Table of Contents

In order to determine why the RGB color model is not used in printing and packaging, we need to examine the basics of the RGB color model, beyond just discussing what the acronym stands for.

RGB Color Model

RGB stands for Red, Green, and Blue.

RGB is a device-dependent color model and can only really be used successfully on screens and, in some cases, conventional photography.

This refers to the colors you are able to see on the screen right now, it does not translate the same way through printing.

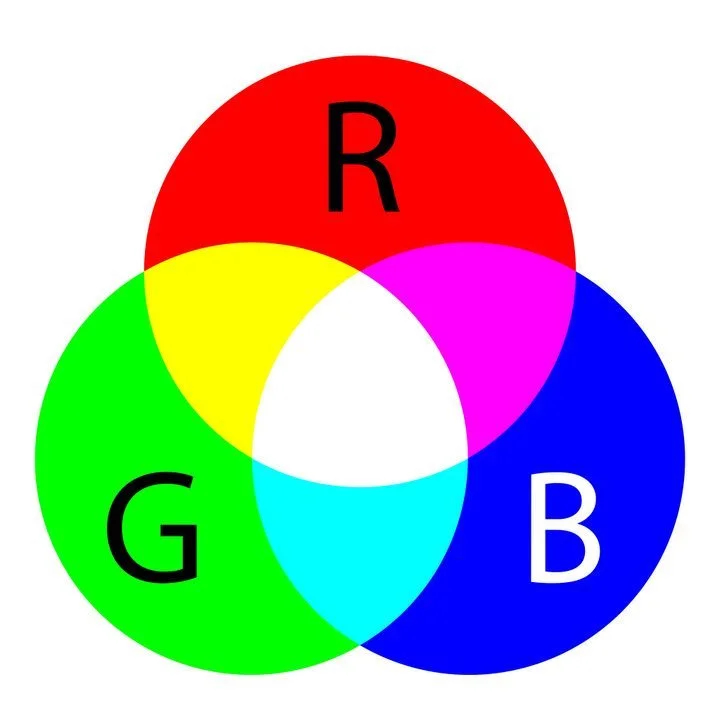

Every color that they displayed is a combination of Red, Green, and Blue.

For instance, a combination of red and green produces yellow; a mix of green and blue yields cyan, and adding blue to red gives you magenta.

All three basic colors, when added together, produce white as a result. Unlike CMYK, RGB is considered to be an ‘additive’ color system for this reason.

Combinations of RGB Color

Apart from these eight colors (red, green, blue, yellow, magenta, cyan, white and black), several other colors can be displayed too.

How this is achieved by mixing various color concentrations to create the desired color on the screen.

Each of the three basic colors (red, green, blue) has six strengths –

- 0%

- 20%

- 40%

- 60%

- 80%

- 100%

This also means there are 63 or 216 colors in total.

However, this is only in theory.

Hardware problems with display systems result in each basic color only being displayed with strengths of 0%, 2%, 10%, 28%, 57%, and 100%.

Therefore, colors (except the eight colors mentioned above, which rely on either 0% or 100% strength for each basic color) would not be displayed accurately.

As technology progresses, programmers and engineers are able to find new ways to achieve color correction on computer and television displays through research, new tools, and advanced coding.

While this opens many opportunities for technological advancements, the RGB color system still poses issues for printing and packaging!

Why is RGB not ideal for Printing & Packaging?

In most printing processes, RGB color space is usually converted to CMYK before creating the artwork.

Read more on the CMYK Color Model

Essentially, any colors produced with RGB on the digital space will not create the same output on the physical print.

This is based on the color gamut, which in other words means that translating RGB to CMYK usually allows the color to convert only as close to the original appearance of the display screen.

Therefore, working in a CMYK color space allows the artwork to look exactly or as close as possible to the real-life design you will get when it becomes printed on paper or packaging.

This applies to;

What happens if you’ve created a design using the RGB color model?

The good news is your artwork designs can very easily be converted to the CMYK color model through whatever design program you may be using.

However, the drawback of converting RGB color model designs to CMYK is that colors may need to be corrected again to produce something more close to the original design you created using RGB.

Here is a video by Print Place on how to convert RGB to CMYK:

Applications of the RGB Color Model

RGB on Screen

As mentioned previously the most common use for the RGB color model is to display digital designs and images.

It is used in;

- Cathode ray tubes

- LCD displays

- LED displays

The one you’ll be most familiar with today is the LED displays. This includes things like your TV and computer monitor.

Each pixel on these screen types displays the RGB colors and creates images and designs we recognize.

The RGB color model is also used in component video display signals.

Remember the plugs at the back of your TV that are Red, Green, and yellow?

That is in fact the RGB color system is used to signal these specific colors to the television so you and I can watch our favorite movies and series from the comfort of our couch!

RGB on Cameras

Digital cameras heavily rely on the use of the RGB color system through CMOS or CCD image sensors.

Current digital cameras have an RGB sensor which helps to determine the exposure of your images and create accurate photographs.

While the RGB color model has been really helpful in advancing technology and creating the systems we now all know and use, it’s not the best color system for printing and packaging.

You’ll end up with distorted colors and ultimately will create dull and strange designs and prints.

That’s why opting for the CMYK color system for custom packaging and printing will ensure you higher-quality results.