Table of Contents

Packaging waste has been a long-time issue in the retail industry.

Heaps of plastic and molded foam end up in landfills and remain there for lifetimes. The pandemic’s shift to online shopping accelerated the e-commerce industry, making ordering everything from groceries to furniture more convenient. However, this convenience also brings a greater responsibility for businesses to go green. The environmental impact of plastic packaging, particularly its contribution to increasing waste in landfills, underscores the urgency for businesses to adopt more eco-friendly practices. It’s essential to assess the life cycle of sustainable packaging materials to ensure brands meet their sustainability responsibilities.

This comprehensive guide explores different eco friendly materials for packaging, highlighting their benefits and applications to help businesses and consumers make smarter choices and pave the way for a greener future.

Recyclable Packaging

Recyclable packaging is the most common type of sustainable packaging used widely across the retail industry. Two popular recyclable packaging materials are kraft paper and molded pulp.

1. Kraft Paper

Kraft paper, derived from wood pulp, is renowned for its durability and versatility. According to the American Forest & Paper Association, “the United States recycles about 68% of all paper products.” Because kraft is a raw material, it can be soaked, chopped, cooked, strained, cleaned, bleached, and reformed to create new paper packaging, bringing the material full circle. While it’s true that kraft loses its durability the more it is recycled, the great thing about recyclable materials is that most, if not all, are biodegradable. This means that at the end of its life cycle, it can be easily composted, once again bringing the material full circle without negatively impacting the environment.

Kraft paper’s natural brown hue exudes a rustic charm, often used in packaging for its strength and aesthetic appeal. Beyond its use in simple regular paper bags, kraft paper is also made into corrugated cardboard and folding cartons for sturdy shipping boxes and mailers.

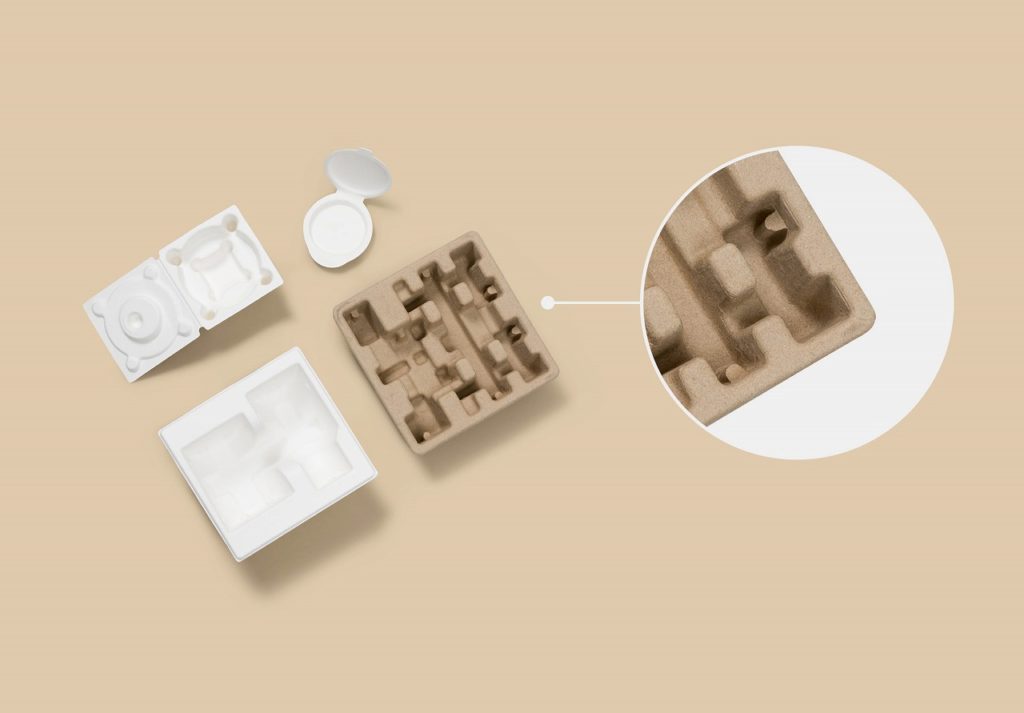

2. Molded Pulp

Molded pulp is one of the popular raw materials made from recycled paper and cardboard. It is commonly used for protective packaging, such as box inserts, egg cartons, and beverage trays. Molded pulp is praised for its shock-absorbing properties and its ability to be recycled repeatedly, reducing the need for virgin materials. According to a study by the Environmental Protection Agency (EPA), “recycling one ton of paper can save 17 trees, 380 gallons of oil, and 7,000 gallons of water.” Its adaptability allows it to be molded to the product into various shapes, providing custom-fit packaging solutions. Hence, it is an great alternative to plastic inserts

Compostable Packaging

Compostable packaging materials decompose into organic matter without leaving harmful residues. However, for effective large-scale use, they depend on the infrastructure of composting and waste management programs to complete the waste cycle. Examples of engineered compostable materials include bioplastics, mushroom packaging, and cornstarch packaging.

3. Bioplastics

Bioplastics come from renewable resources such as corn starch, sugarcane, and potato starch. Unlike traditional plastics, bioplastics can naturally decompose under specific conditions, helping to cut down on pollution. A popular bioplastic is polylactic acid (PLA), often used in packaging. PLA is clear, durable, and compostable, making it a great alternative to petroleum-based plastics. These attributes are making bioplastics increasingly popular, especially in the food and restaurant industries, where they provide the necessary durability and hygiene while also breaking down quickly after use.

4. Mushroom Packaging

Mushroom packaging is an innovative, mycelium based packaging material that’s still in its early development stages but holds great potential as a compostable packaging solution. Made from agricultural waste and mycelium (the root structure of mushrooms), this material is grown using minimal energy and resources. It naturally decomposes in a compost heap, enriching the soil with nutrients. Sturdy and lightweight, mushroom packaging is perfect for cushioning fragile items during shipping.

5. Cornstarch Packaging

Cornstarch, as one of the renewable sources, is made from the starch of corn kernels and serves as a compostable alternative to polystyrene (Styrofoam) and plastic. It can be molded into various forms, such as trays, lids, bags, plates, containers, and packing peanuts or pellets. Under composting conditions, cornstarch packaging breaks down quickly and leaves no toxic residues. Additionally, cornstarch packaging is marine degradable, meaning it dissolves in water and can serve as food for marine life. Its applications are broad, including protective packaging and disposable cutlery and plates.

Reusable Packaging

Reusable packaging is designed to be long-lasting, promoting reuse and significantly supporting the circular economy. As one of the most environmentally friendly solutions available, reusable packaging reduces the need for single-use materials, which are a major contributor to global waste. Common examples of reusable packaging include shopping bags, tin boxes, and collapsible or magnetic rigid boxes.

6. Reusable Shopping Bags

Reusable shopping bags, often made from cotton, hemp, or recycled materials, offer a sustainable alternative to plastic bags. A study by Waste Management shows that “a single reusable bag can save over 700 disposable plastic bags throughout its lifespan.” They are durable, washable, and designed for multiple uses, significantly reducing plastic waste and promoting sustainability. These reused bags are practical and provide a branding opportunity for your business, serving as a canvas for creative designs and logos.

7. Tin Boxes

Tin boxes, typically made from tinplate, are robust and reusable, making them ideal for a variety of products, from treats and food to cosmetics. Tin can be processed and returned to the production cycle without any loss in quality. Additionally, its magnetic properties make it easy to extract from waste streams.

For luxury brands aiming to enhance their sustainable practices, it’s important to note that most tin boxes are fully recyclable. Their durability makes them a favorite for eco-friendly packaging while still providing a luxurious look and feel.

8. Collapsible/Magnetic Rigid Boxes

Magnetic closure rigid boxes feature two magnets that lock together to securely seal the box. Their sturdy construction makes them popular among consumers for reuse, offering a sustainable packaging solution for premium products. The magnetic closure provides a sleek unboxing experience that encourages further reuse. Additionally, collapsible magnetic closure rigid boxes can be packed and shipped flat, reducing shipping and handling costs as well as the carbon footprint.

Biodegradable Packaging

Biodegradable packaging materials are gaining popularity as a sustainable alternative to traditional packaging. These green packaging materials naturally break down over time and can be dissolved in water, providing food for marine life. In addition to cornstarch, other examples of biodegradable packaging materials include bagasse, water-soluble plastic, and cassava root.

9. Bagasse

Bagasse, a fibrous by-product of sugarcane, is repurposed into eco-friendly packaging materials. It is commonly used to make disposable tableware, food containers, and trays. Bagasse-based packaging is both biodegradable and compostable, decomposing rapidly under composting conditions. Its sturdy nature makes it a suitable replacement for plastic and Styrofoam packaging.

10. Water-soluble Plastic

Water-soluble plastic, often made from polyvinyl alcohol (PVA), dissolves upon contact with boiling water. This innovative material is used for packaging items such as garment bags, detergents, and medical supplies. Its ability to dissolve completely in water helps reduce plastic packaging waste and prevent pollution.

11. Cassava root

Cassava root is one of the plant based materials made from the starch of cassava plants. It is fully biodegradable and compostable, breaking down into non-toxic components. It can be made into products like bags, films, and food containers. The manufacturing process is also sustainable, utilizing a renewable resource that grows abundantly in tropical regions.

Sustainable Printing

Sustainable printing is as important as using sustainable materials for packaging. It involves using eco-friendly inks and coatings to ensure that the packaging is fully recyclable.

12. Sustainable Coating

Sustainable coatings, such as water-based primers, barrier coatings, varnishes, and heat-sealing options, enhance the durability and appearance of packaging without compromising its recyclability or compostability. These coatings provide a protective layer that makes the packaging resistant to moisture and abrasion. Unlike conventional coatings, sustainable coatings do not release harmful chemicals into the environment.

13. Sustainable Inks

Popular sustainable inks include soy ink, vegetable ink, and water-based ink. These inks are eco-friendly alternatives to traditional petroleum-based inks, which cause air pollution and pose health risks. By using these sustainable inks, companies can maintain environmentally friendly practices and ensure that packaging materials like printed corrugated boxes and folding cartons remain fully recyclable.

Conclusion

Overall, embracing earth friendly packaging materials is more than just a trend; it’s a crucial step towards green packaging. Businesses that adopt these materials not only help preserve the environment but also meet the growing demand for sustainable packaging from conscientious consumers. By using recyclable, compostable, reusable, and biodegradable packaging materials, along with sustainable printing practices, your business can help reduce the ecological footprint and promote a greener future.

Thinking about switching to eco friendly packaging material? Explore PakFactory’s eco-friendly packaging solutions to learn more!