Table of Contents

It is common, especially if you are new to printing & packaging, to expect a specific color or quality that matches what you see on a screen.

However, the truth is that the printing output cannot 100% match what we see on the monitor based on the RGB vs CMYK color output theory.

Yes, you can calibrate the quality of the output to try and mimic how it should appear, but it will depend on the technique and technology you choose.

This is where many business owners, designers, and marketers tend to make mistakes and risk the quality appeal of your brand.

Remember, though, that this doesn’t necessarily mean you have to choose more costly options.

There are many ways to make cost-effective decisions for quality results.

Here we’ll help you choose the most suitable printing methods for your custom packaging project.

Understanding the differences in output based on artwork objectives, costs, and capabilities is essential to making the right choice to optimize your branding opportunities.

What are Digital and Offset Printing?

The two main printing methods you can use for your packaging are offset lithographic printing and digital printing.

Offset Print

Offset print uses metal plates that rapidly layer color onto sheets and stamp it onto paperboard.

This is the standard method used for newspapers and magazines.

Offset is preferable for designs requiring additional processes such as spot UV and foil stamping and requires a volume of over 1000 units.

And while offset printing is more effective for large volumes, it doesn’t necessarily take longer to print your project.

Offset printing offers superior image quality and cost-efficiency for large-volume print runs but is too expensive for most low-volume projects and takes extra time to complete.

Digital Print

Digital print, on the other hand, is how your home office laser or inkjet printer works.

It offers quick turnaround times and makes low-volume jobs affordable.

It’s also easier to create variable data print runs using a digital printing press.

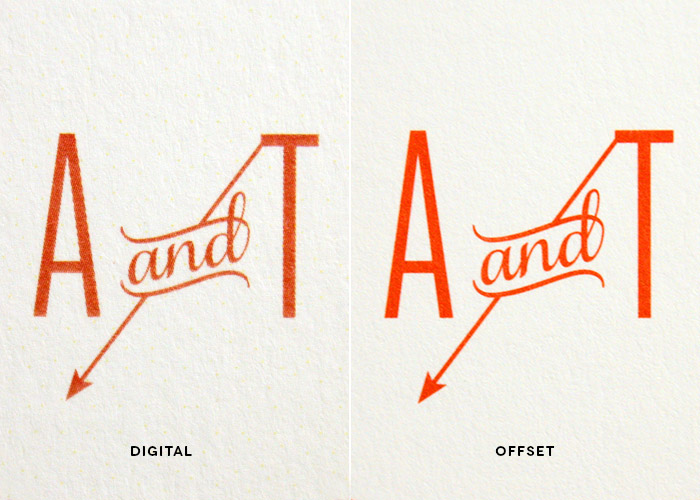

However, digital printers can’t quite match the color fidelity and material flexibility that offset printing offers.

According to Smithers Pira, digital printing accounts for 16.4 percent of global print and packaging in terms of value but only 3.9 percent of the print industry’s volume, suggesting that digital printing is the best low-volume print choice.

But there is more to the question than just comparing print volume.

For smaller runs and simpler designs on e-commerce packaging, digital is the way to go.

Keep your estimated print volume in mind and choose the right printing method for your packaging material.

Which Method for Which Package?

Now that you have a bit more understanding of offset printing and digital printing, it’s time to determine which method to use.

Rigid packaging typically requires offset printing. If you’re going to print on luxury boxes with a high setup cost for production, you might as well print in offset to get the best quality possible.

Corrugated packaging can benefit from either digital or offset. However, for smaller runs, digital is the best option.

Paperboard packaging typically requires offset, especially for cosmetic, pharmaceutical and small retail packaging.

This is because offset provides a clearer and more vivid printing output for smaller texts and designs. Maintaining clear and concise information on your packaging is crucial for communicating important information with consumers.

Comparing Color Depth and Coating Options

Although offset printing can be more expensive, it outperforms digital printing in terms of brightness and color depth.

Offset produces the clean, crisp, and attractive color output you see in retail stores, while digital printing produces excellent quality for simpler designs (perfect for e-commerce packaging).

In addition, offset printers can utilize the Pantone Matching Color System to match inks perfectly, whereas digital printers can only approximate these colors using color calibration.

Offset printers can even print white ink on kraft paper, while digital cannot.

Offset Printing Has More Coating Options

Along with outperforming digital printing with brightness and color depth, offset printing also allows for a greater variety of coating options that are not available with digital printing:

Prototyping with Digital and Offset

So you now know the benefits of each printing method and which package best works with which process. Now it’s time to begin prototyping your project.

Prototyping in offset is possible but requires more time and cost.

But no rule says you must choose between one or the other. Offset and digital printing can complement one another in most packaging orders.

Using digital printing to create packaging prototypes and opting for offset printing for the production process is a cost-effective way to maintain quality printing opportunities.

Optimal Order Quantities

For folding cartons and rigid boxes, no matter what quantity, offset printing is recommended.

However, if you are producing in corrugated, orders lower than 500 pieces should consider digital printing for cost efficiency and offset for pieces larger than 1000-2000 due to better quality and cost optimization.

Still trying to figure out where to start?