Table of Contents

Are you considering a folding carton for your product packaging? If you are, you’ve come to the right place to learn everything you need to know about this option! These foldable paper boxes are a trendy and versatile choice for many industries. Though these boxes are commonly seen as a paper packaging option for food, it is viable for pharmaceuticals, cosmetics, and electronics.

Source: HRBLS by Pharmakon Supernatural – PakFactory

The paperboard material is excellent for customizing your package’s size, shape and structure to accommodate any product.

So in this article, we will delve deep into what makes a folding carton tick starting with its definition, the common materials used, styles available, production method, and some pros and cons of this type of packaging. By the end of this master guide, we hope to have provided you with sufficient knowledge to decide whether this paper carton packaging option suits your product.

What is a Folding Carton?

Before we take a closer look into this versatile packaging option, what exactly is it? Well, folding cartons are a type of paperboard packaging popular among consumer products for their low weight and versatility.

It is commonly used as secondary packaging, and as the name suggested, these foldable paper boxes are designed for easy assembly from a single flat sheet into a three-dimensional package, making them cost-effective to transport because they are shipped flat before being assembled while maintaining a high level of customizability.

Folding Cartons vs Rigid vs Corrugated

But what are the differences between the similar and equally popular packaging options of rigid and corrugated boxes? To get a better understanding of the key differences between each option, we’ve provided a simple chart below:

| Rigid Boxes | Folded Carton Boxes | Corrugated Boxes | |

|---|---|---|---|

| Set up | None if not foldable | Needed | Needed |

| Sturdiness | High | Low | High |

| Product Safety | High | High with the aid of inserts | High |

| Cost | Generally High | Depends on printing & finish | Depends on printing & finish |

| Appeal | Generally High | Depends on printing & finish | Depends on printing & finish |

| Reusable | Yes | Usually not | Yes |

Folding Carton Packaging Materials, Types & Styles

In terms of materials, the most common materials used for manufacturing standard folding cartons are paperboard made from wood pulp, a renewable and environmentally friendly resource. However, higher-grade, certified paperboard options that meet food and even medical standards are also available!

Alternatively, to increase eco-friendliness, kraft paperboard made from 100% post-consumer recycled material or reclaimed paper stock is also a popular option. And if you thought the material options offered a lot to consider, a wide selection of styles and different types of boxes are also available. In this master guide, we have provided you with the seven most popular options; let’s have a look!

The tuck end auto-lock bottom box, or crash bottom box, has a bottom design that automatically locks in place during assembly with a simple tuck flap. This box style is recommended for heavier products, like wine and beer, as it is the strongest among all paper box packaging options listed below.

Alternatively, the snap bottom or lock bottom box is another strong option suitable for heavier objects like wine or electronics. Also known as the 1-2-3 bottom box, this box style has flaps that push into each other and lock in place.

Straight tuck end boxes are stored flat and do not require additional assembly. They are identified by having both the top and bottom closures on the same side of the box and slits on the ends to keep the tucks locked. This style is ideal for light or medium-weight products like cosmetics or essential oils.

Reverse tuck end boxes are the same as straight tuck but have the end closures on the opposite sides of the box. Since they are nearly identical, reverse tuck boxes are also ideal for light or medium-weight products.

Paper sleeve packaging is a carton style designed to slip over another, typically undecorated box. This option is a very popular choice due to being the least expensive option and can instantly create fantastic customization for a plain box.

Double wall tray and lid boxes, or two-piece boxes are separated with a top and bottom half. The tray and lid fit snuggly together to create a sturdy double wall ideal for luxury products like jewelry and clothing or serve as food packaging for products like confectionery.

Customized folding carton boxes are the final popular option. Who said foldable cartons needed to be a certain way? Custom cutouts and inserts for the above options are limited only to the imagination. A well-placed cutout or insert can add a unique flare to your packaging, differentiating itself from competitors!

Whether using folding carton boxes as a paper food packaging solution or for other items like cosmetics and electronics, the styling options are limitless. From choosing kraft paper packaging for eco-friendliness or utilizing a two-piece box for added luxury, these foldable paper boxes are an excellent option for any product!

Manufacturing Processes

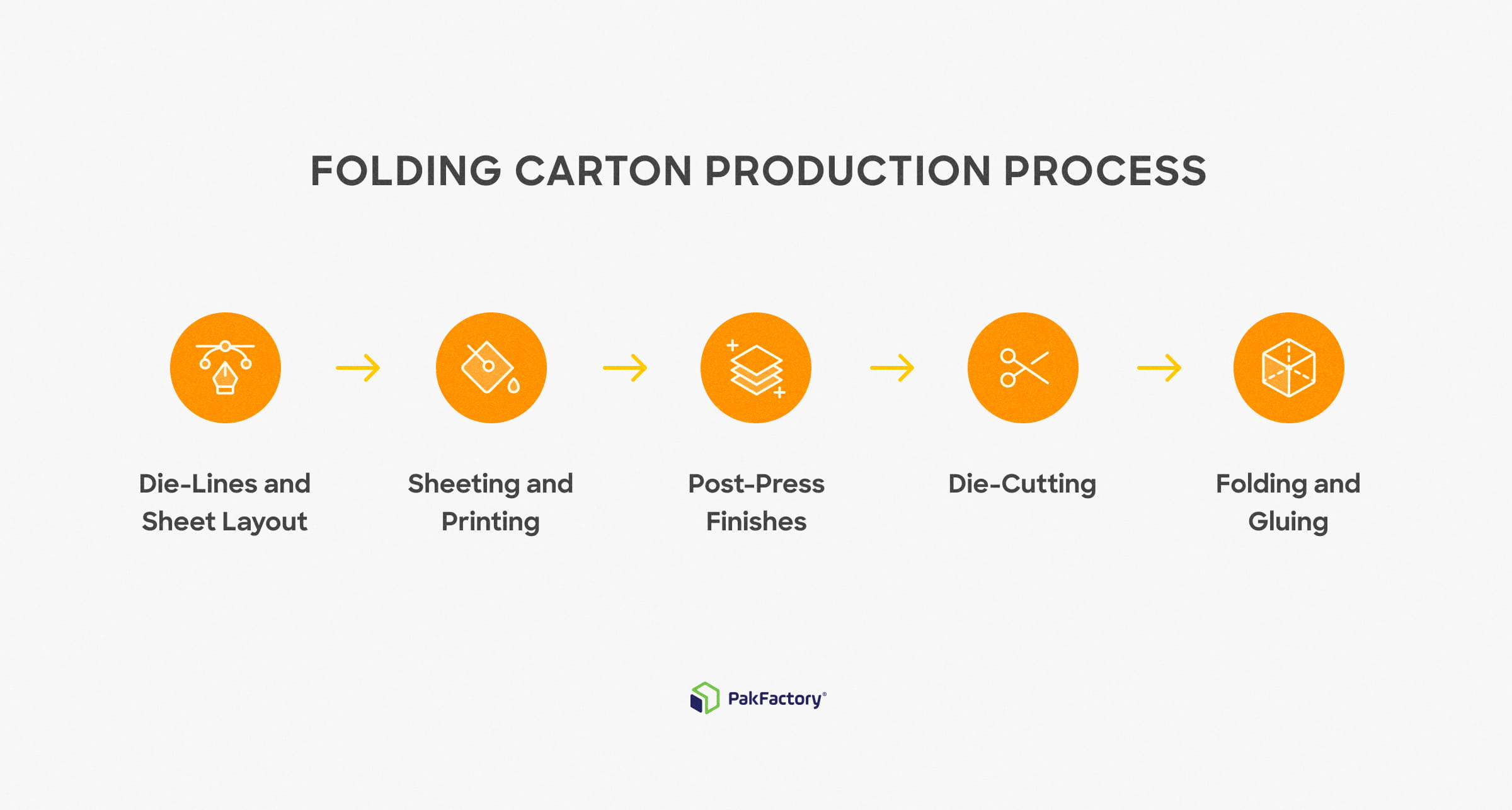

Regardless of the materials or style you choose for your carton packaging project, the process of making folding cartons remains the same. Once you’ve finalized your design choices for your box, it is time to let your packaging supplier get to work with the below list of elaborate processes known collectively as converting:

- Die-Lines and Sheet Layout: Die-lines are flat versions of the box showing what the final 3D box will look like. It shows the locations for die-cutting, folding and gluing while also showing the position of the artwork on the final package.

- Sheeting and Printing: Large rolls of paperboard must first be cut into sheets before running through the printing press. Manufacturers will ensure that the grain is running in the direction that will be most efficient and effective for this step. When the sheet enters the press, any imagery and artwork you designed will be inked and coated onto the sheet via offset, digital or flexographic printing.

- Post-Press Finishes: Further optional customizations like hot-foil stamping or embossing and debossing are done via specialized machines during this stage to enhance the look of your box.

- Die-Cutting: This stage is where many duplicates of your carton are cut from the paperboard sheet. The die is a specialized, elaborate cutter akin to a cookie cutter that will cut the paperboard while minimizing waste and allowing for easy folding where necessary. The manufacturer recycles excess scraps of paper made from this stage to form new paperboards.

- Folding and Gluing: The final stage of the converting process is where your box’s flat, die-cut pieces are fed through the machine for folding, pre-breaking and gluing. Some cartons that include transparent windows in the design are applied in-line during this stage. The manufacturer will aim to complete these processes in the fewest passes possible.

Pros & Cons of Folding Cartons

Now that we’ve gone over the intricate details of what makes a folding carton a popular and excellent choice for your packaging needs, what are the pros and cons of this option? Like the other popular options, there will always be benefits and downsides. Weighing these options is critical in deciding which packaging is best for you.

For starters, this packaging option can be cost-effective, sustainable and versatile. Carton boxes can come in many different shapes and sizes while being cheap to manufacture in large quantities. The materials used in this manufacturing process are also 100% recyclable, making them better for the environment.

Folding cartons also have a plethora of printing and unique finishing options available to choose from. As mentioned in this guide, printing options include offset, digital and flexographic printing, allowing excellent colors, unique textures and visual effects. For special finishes, this packaging option offers things such as:

- UV Coating

- Spot UV Coating

- Lamination

- Embossing/Debossing

- Die Cutting/Scoring

- Glitter/Pigment Sprinkles

- Foil Stamping

Even options for certified grades of paperboard material are available to accommodate food and medical industry standards!

But though these many benefits are heavily in favor of folding cartons, there are still a few minor disadvantages compared to other options. The strength and durability, for example, can be a disadvantage, but foldable cartons can still be solid and reliable with additional inserts. However, compared to the more sturdy rigid and corrugated boxes, they may not be as protective of the product inside.

Additionally, due to the limitations of cutting machinery, thickness is limited to 0.81 mm, which makes it difficult for this packaging option to hold significantly weighty products.

And though we did mention that folding cartons are sustainable, on the other hand, some packages tend to be challenging to assemble and are often improperly thrown away after a single use, increasing waste and counterbalancing the fact that this option should be eco-friendly.

Overall, this packaging option is excellent for many products, but always consider the pros and cons to ensure this option is right for you. That being said, what industries are these foldable boxes best for?

Suitable For Many, Best for Some

Source: PakFactory

The food and medical industries are the first thing that comes to mind when considering the industry that best suits foldable cartons. We mentioned earlier that this packaging option offers different grades of paperboard suitable to specific industry standards, and this is where that advantage shines through.

To learn more about paperboard grades, click here!

But to briefly summarize, with more expensive and highly durable paperboard grades available, like Solid Bleached Sulfate (SBS) and Folding Box Board (FBB), it’s no question why medical and food companies prefer the folding carton. Options such as various paper grades help protect sensitive products from dust and damage while keeping the product fresh longer.

Source: PakFactory

Other industries that greatly benefit from foldable box cartons include the cosmetics industry for its lightweight and attractive packaging designs and the electronic industry for its ability to protect from physical damage, dust and moisture.

But though these industries benefit the most from this packaging option, that doesn’t mean folding cartons are unsuitable for other products outside these industries!

Need help finding the right custom packaging for your industry? Browse here!

So Let’s Get Packing!

Even if you have a product outside of the industries mentioned above, the folding carton can still offer great benefits for your product. If you are still unsure if this packaging option is right for you or if you are ready to take the next step in your packaging project journey, contact one of our packaging specialists for more information!