Table of Contents

An Overview of Foil Stamping

Foil stamping is a specialty printing process that uses metal dies, heat and pressure, to apply foil films.

Foil stamping has a wide range of applications, including;

- Stationery

- Labels

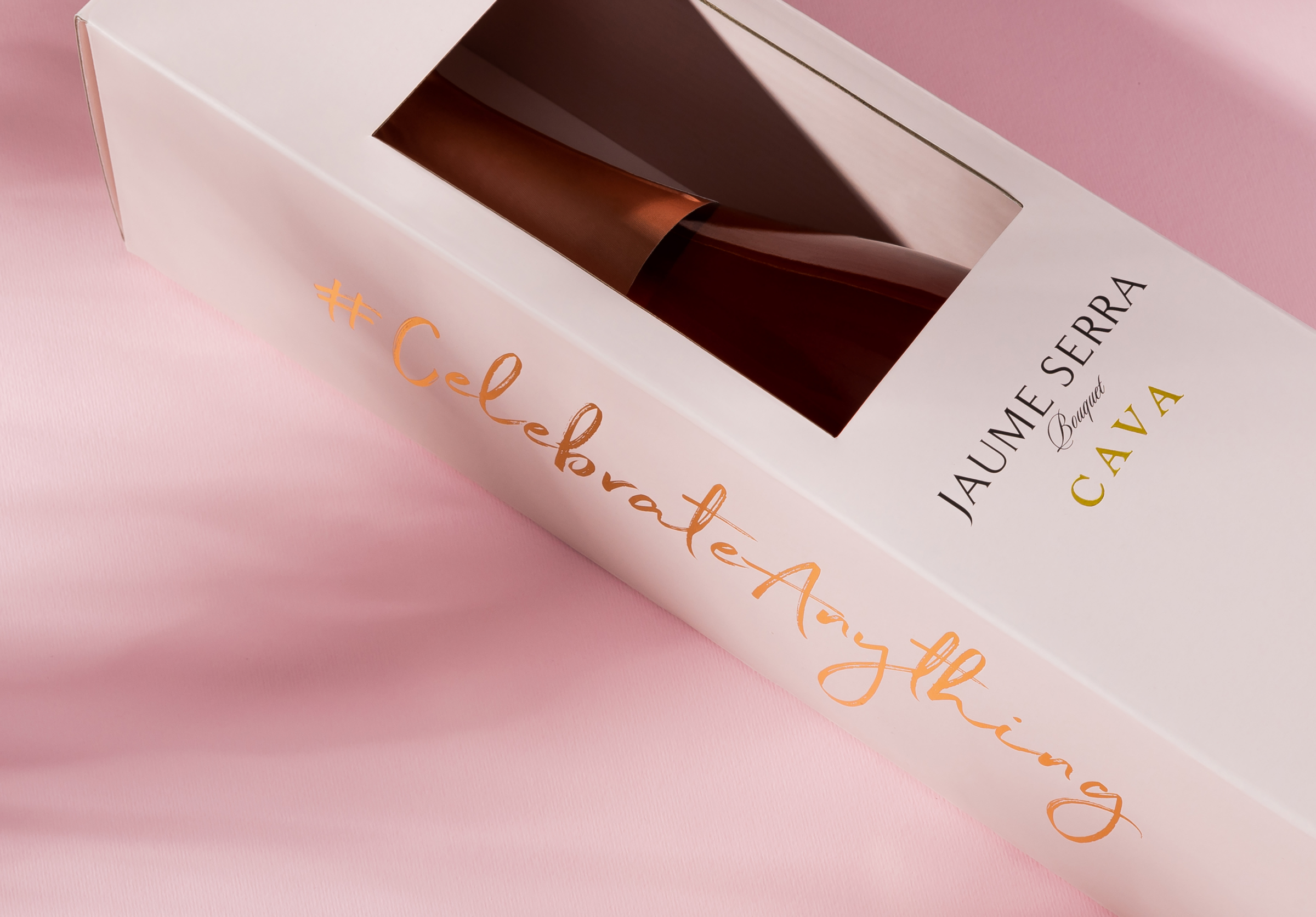

- Product packaging

- Holiday cards

- Seals

- Pocket folders

- Postcards

- Certificates

Source: PakFactory

The modern technique, known as hot stamping, was first conceived in the late 19th century.

Today, it is leveraged to create visual interest and increase the perceived value of products.

A foil is a thin film coated with the colors that are applied to a product through a process known as hot stamping.

The pigment is placed on a clear film, which acts as a carrier that transfers the color onto the product.

Another layer of the foil consists of pigmented sediments, and a third layer is a heat-activated adhesive that sticks the sediments onto the product.

Like Embossing & Spot UV, you can apply foil stamping to all kinds of paper stocks.

It works best for stock with a smooth, even surface as opposed to textured or lined materials.

Types of Foil Stamping

Based on your substrate and the type of finish you want, you can choose from one of the four hot stamping techniques discussed below:

- Flat foil stamping, a simple, economical process where a copper or magnesium metal stamp transfers the foil onto the substrate. It achieves a foil design that relatively raises from the surface.

- Vertical foil stamping, which stamps foil designs on flat substrates and cylindrical shaped areas.

- Sculpted foil stamping, which uses brass dies to achieve a raised image for a clearly defined and carved look.

- Peripheral foil stamping, where foil heat transfers are applied to the outer perimeter – across the entire circumference – of the product.

Source: Sonhab Chocolate – PakFactory

Typically gold and silver coloring is used to create a luxurious effect.

Various finishes, such as glossy, matte, metallic, holographic sparkles and wood grains are available.

Types of Foils Used

There are different types of foils that can help create distinctive packaging/products in line with your marketing campaign or brand image.

Metallic foil, which offers an attractive patina across colors like silver, gold, blue, copper, red, and green.

Matte pigment foil, which has a muted appearance but an intense depth of color.

Gloss pigment foil, which combined high gloss with a non-metallic finish across a variety of colors.

Holographic foil, which transfers hologram images for a futuristic, eye-catching look.

Special effects foil, which can be used to create a range of textures, including mimicking the appearance of leather, pearl, or marble.

The Hot Stamping Process

Hot stamping is a machine-based process.

The foiling die on which your design is etched is heated and stamped with high pressure to bond a thin layer of foil to the substrate.

The application of heat and pressure is the core approach that delivers the desired result on the substrate.

The die can be made of brass, magnesium, or copper.

Though it is an expensive purchase, it offers multiple uses and is therefore worth the initial investment.

The Benefits of Foil Stamping

As foil stamping doesn’t use ink, the foil color is not impacted by the color of the substrate upon which the design is applied.

Foils in light and metallic colors can be easily used on darker colored papers.

You can achieve a range of finishes with hot stamping, allowing you to experiment with your branding and packaging.

The striking effect possible with this technique also makes it a good solution to stand out from the sea of competitor products.

For other print finishing options, you can check out: Embossing & Debossing, Spot UV, Window Patching & Soft Touch.

Foil stamping has great potential to elevate and breathe new life into existing packaging designs.

Whether it’s to add a little pizazz to your logo or enhance your artwork designs, foil stamping gives your products and brand a higher perceived value.

Working with a product specialist allows you to optimize your packaging in every aspect from structure to artwork.