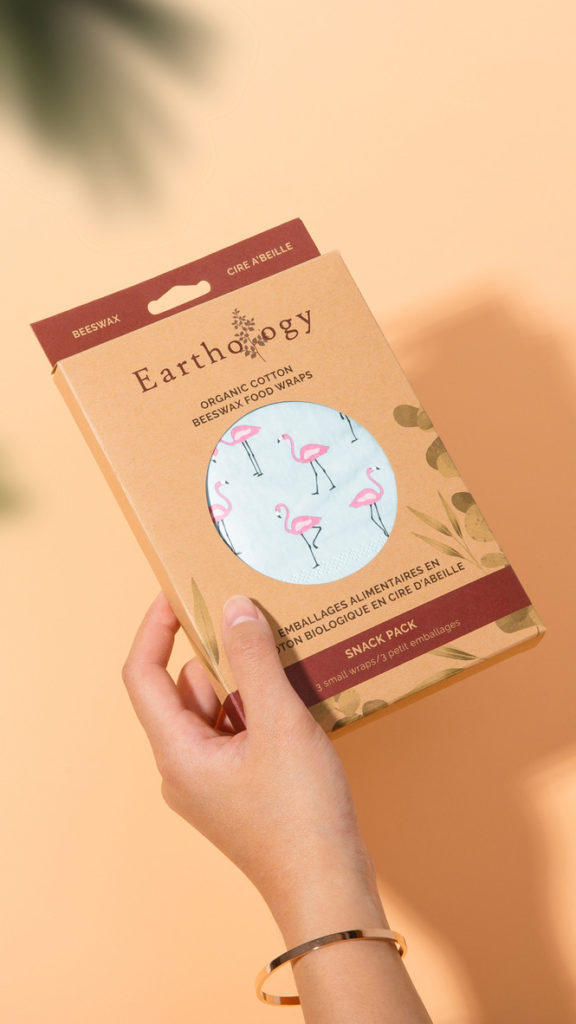

Paperboard with Windows

This project aimed to design folding carton packaging where a customer could see the product before purchasing, also known as window patching!

It also needed to include high-quality prints on the packaging to explain its features and benefits.

Using windows in the package design secured with additional reinforcements was the strategy used.

This allowed customers to see the product while still keeping it secure within the packaging.

Furthermore, the product became the main attraction which was very beneficial in this case!

Folding cartons are a great packaging option across a versatile range of industries.

With it’s endless printing and finishing capabilities a high end customer experience can be achieved while establishing a strong brand narrative throughout.

At the end of the day, your packaging speaks for your brand and products.

Folding cartons are a cost efficient way to do so effectively, regardless of the industry your business runs in!

Get in contact with our product specialists today for guidance and support on your first project!