Table of Contents

Measuring box size is relatively straightforward! However, for custom packaging, these measurements are crucial to your product’s safety. So even though box measurement is not rocket science, accurately measuring a box for a custom package requires a little more attention to detail.

Box dimensions are a critical part of any package as they significantly impact what materials are needed, the cost of production, and shipping and warehousing costs.

Think of it this way; minimal room for movement in a box means minimal room for damage and a reduction of your overall costs, so it is essential to get the measurements right!

To help you do that, we have laid out a clear step-by-step guide for finding and measuring dimensions, calculating the volume of a box, and one essential consideration to keep in mind to provide you with the most accurate measurements.

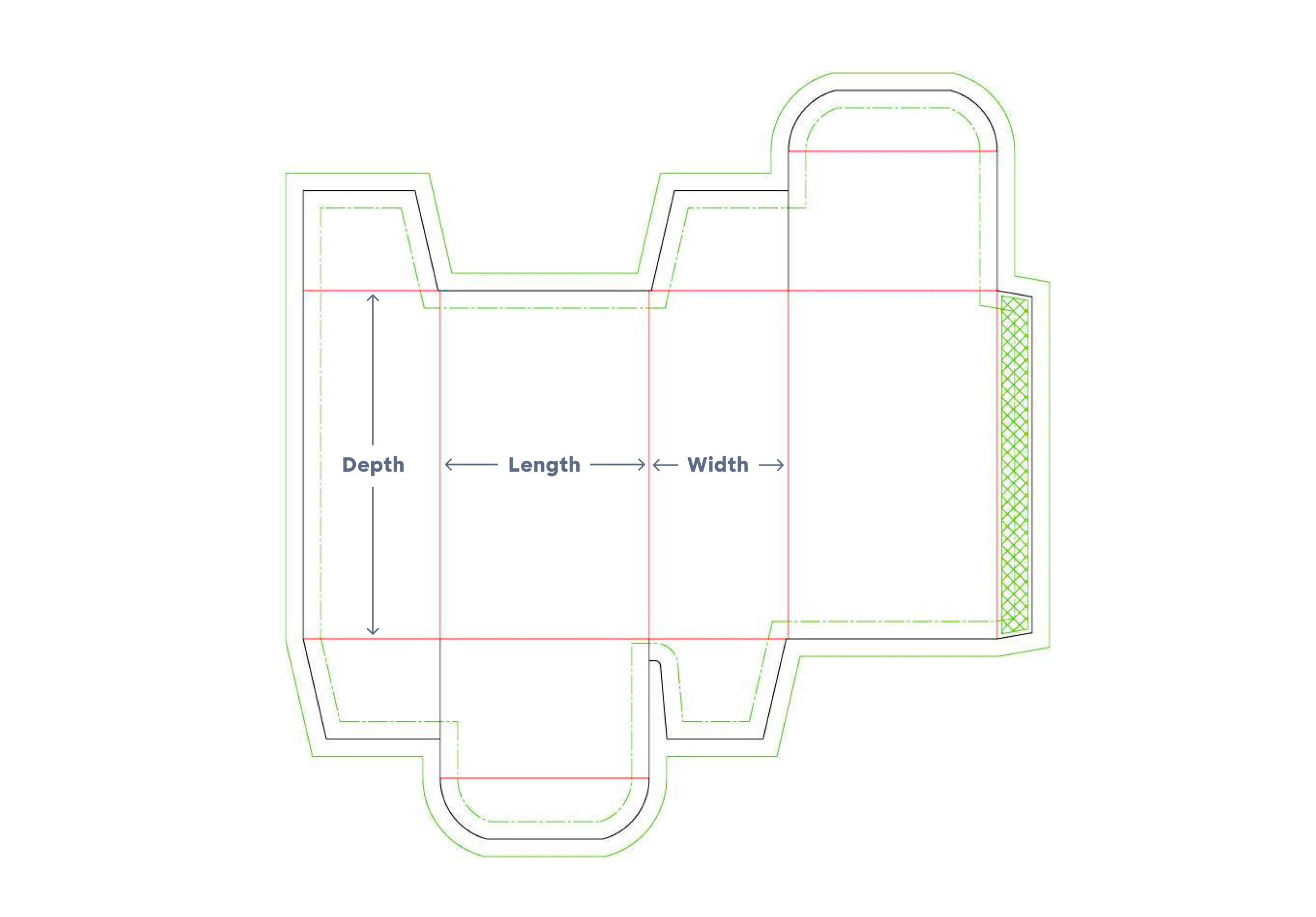

The Three Dimensions of a Box

The first step to creating perfect packaging is to measure the three dimensions inside your box, not outside — more on why you need to do this later — by using a ruler or tape measure and rounding each result to the nearest whole inch. But to do that, one must know the three dimensions: length, width, and depth.

Source: PakFactory

Keep in mind that different companies use depth and height interchangeably. However, the industry standard order of dimensions when recording or reading measurements remains the same: Length x Width x Depth (LxWxD) or Length x Width x Height (LxWxH).

- Length: The longest side when looking at the top of the box.

- Width: The shorter side when looking at the top of the box.

- Depth (Height): The side perpendicular to the length and width.

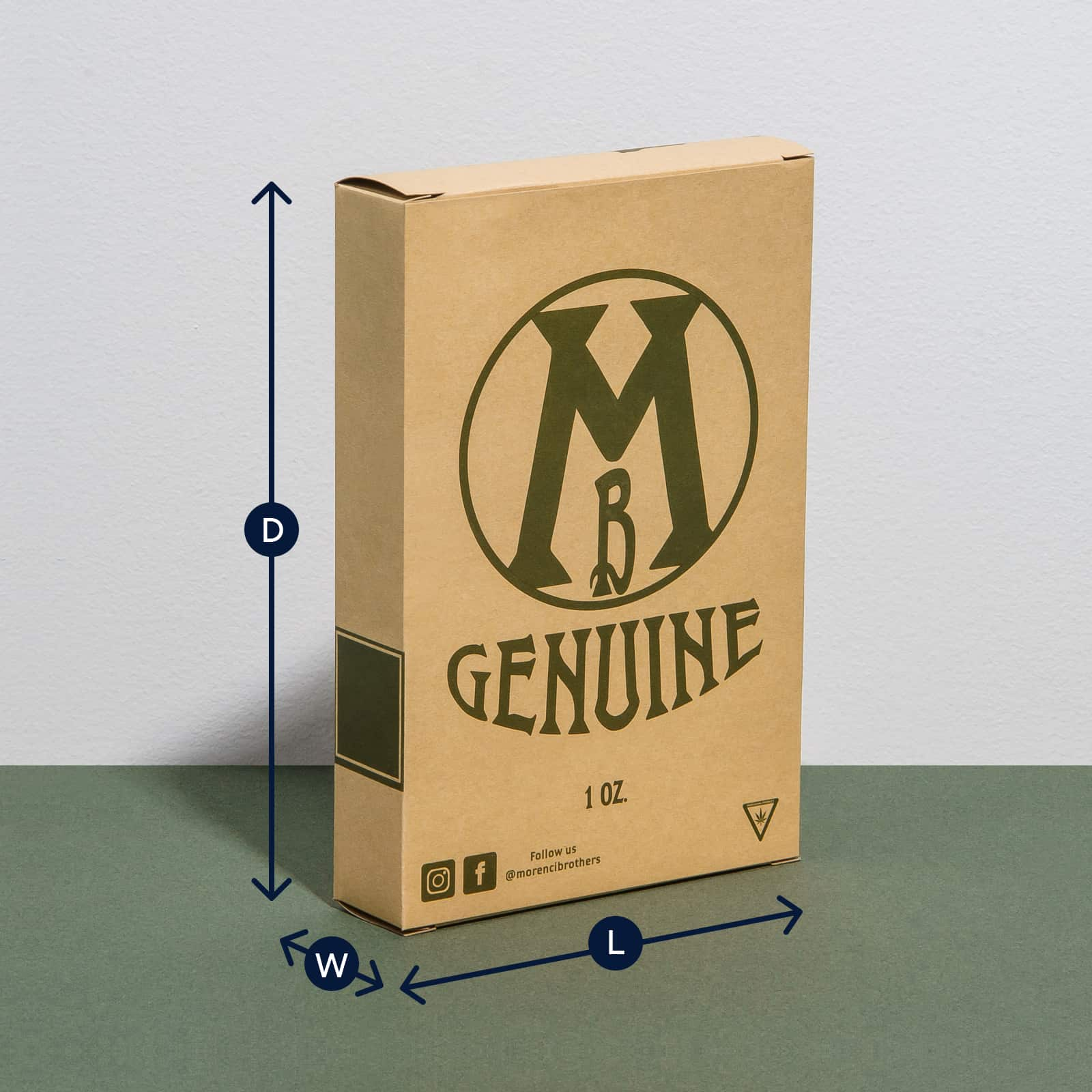

- In the case of a tall or upward-facing box, the depth will be the most prominent dimension, while the length and width will be smaller.

Source: PakFactory

- As seen below, the depth and width will be much smaller than the length of long boxes.

Source: PakFactory

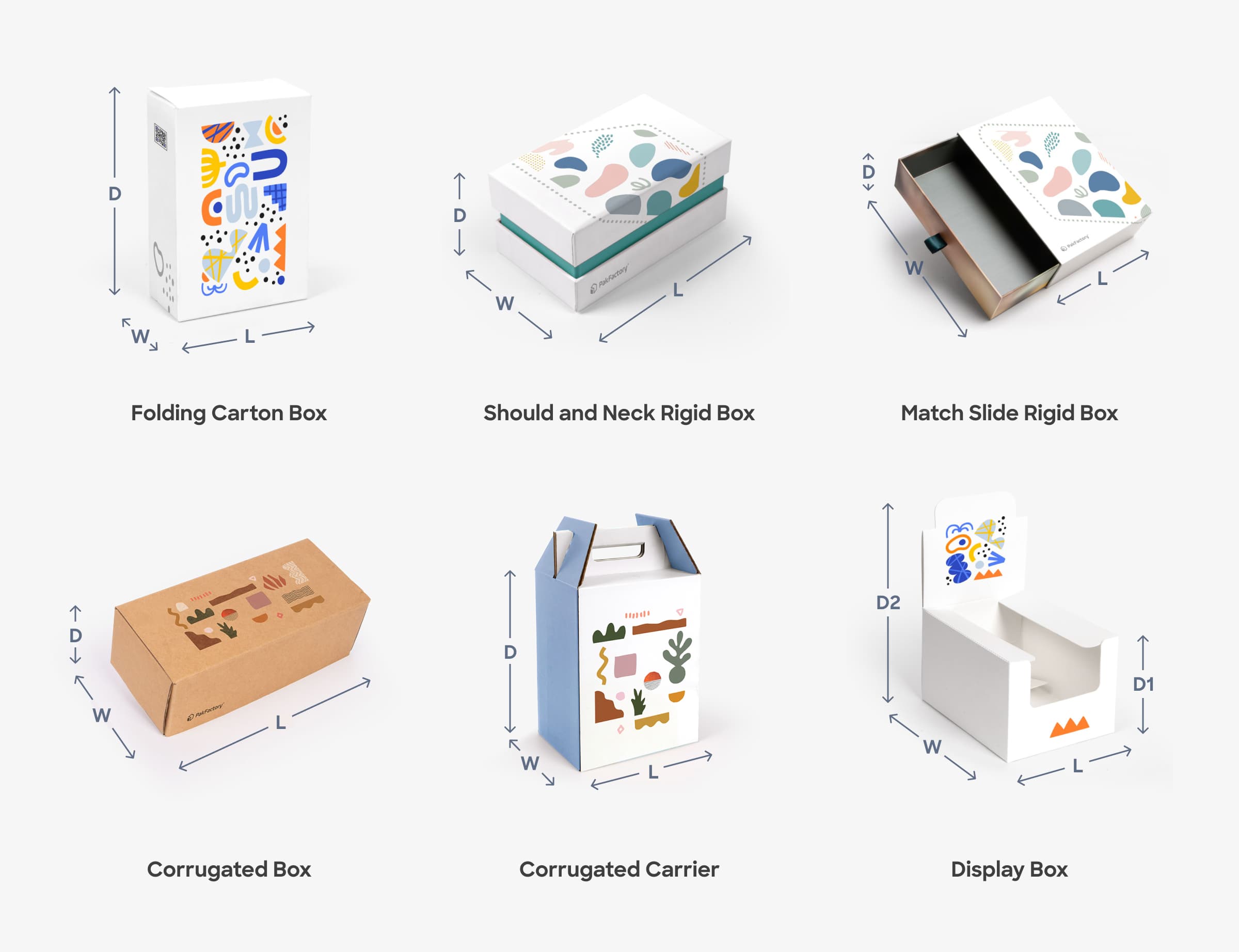

Regardless of your chosen package, you must always know the exact package dimensions before moving on to manufacturing. Below are a few additional examples of different box sizes and where to find their length, width and depth.

Source: PakFactory

Calculating the Volume of a Box

The next step after measuring your box’s length, width and depth is to calculate the volume to help determine how well your product will fit inside the package and give you a better idea for your shipping, warehousing and distribution processes.

Volume plays a crucial role in material optimization, cost reduction and the structural engineering of your packaging, so do not skip this step! Simply multiply the three dimensions using the below formula to get a volume measurement in cubic centimeters:

Length x Width x Depth = Volume

It is worth noting, though, that when calculating the volume of a box with the above formula, knowing which measurement corresponds with which dimension is technically optional. However, we highly recommend knowing this information to avoid future confusion or mistakes; it’s just a good habit to maintain.

But if you are not the best at mathematics and are looking for a tool to help make this process easier, use this convenient calculator to get exact volume measurements for your packaging.

The Issue of External Dimensions

Though we’ve shown how straightforward it can be to find the dimensions of your package, measure its exact length, width and depth and calculate for volume, there is still one essential consideration to keep in mind.

We mentioned earlier that you should measure your box’s internal dimensions, and we are about to explain why.

The industry standard for box dimensions relies on internal measurements, not external ones. The distinction between the internal and external dimensions is vital for obtaining packaging that fits your products perfectly. Interior dimensions are much more accurate for both the manufacturer and your product!

Most manufacturers even set a clear distinction between internal and external sizes, so while it may seem natural and easier to measure the outer dimensions of a box, the interior measurements are what matters for your custom packaging project.

Source: PakFactory

Measuring internal dimensions ensures your product can fit inside the box and is secure. Leaving minimal room for movement inside the package will guarantee your products’ safety during shipping and handling and allow your business to provide high-quality products every time.

On the contrary, if you measure external dimensions, it could prove problematic as external dimensions don’t factor in the thickness of a box, which could result in packaging that doesn’t quite fit your product.

This is especially important in the case of corrugated boxes.

Corrugated boxes feature a fluted texture weaved between two paperboards, making the material thick and adding a couple of millimeters to every measurement you take from the outer lining of the package.

So to get more accurate measurements, always measure the internal dimensions!

One Click Away

Now that you know how to find the length, width and depth (height) of your box, how to measure its dimensions, calculate the volume and have a better understanding of the importance of internal dimensions, you can now apply these easy processes to any packaging project!

That said, nothing beats the professional help of a packaging expert.

Visit Pakfactory and speak to a packaging expert regarding your custom packaging project and how it can benefit you and your business!