Table of Contents

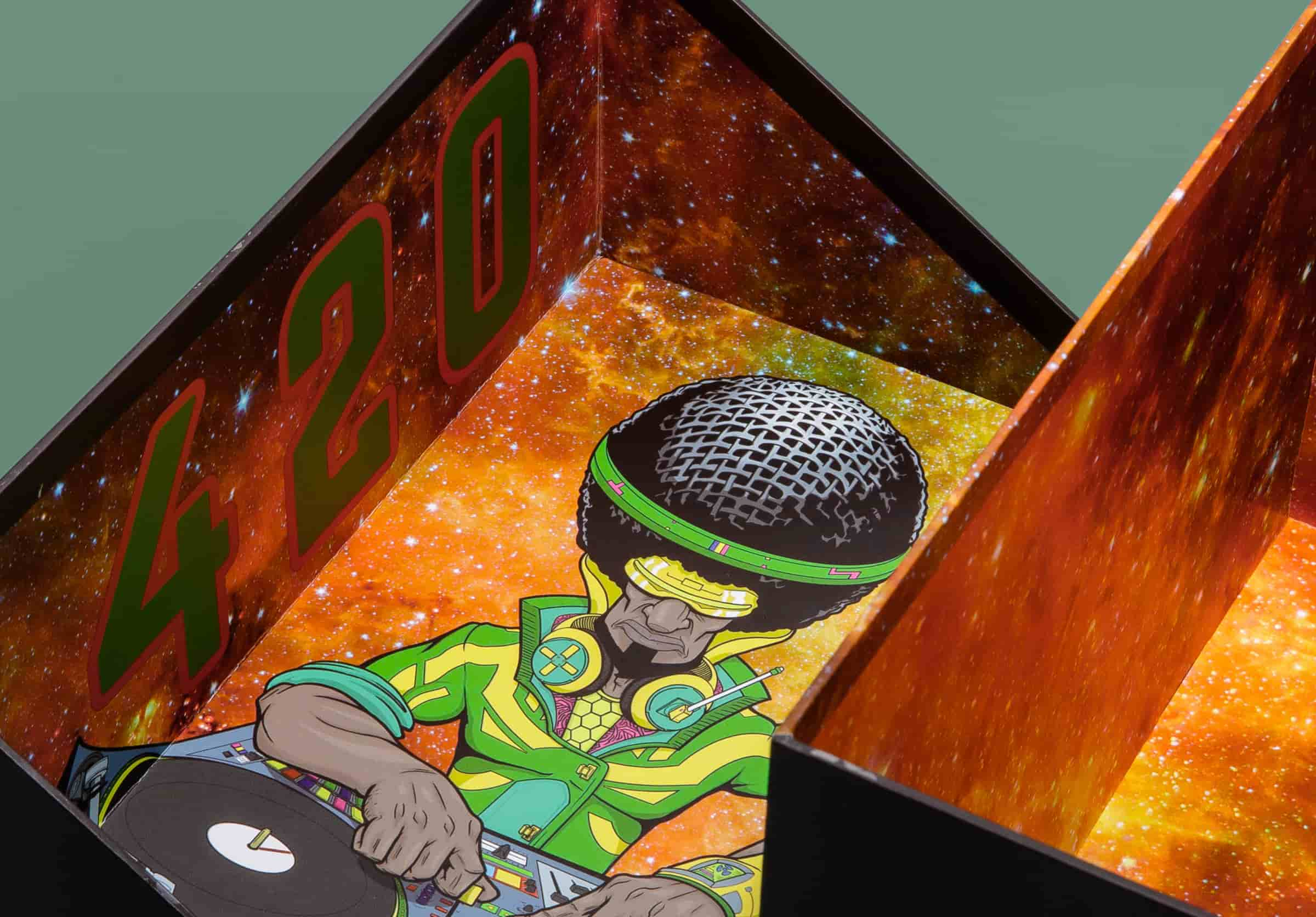

Offset printing is a highly sought-after process across many industries because of its exceptional quality, making it an ideal choice for enhancing the value of various products, packaging, and publications.

Unlike other printing techniques, offset printing is popular due to its ability to produce sharp, clear and consistent images that accurately depict the original artwork while maintaining the ability to print large volumes of materials efficiently.

But if you’re considering this printing process for your packaging project, it’s essential to understand how it works and what makes it a great option. So in this article, we’ll delve into these details, starting from the pre-press, printing, and post-press stages.

By understanding the ins and outs of offset printing, you can make an informed decision when deciding if it’s the right choice for your packaging project.

Source: PakFactory

What is Offset Printing?

Offset printing, or offset lithography, is a printing press technique that transfers ink from a plate to a rubber roller (or blanket) and then to various substrates to produce high-quality images and designs typically for mass production, such as printing large quantities of newspapers, brochures, stationeries, magazines, and of course, boxes.

For this reason, it is one of the most widely used printing options for its high-quality output and consistent results.

Source: PakFactory

Offset Lithography vs Digital Printing

Offset and digital printing are two distinct techniques with unique features and benefits. A detailed comparison is available via our Digital vs. Offset Printing article, but the main differences between the two include the following:

- Printing Process: Litho-printing uses plates to transfer ink onto a rubber blanket, which then applies the ink to the paper, while digital printing directly applies ink using an electronic file.

- Quality: Digital printing can produce good-quality images but does not match lithography’s sharp details and vibrant colors.

- Cost: For large print runs, offset lithography can offer a reduced unit cost with higher quantities. Digital, on the other hand, is better for smaller print runs.

- Turnaround Time: Digital printing has no plate setup time, and the printing process is faster.

- Customization: Digital printing allows for greater customization and personalization, including variable data printing, which offset lithography cannot achieve.

| Offset Lithography | Digital Printing | |

|---|---|---|

| Printing Process | Transfer ink onto paper through rubber blanket | Prints directly on paper |

| Quality | Higher quality printing | Limited to 4 colour process printing |

| Cost | Price goes down at higher volume | Cheaper for low volume printing |

| Turnaround Time | Longer setup time and ink drying time | Faster turnaround time, less setup time |

| Customization | No variable printing due to pre-made ink plates | Different versions of variable printing allowed |

Source: PakFactory

Overall, both techniques have advantages and disadvantages, so it ultimately depends on the specific needs that best fit your project. If you want to learn more about digital printing, we have you covered! However, if you want to continue learning about offset lithography, let’s move on to its various printing stages.

The Pre-Press Stage

The pre-press stage is a crucial step in the lithographic printing process that involves preparing digital files for the printing stage. This stage encompasses a range of activities, including designing, layout, and typesetting, which all play a crucial role in ensuring that the final printed product meets the desired specifications.

One of the key goals of the pre-press stage is to ensure that the digital files meet the specifications for the printing process, so during this stage, designers will work to verify fonts are appropriately embedded, the layout is formatted correctly and ensure properly formatted digital files for printing. This includes providing appropriately-sized files, correct file format, and that files are correctly color-managed.

The pre-press stage also consists of making any necessary adjustments to the digital files to ensure that they will produce high-quality prints.

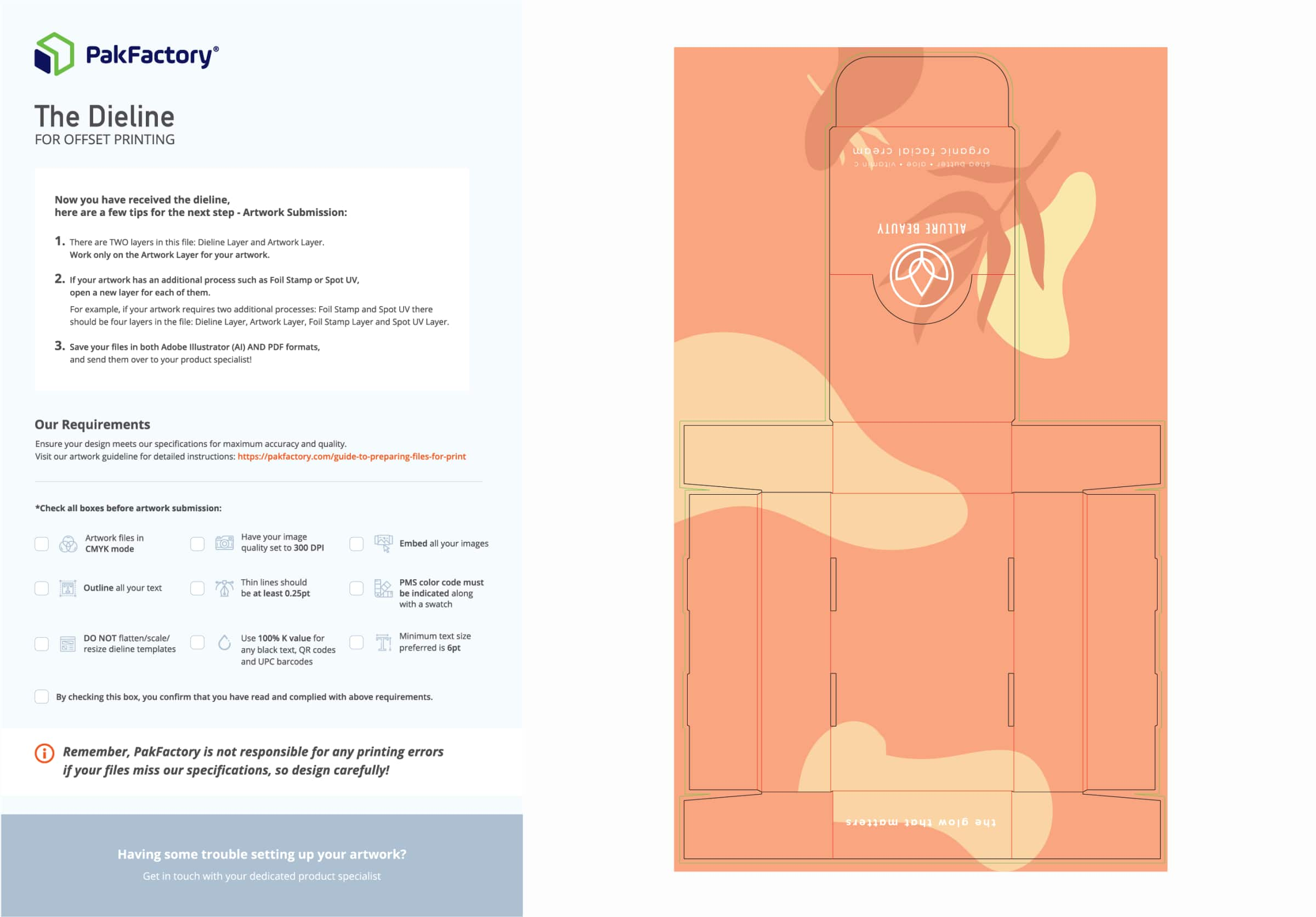

Source: PakFactory

Read more about how to prepare your dielines for print

Formatting digital files correctly and making necessary adjustments is essential because one of the most common mistakes designers make is not converting their work from RGB to CMYK, which ensures images are accurately coloured and of high quality and resolution.

So the best way to make sure you are preparing your files correctly is by contacting a product specialist of the packaging or printing company you are working with. They will help you through the pre-press stage, ensure the printing process runs smoothly, and that the final printed product meets the desired standards.

The Printing Stage

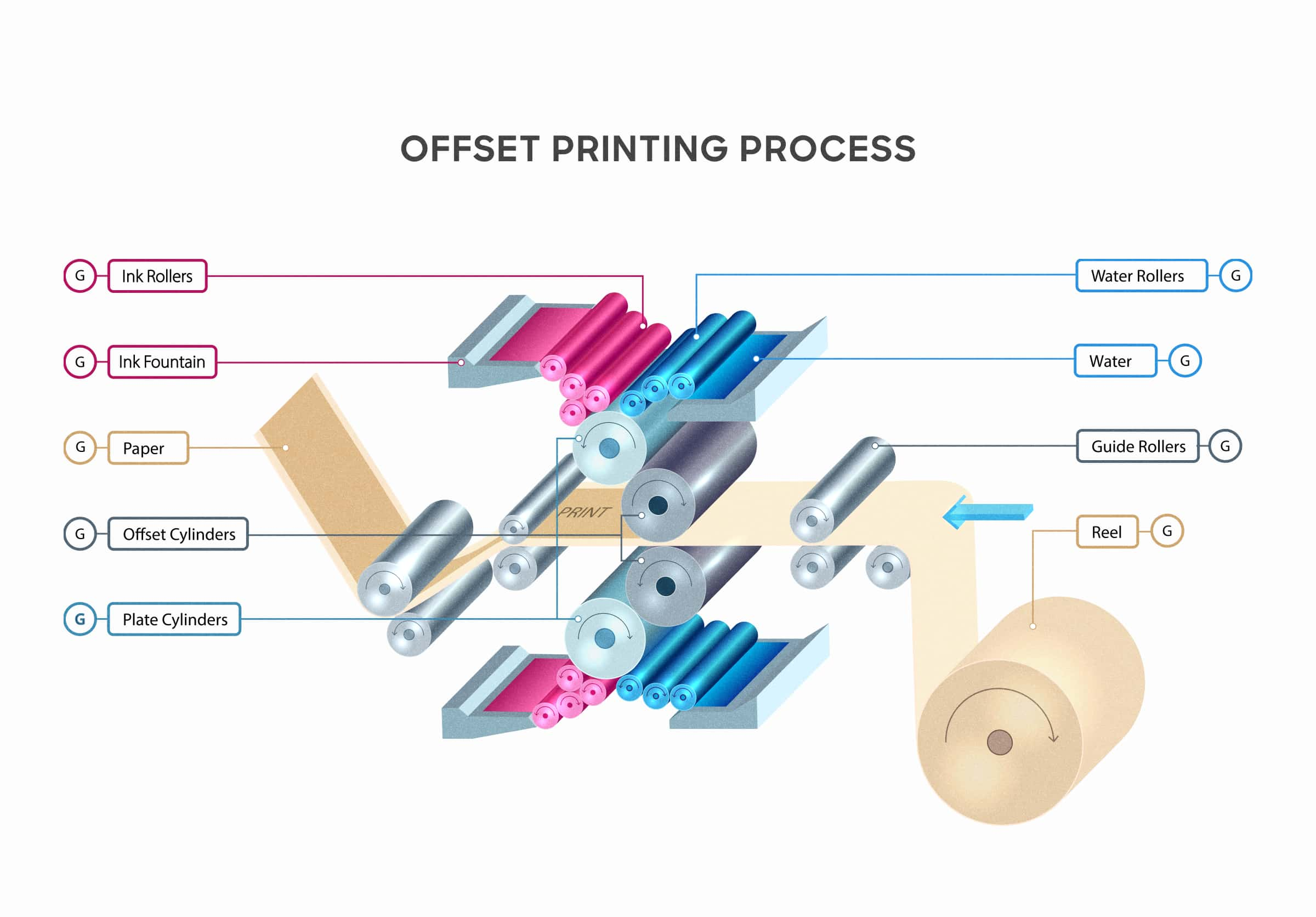

The next stage after pre-press is the printing stage, which involves using specialized offset lithographic printing machines that require equally technical operators to run correctly and transfer ink from printing plates to blanket cylinders and then to paper.

This process is highly efficient and can produce high-quality, consistent prints, making it a popular choice for commercial printing applications, and for good reasons!

One of the most significant advantages of litho-printing machines is their ability to handle a wide range of paper stocks, ink types, and printing plate sizes while producing high-quality prints with sharp, precise images and text. This advantage is possible because the ink transferred to the paper via the blanket cylinder allows for a more consistent and uniform application, as shown in the figure below.

In addition to the advantage mentioned above, these specialized machines can produce large print runs relatively quickly, further establishing offset lithography as an ideal choice for commercial printing processes and applications.

The Post-Press Stage

The final step of the litho-printing process is the post-press stage, where the offset materials are finished and prepared for distribution. This stage includes crucial activities such as cutting and finishing to ensure the final product meets the desired quality standards.

Cutting, which involves trimming the edges of the materials so they are uniform in size and the product looks neat and professional, typically uses a guillotine cutter that can simultaneously handle large stacks of paper.

Source: PakFactory

Finishing involves adding special coatings or embossing to enhance the appearance of the offset materials. For example, a glossy or matte coating can give a professional, polished look. Conversely, embossing can add texture and depth to the design, making it stand out and catch the reader’s eye.

Quality Control and Inspection

When the printing process is complete, it’s time to move on to quality control and inspection, which is crucial in ensuring that the final product meets or exceeds the customer’s expectations.

To maintain the highest level of quality, post-press technicians use many various tools and techniques to inspect the finished products. This includes using colorimeters and densitometers to measure the color accuracy and consistency of the prints.

Source: PakFactory

Technicians also use magnifying lenses and microscopes to closely examine the printed materials for imperfections or defects, such as smudges, streaks, or misalignments. If any issues appear, they are promptly addressed, whether it involves reprinting the entire job or making minor adjustments.

Types of Offset Litho-Printing

Web Offset Printing

Web offset lithography is typical in the printing of newspapers and boxes. In this process, rolls of paper are fed continuously through the machine press and can produce over 5,000 printed materials. In addition, the paper is cut to create identical sheets during this process.

Web-fed offset printing presses can produce over 3,000 papers per minute, w translating to about 80,000 identical sheets per hour, which makes it an ideal option for organizations that need to have large quantities at a fast pace to meet tight deadlines.

Sheet-Fed Offset Printing

Unlike Web-fed, sheet-fed offset lithography produces smaller quantities as sheets of paper are fed individually to the machine. However, this method is still considered a quick printing option compared to other alternatives.

Sheet-fed printing can produce up to 12,000 sheets to 24,000 per hour, but with modernization, this type of printing has significantly improved in speed, allowing it to perform similar functions as the web-fed press.

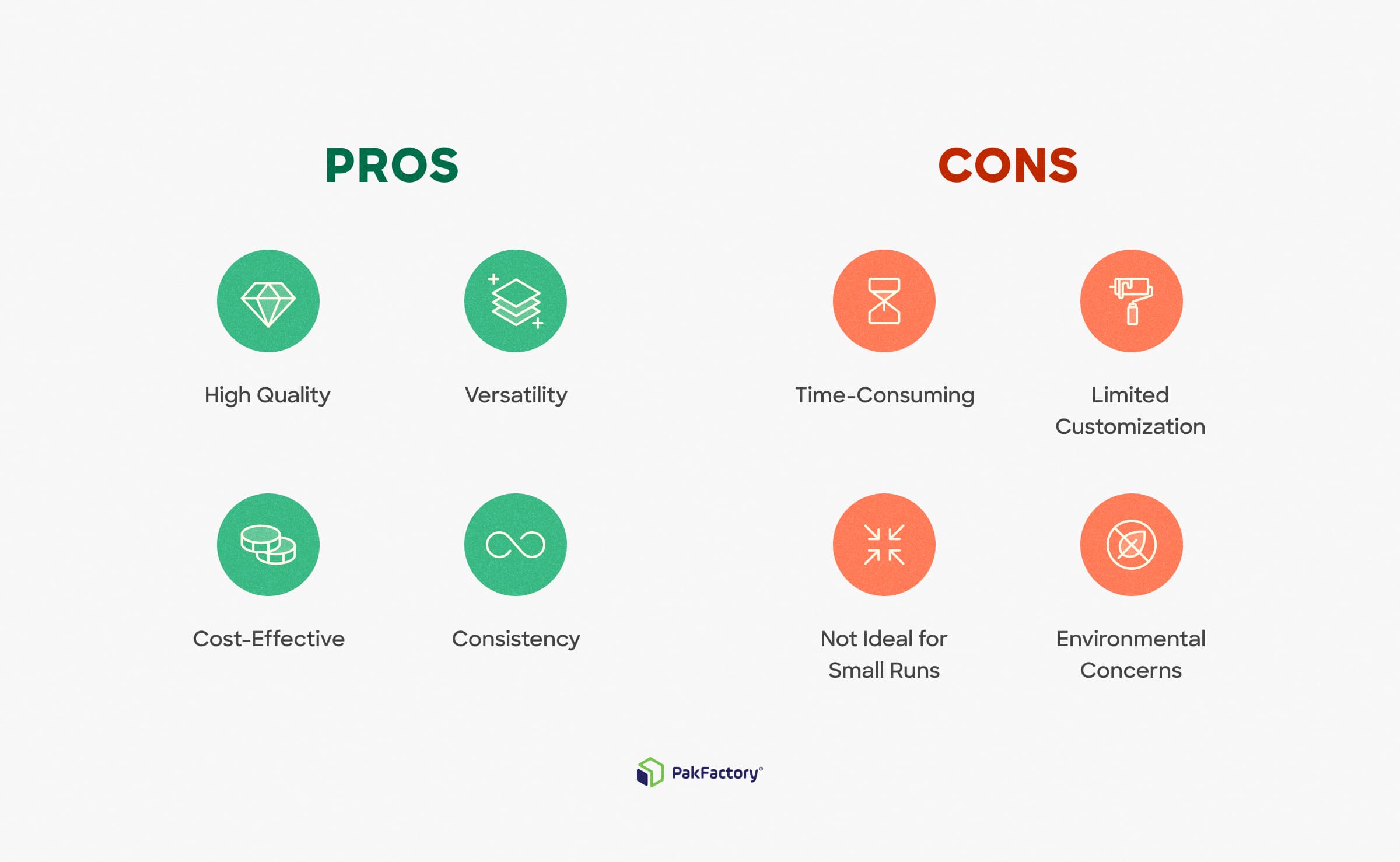

The Advantages and Disadvantages of Modern Offset Printing

Source: PakFactory

Advantages:

High Quality: This process produces high-quality images and text with excellent color accuracy and sharpness, making it an ideal choice for packaging projects that require a professional and eye-catching appearance.

Versatility: It can be used on various surfaces, including paper, cardboard, and plastic, making it a versatile printing technique for different types of packaging.

Cost-Effective: Litho-printing is cost-effective for large-scale production runs and has lower setup costs than other printing methods.

Consistency: Offset printing produces consistent results across large production runs, ensuring that the final product meets the desired quality standards.

Disadvantages:

Time-Consuming: Printing can be time-consuming, requiring several steps, including preparing printing plates.

Limited Customization: While offset printing is versatile, there may be better options for highly customized packaging designs. It may require additional setup time and costs to create custom printing plates.

Not Ideal for Small Runs: Litho-printing is not cost-effective for small production runs, as the setup costs can be high compared to other printing methods.

Environmental Concerns: Using chemicals in the printing process can have ecological implications. It may require proper disposal and handling to minimize their impact.

Is It Right for You?

Offset lithographic printing is a crucial and widely-used printing technique in various industries, including packaging.

As technology evolves, offset printing will continue to play a significant role in the industry and provide new opportunities for businesses to create innovative and visually appealing packaging solutions.

So if you are considering using this printing technique for your next packaging project, you can feel reassured that this method will provide you with many options to create high-quality, versatile and cost-effective prints that will meet and exceed your requirements!