Table of Contents

Emboss vs Deboss

What does it mean to emboss paper? What about deboss? If you have these questions, you’ve come to the right place!

Embossing paper and debossing paper are like two sides of the same coin.

They are popular finishing processes that press images, designs, and texts into paper and other materials but are different in that they are opposites.

Embossing paper creates raised silhouettes of your artwork design on a piece of material while debossing leaves a deep impression.

Both processes have a wide range of applications, including:

- Brochures

- Postcards

- Business cards

- Letterheads

- Certificates

- Folders

- Packaging (of course)

Paper embossing creates visual complexity by adding a new dimension to your brand messages and graphics by enhancing your logo, text or artwork designs.

The Benefits of Embossing and Debossing

Embossing and debossing are two popular design techniques used in packaging that can provide a variety of benefits.

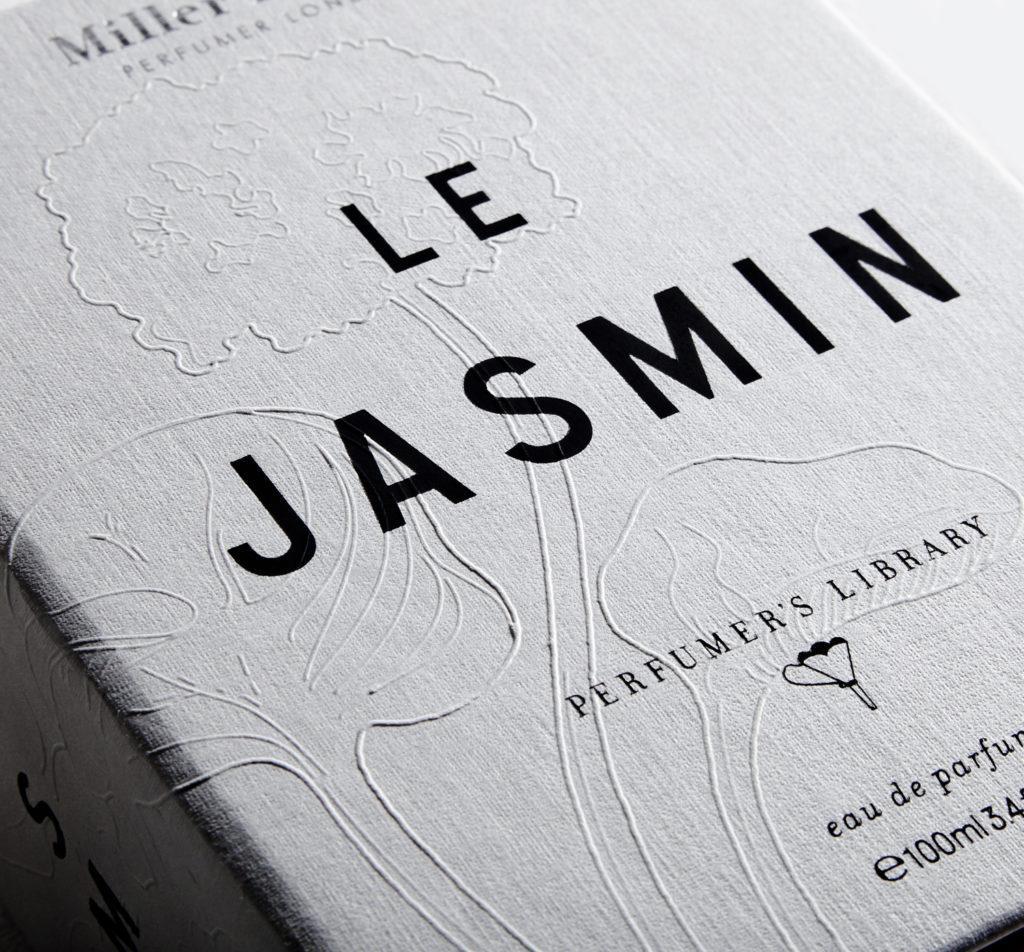

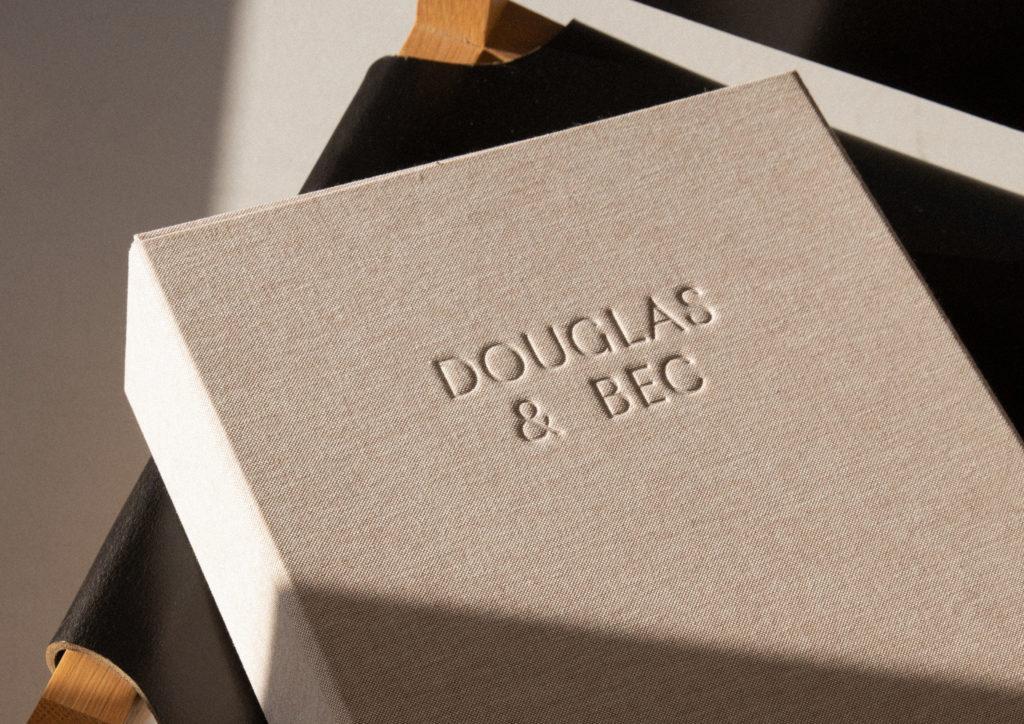

Firstly, these techniques add a sense of sophistication and luxury to the packaging, making it stand out on the shelves and catch the eye of potential customers through an embossed image or text.

Secondly, they create a tactile experience for customers, making the product more memorable and appealing.

In addition, embossing and debossing can highlight essential information, such as branding or product features, which can help the customer make informed purchasing decisions.

These techniques are also highly durable, making them resistant to wear and tear, ensuring that the packaging maintains its visual appeal over time.

Overall, embossing and debossing are essential to design strategies that can provide significant advantages to any packaging design project.

Die Types and Styles of Embossing/Debossing

Paper embossing can incorporate several die types and styles to achieve unique effects.

But before we get into that, let us briefly look at the three most common metals used for embossing and debossing dies: magnesium, copper and brass.

Magnesium is only usable for single-level die types and is the cheapest but softest metal. This metal is susceptible to quick wear and damage should it jam on the stamping press.

Copper, like magnesium, is only used for single-level dies but is sturdier and more expensive.

Brass is required for multi-level and sculpted die types. It is the hardest metal of the common dies and will last very long, but it is two to three times more expensive than copper.

What Are The Die Types?

Now that you know the common metal plates used for dies, we can dive into the different die types to emboss paper.

Detailed dies can create more intricacy and depth to take the visual interest of your design to the next level, but depending on your needs, many options are available to you:

Single-Level – As the name suggests, this die type changes the material’s service at one level. It is the most common and cheapest method.

Multi level Emboss– A die type that features several distinct levels.

Bevel-edge – Similar to a single-level die, but with a 30 to 60-degree angle on the design’s edge. Deeper dies need a bevelled edge to prevent cutting the material.

Chisel – Frequently used for debossing, this die has a distinct “roof” shape or v-shape.

Textured – A single-level die with etched texture. This die type works best with artwork that does not require details to look refined.

Rounded – A die type that produces rounded corners commonly used for logos and typographic elements.

Sculptured – The most expensive die type. It requires a hand-made custom sculpt from a provided reference for the stamped image or embossed pattern.

Embossed Paper and Debossed Paper Styles

Not only are there many different die options, but there are also several styles of embossing/debossing to choose from too! These styles include:

Blind Embossing – The blind emboss style does not use ink or foil stamping. It provides a distinct and clean design that is best for subtle looks on embossed paper.

Registered Emboss – This style uses ink, foil stamping or another embossed effect to create more dimension and a shiny or polished appearance to your design.

Combination Embossing – This style incorporates foil stamping and blind embossing for a. It is often used to highlight key details of a design, such as logos, slogans, or graphics. The design is embossed and lined with foil to create an impactful 3D design.

The Embossing and Debossing Process

With the styles and types of die out of the way, it’s time to look at the machining process.

Thankfully, using an embossing machine is reasonably straightforward.

A male die with the embossed image is placed underneath the material, while another female die is positioned above it.

The machine then presses the male and female die together to stamp the design onto your material for an embossed image.

Why is Embossing and Debossing Used?

This technique works exceptionally well for heavier stocks like corrugated boxes and rigid setup boxes.

And as mentioned earlier, adding foil stamping to the embossing process is also possible and enhances the visual intensity of the printed piece through heat embossing.

Foils such as gold and silver are common choices for heat embossing, but solid colors work just as well and can enhance your product’s visual quotient.

Why Use Embossing and Debossing?

Finally, you may wonder why you should use the embossing process on your product. What is embossing/debossing’s benefit to your brand?

Well, it creates a memorable experience for your customers. The details literally pop out to customers and command their attention.

Embossing/debossing differentiates your brand and provides an excellent ROI, as it can significantly increase your product’s visual impression and perceived value without costing too much.

Overall, using finishing techniques like embossing or debossing is an easy way to elevate your branding and progress your packaging design to the next level!