OPTION

RB002

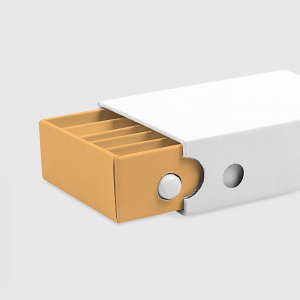

Wine Tube Box

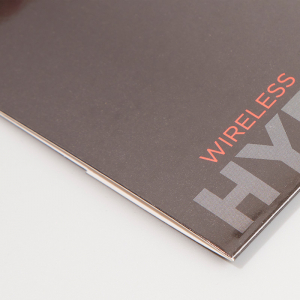

Key Features

- Robust rigid grey board

- Cylindrical shaped box exclusively designed to store whiskey bottles with care and to avoid temperature fluctuations

- 4 times thicker board for added protection from breakage and to maximize the life of the liquor or wine

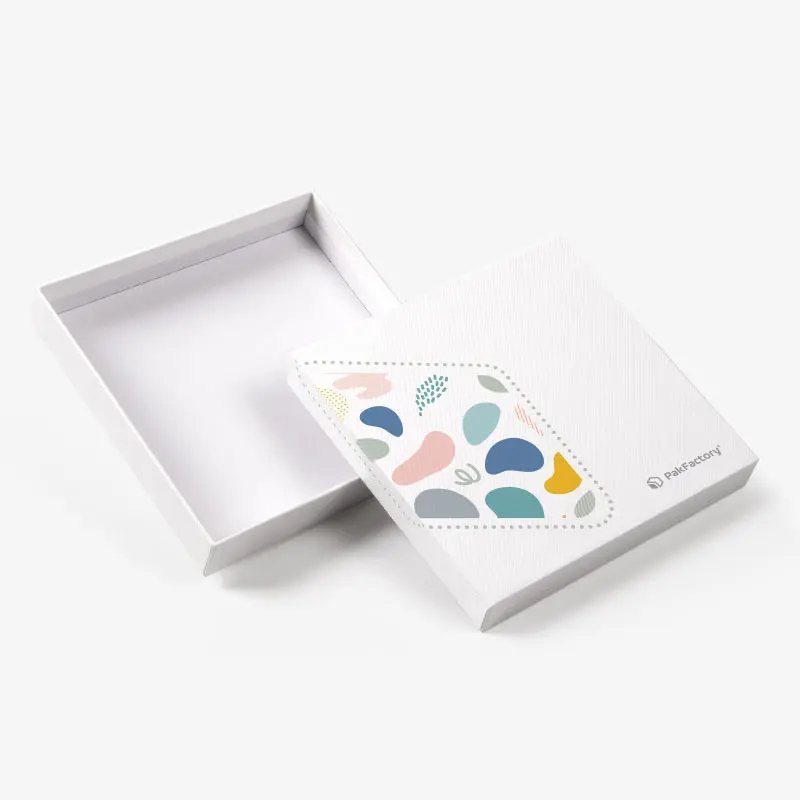

- Printed paper covering to make a strong brand identity

- Can be fully customized in color, print & style

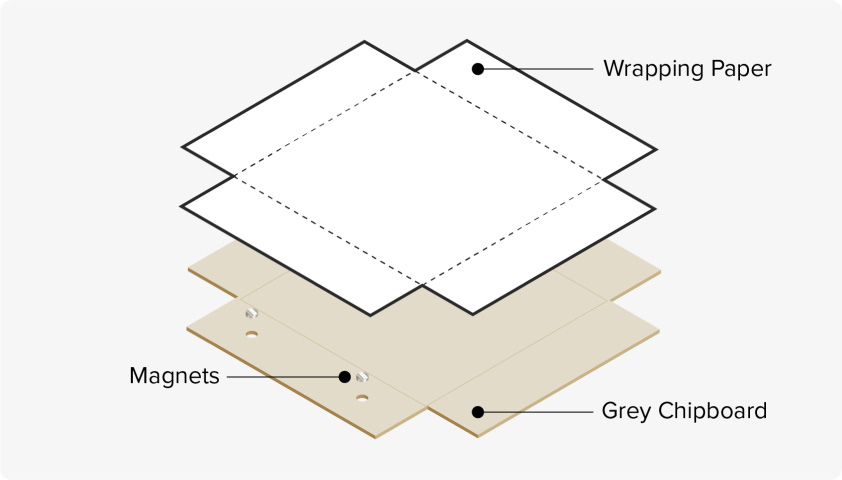

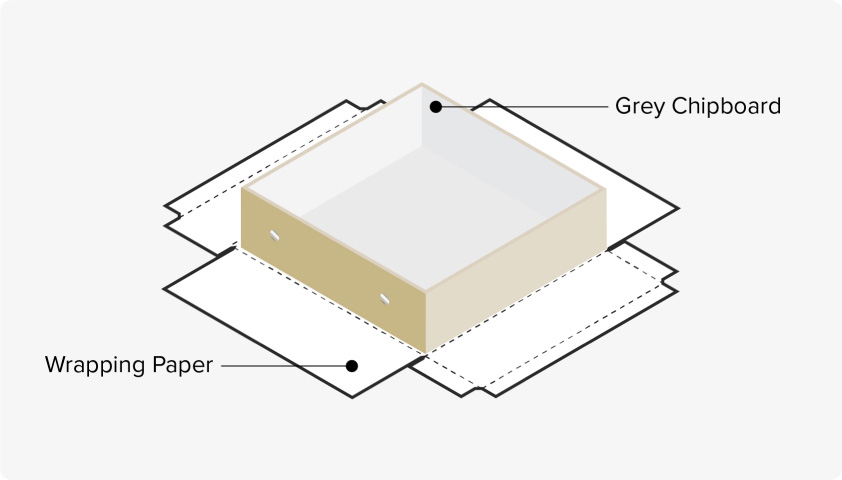

Materials

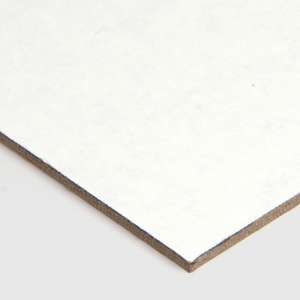

OP041

Grey Chipboard Cardboard

OP106

Duplex Chipboard

Wrapping Paper Options

OP502

SBS C2S

OP505

Natural Brown Kraft

OP506

White Kraft

OP507

Black Kraft

OP512

Metallic Paper

OP513

Holographic

OP514

Textured

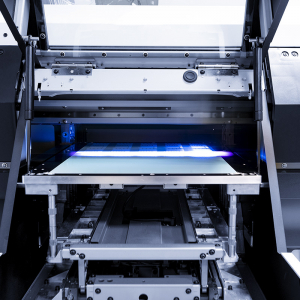

Printing Methods

Inks

OP001

Water-based Inks

OP002

Soy/Vegetable Based Inks

OP004

Fluorescent Color Inks

OP006

Oil Based Inks

OP007

Pantone

OP008

Pantone Metallic

Finishing

OP009

Aqueous Coating

OP010

UV Coating

OP011

Spot Gloss UV

OP012

Soft Touch Coating

OP013

Varnish

OP014

Lamination

OP015

Anti-scratch lamination

Add-on

OP136

Plastic Handles

OP137

Leather Handles

OP138

Macramé Handles

OP139

Ribbon Handles

OP140

Ribbon & Bows

OP141

Metal Locks

OP142

Magnetic Locks

OP143

Child Resistant Locks

Our Ordering Process

Looking for custom packaging? Make it a breeze by following our four easy steps - soon you’ll be on your way to meeting all your packaging needs!

Customize your packaging

Choose from our vast selection of packaging solutions and customize it with our wide range of options to create your dream packaging.

Add to quote and submit

After customizing your packaging, simply add it to quote and submit quotation to be reviewed by one of our packaging specialists.

Consult with our expert

Get expert consultation on your quotation to to save on costs, streamline efficiency and reduce environmental impacts.

Production & shipping

Once everything is ready for production, have us manage your entire production and shipping! Just sit and wait for your order!