Table of Contents

Many brands, both established and new, aren’t entirely sure how much it costs to design custom packaging.

Because of this, businesses tend to opt for stock packaging that doesn’t necessarily do their brand justice and in turn hurt their reputation.

The purpose of custom packaging is to bring your branding to the forefront and make an impact that your target market will find hard to forget.

This is difficult to do with stock packaging that your competitors are likely also using.

The cost of custom packaging can be a little mysterious especially if you are not familiar with the industry and what factors can affect your costs.

Truth be told, the costs lie in your hands and you have the power to make sure it fits within your budget!

The first step to determining your custom packaging costs would be to establish the type of product you are selling.

This could include;

- Luxury Products

- Cosmetics

- Food

- Electronics

- Or anything really!

Determining what industry your product will be serving will allow you to narrow down your choices and in turn get a better understanding of what your costs will entail.

This includes determining how you will be serving your industry niche.

Making a distinction between e-commerce and retail packaging will also affect your pricing options drastically as these packaging solutions will be serving different purposes.

Furthermore, determining your time frame of your product launch will also have an impact on your costs as some packaging solutions can take more time and care to produce, such as rigid packaging.

Once these factors are determined, you can start comparing the core cost considerations for your custom packaging below.

The Cost of Materials and Finishes

The first cost when evaluating your expenses for custom packaging will be the material and finish.

This will narrow down your options when you determine your structural design and printing costs.

There are a variety of materials to choose from, which vary in price. After all, most of your expenses will cover sourcing and shipping your packaging materials to you.

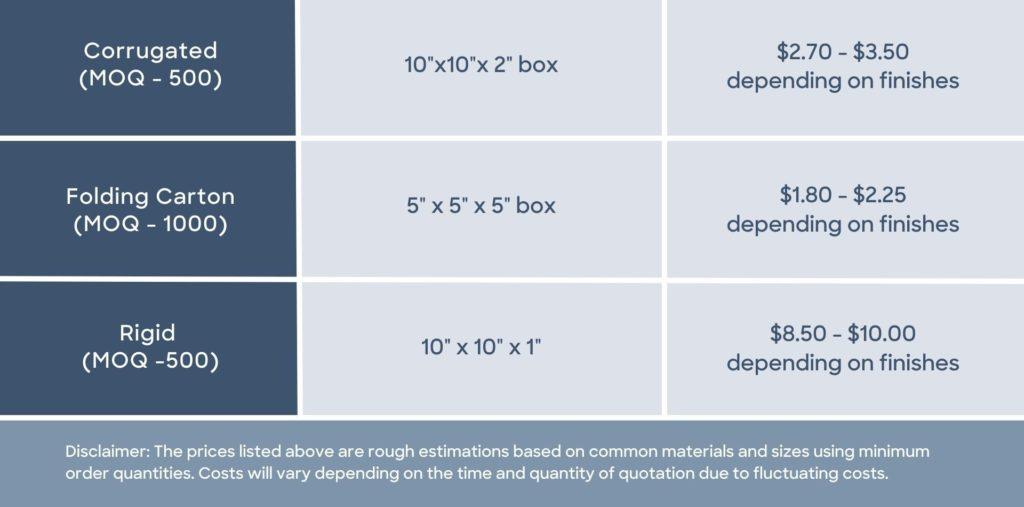

Here is a price list estimation for you to refer to:

Depending on your product launch plan, you may want to consider opting for more cost effective packaging, as they are much more time efficient to produce.

Sometimes, opting for the highest quality packaging materials isn’t the best way to optimize your custom packaging.

You need to distinguish between what you ‘want’ vs. what you ‘need’.

Think of it this way; you may want to have an original Picasso on your wall, but you don’t necessarily need it, a printed replica will have the same effect.

So, if you’re running a smaller business, it’s best to find a custom packaging company that will optimize your costs and provide you with the minimum order you need!

There are many cost effective material options that will communicate your brand narrative just as well as the highest quality packaging will.

As discussed previously, the industry your product is serving and how it is serving it will help you determine the material and finish of your custom box.

Once that’s decided, you’ll need to settle on a volume of custom packaging required.

Smaller boxes tend to be cheaper to produce and ship, but larger boxes can also be cost-effective depending on the minimum order.

In general, you will be paying less per unit the larger your order is, some materials simply offer cost effective small orders while other materials may not.

Let’s explore and evaluate your material and finishing options and their costs.

Keep in mind; Manufacturers will not advise you on material optimization. However, solution providers will help you optimize on your costs based on your product needs.

Corrugated

The safest option, corrugated, remains a popular material choice for custom packaging because of its durability and low cost.

They are easy to assemble, work for a large variety of products and are cost effective to produce, making them a more versatile option to consider for your material choices.

Corrugated packaging is a popular option for e-commerce businesses as they are cost/time effective and sustainable to produce.

Its thick texture offers support to heavier items while also offering optimal protection to your more fragile items.

Furthermore, Corrugated packaging offers a large variety of finishing opportunities for you to consider.

These include;

Varnish

For small to medium-sized corrugated projects, gloss varnish is recommended to increase production efficiency, generate a faster turnaround time and generate an overall lower unit cost.

Lamination

A laminated coating provides your box with the ultimate protection of your artwork, but can sometimes be pricey depending on how much of your budget you allocate to each aspect of your project.

Wax Coatings

Wax coatings are cost effective and water/grease resistant. This coating may only be necessary if you are packaging food or medical products. Keep in mind that because corrugated packaging is made from organic materials, you do not need a wax coating to package food and medicine safely.

While finishing options for corrugated packaging are available, this doesn’t necessarily mean you have to opt for one or the other, you can choose to opt for none at all.

Choosing no coating for your packaging in turn keeps your corrugated packaging costs low.

Keep in mind, corrugated packaging may not be a necessity if your products are not very prone to breakage.

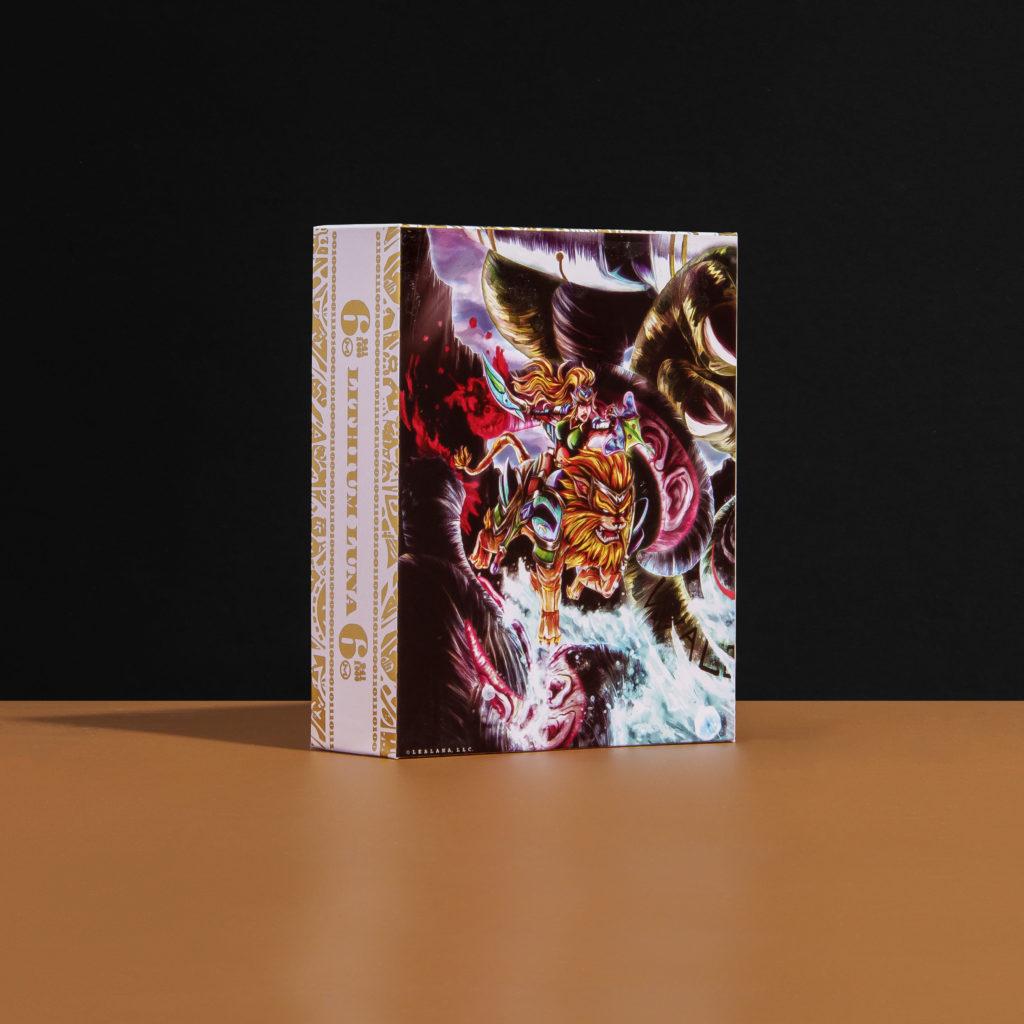

Folding Carton (White and Kraft)

Folding Carton is an excellent choice for those looking to save on cost and products that do not require a high level of support and protection.

If you’re looking to pay low shipping costs, folding cartons are your best bet because it is lightweight, allowing for larger orders for less costs.

Bear in mind, kraft paperboard tends to be a bit higher in cost than SBS white paperboard, so you’ll want to make a note of these cost differences when evaluating your custom packaging options.

Kraft is produced straight from the source, giving it it’s texture and feel, making it a little pricier than SBS white paperboard.

SBS white paperboard is made from bleached recycled paper, making it a little bit more affordable as it is a reused material.

The coating process of SBS white paperboard offers a surface for high quality printing and finishing that allows you to showcase your brand identity.

Although Folding Carton is your cost effective option, it still allows for a luxurious high end feel through its printing and finishing capabilities and of course your branding!

Because of folding carton’s versatile nature and cost effectiveness, you can afford to splurge a little on special finishes and coatings.

The finishes include, but are not limited to;

Lamination

Laminated paperboard boxes are widely regarded to have the best quality, but are typically more expensive due to its protective properties. Long-run projects typically prefer to use lamination due to their longevity and dust resistance.

UV & AQ Semi-Gloss Finishing

If you’re looking for a less expensive option, you might want to consider low gloss AQ coating. Since AQ Semi-Gloss is water-based, it is a food-safe alternative.

Opting for Kraft and an AQ UV finish will keep your folding carton costs lower. However, the price difference isn’t so drastic that you can’t opt for white kraft to enhance printing and artwork designs.

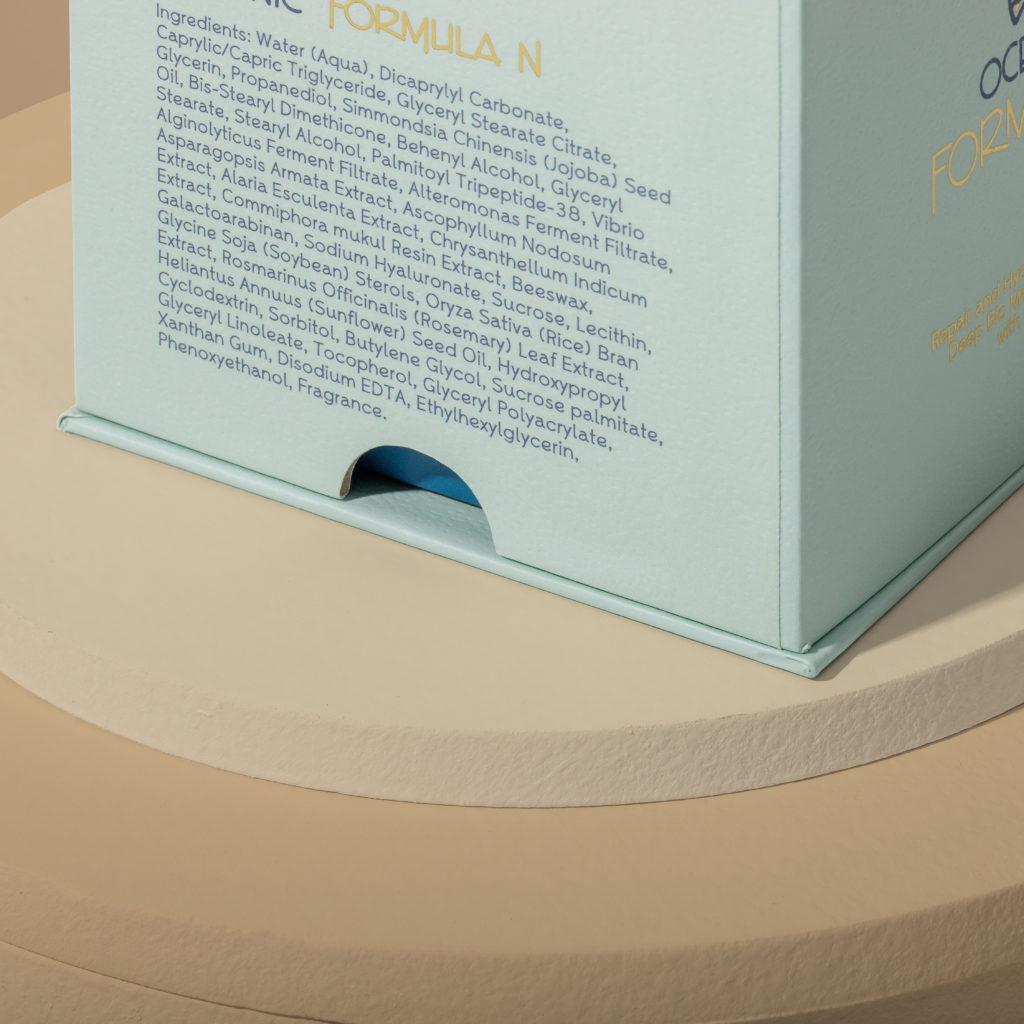

Rigid boxes

Rigid is for those looking to spend a little extra on their packaging.

If you’re looking for something high-end and sturdy, rigid boxes are the best option for you. It is also the priciest option on the market.

They are often used with luxury products to add a premium feel to packaging and an elevated customer experience.

To put it simply, rigid packaging consists of the highest quality, thick greyboard and it’s final construction is done by hand.

Rather than printing a simple dieline that allows you to fold your packaging accordingly, rigid packaging is constructed by glueing each edge and surface together by hand.

The construction of your packaging is the main reason for the premium price of this material. It also takes the longest to produce.

With luxury packaging come special finishes and coatings.

Matte Lamination

Matte lamination is the most recommended coating for luxury boxes. It emulates luxury for not much of your budget.

Specialty Coatings

If you simply have more than enough of your budget to invest in packaging design that requires more unique elements, you can also opt for special coatings.

These types of coatings are recommended for long-run orders due to its extra costs. However, if budget isn’t a problem, why not!

- Textured paper

- Embossed and Debossed

- Pearlized coating

- Glittered

- Reticulated

- Scented

- Foil Stamped

While rigid packaging is in fact the priciest packaging option, there are ways to reduce your costs for this type of material.

Opting for minimalistic artwork designs will help you refocus your budget to save on unnecessary costs for premium packaging.

Additional Packaging Materials

To avoid any hidden costs for your packaging, let’s also look into some additional packaging materials your products may need.

Some products may need extra support, especially during shipping, handling or stocking.

Of course this is also highly dependent on your product and distribution method.

Box Inserts

Box inserts are a cost effective way to add an extra layer of support and protection for your products.

Box inserts are available in;

- Carton (bleached and SBS white paperboard) – The cheapest option and less protective but still offers structure as well as printing and finishing capabilities. Kraft is slightly pricier than SBS paperboard.

- Corrugated – Cost effective and offers printing and finishing capabilities, if you are looking to print on the interior of your packaging.

- Blister – Plastic and non recyclable, it is molded to your products’ shape and size. However it is less cost effective to produce

- Foam – A pricier option on this list, foam inserts offer optimal cushioning to your products and are often used for luxury products.

- Molded Pulp – The most expensive option on this list, molded pulp inserts are molded to your products and are 100% recyclable. Molded pulp was once a cost effective box insert option. However, with the spike in eco-conscious shoppers, they have now become very expensive as they are made from raw material.

The Cost of Structural and Artwork Design Services

You may already have a design and structure ready for your packaging.

If this is the case this cost consideration may not be relevant to you.

However, if this is your first time creating custom packaging, you most likely will need artwork and structural design services to help you construct your packaging project.

It’s important to note that manufacturers will not help you source these services, it will be up to you to source them yourself.

This can lead to higher costs in the long run as you are paying a variety of different companies a premium to create your packaging.

Solution providers will be able to help with full project management including cost optimization as well as artwork and structural design services.

By paying a solution provider you will ultimately save on costs as you are not paying a premium to a variety of businesses, but just one.

This also makes your costs more straight forward and saves you a lot of time on your packaging project.

Artwork Design

The artwork design itself has an impact on your service costs for custom packaging as well.

Your artwork design needs to emulate and communicate your brand narrative while appealing to your target market. The more intricate your design ideas are, the more it will cost.

Packaging design is a very competitive market, therefore artwork design services can be quite costly.

However, this doesn’t mean you have to opt for minimalism for your packaging to be successful and cost effective.

Choosing cost effective materials with high quality printing and finishing capabilities will enhance your designs depending on the printing method you choose.

Working with a design service separately from a manufacturer means you are paying a premium for your artwork designs. Only some design services will offer structural engineering, but, this too will cost you quite a bit.

Once again, solution providers can help you save on your costs in terms of design services since you are working with one company on all aspects of your project.

Structural Engineering

It is beneficial to consult a structural engineer to make sure you are optimizing your product packaging accordingly.

While a standard shape may fit your packaging, the measurements still play a crucial role in both your products’ safety and your budget.

Keep in mind, measuring your packaging dimensions is dependent on the interior dimensions.

Making sure your product is measured correctly, ensures you are spending the minimum amount on materials and maximizing on your products’ protection.

Manufacturers will not advise you on measurements or structures. However, solution providers can offer structural design services and advise you on how best to optimize your packaging to protect and support your products.

If you are opting for more complex structural designs, structural engineers will be able to make your designs functional for the real world through structural optimization.

Working with a solution provider will allow you to save on structural engineering costs as you’ll be working with one company for all aspects of your packaging

All in all, structural design services are not as costly as you think, especially when working with solution providers.

Let’s delve into some popular packaging structures and how you can optimize your budget.

Corrugated

As previously discussed, corrugated packaging is one of the most popular packaging materials.

But what about structures?

The structure is ultimately up to you, but many opt for the following corrugated packaging structures, especially for e-commerce or subscription box businesses.

- Regular slotted corrugated packaging

- Full overlap corrugated packaging

- Open end corrugated packaging

Corrugated packaging on it’s own is already a cost effective option. The structure in this case will affect the price very minimally.

A great way to keep corrugated packaging costs low is opting for standardized structural designs, such as those mentioned above.

However, you can explore more corrugated structures.

Folding Carton

Your folding cartons structure options are nearly endless.

Because folding cartons are such a flexible packaging material, manufacturers can shape your packaging into basically any size and shape you want!

However, sticking to standardized structures can keep your packaging costs much lower, as it would be if you opted for kraft instead of white folding cartons!

Some popular structures include, but are not limited to;

Explore more folding carton structures.

Keeping folding cartons costs low entails opting for standardized structures that are easy to construct and manufacture.

Rigid

Rigid boxes, as mentioned previously are the priciest to manufacture because of the construction process and the quality of materials.

Because this packaging type tends to be the most expensive, your structures can be very complex and unique.

However, there are some standardized structures you can consider, even for rigid packaging.

These include;

If you’re looking to keep rigid packaging costs low, collapsible rigid boxes are your best bet.

Because they save an immense amount of space, you’ll be saving on your shipping and warehousing costs, while still maintaining the high quality feel of rigid packaging.

Rather than fitting your packaging on multiple pellets for shipping, you can fit them on 1 or 2 to optimize on your costs.

Comparing Printing Costs

One of the main reasons companies choose to opt for custom packaging, is the capability of printing your own branding straight onto your product packaging.

Your printing method is really up to preference.

There are a few popular printing methods used in the packaging industry.

There are three main options available for printing on custom packaging;

- Digital printing: Mostly used for smaller orders and is cost effective, designs are directly applied to the box.

- Offset printing: Uses a printing plate and rubber cylinder to transfer the design onto the packaging. It’s higher resolution and offers a sleeker finish, but is also on the pricier side.

- Flexographic printing: Designs are stamped onto the box directly (similar to digital printing) using a printing plate. This does tend to add up, as each plate can get costly. It only accommodates one color, so it’s best to use this for larger orders.

For the most part smaller-medium size businesses will opt for digital printing because it offers a good price for small quantity orders.

It’s also time efficient and offers endless design opportunities.

Digital printing does best for small simple designs. For complex designs, offset printing is recommended for its quality.

Offset printing can be quite costly, but the quality difference is drastic.

Offset printing allows for high quality printing of your artwork designs. While the price difference between digital and offset printing is quite drastic, you’ll be able to save if you choose to print high volume orders.

It is recommended to use offset printing for high quantity orders because the set up costs for printing will be much lower per unit.

While it may seem tempting to opt for digital printing to pinch a couple of pennies, it can reflect badly on your brand by lowering the quality of your packaging design.

In most cases it is recommended to opt for higher quality printing methods like offset printing to optimize on your packaging quality.

However, digital printing can still be successful for less intricate designs.

The Cost of Manufacturing

As mentioned a few times now, manufacturers and solution providers operate very differently.

So, it’s important to determine what services (mentioned above) you require to package your products.

Solution providers offer services for your entire packaging process, including manufacturing.

Price wise, you are paying a premium to one company to provide you the entire process from ideation to delivery.

Manufacturers on the other hand simply deal with your order. Everything up to and after manufacturing your order will be up to you.

Most importantly you will be responsible for making sure your manufacturer carries out quality control tests.

For example; for corrugated packaging it’s important to conduct the edge crush test to ensure your packaging is up to standard with your needs.

This also may mean you are bound to a smaller sea of manufacturers as geographic location becomes more of a concern.

Realistically, if you are sourcing a manufacturer yourself, you’d want them to be close by so shipping and logistics become easier to track and maintain.

Furthermore, you’ll want to be able to get your hands on a sample or prototype before giving manufacturers the green light for production.

While it may seem more cost effective to simply settle for a manufacturer and to hand pick the other services you require.

Over all you’ll be paying much more than simply paying one premium for all your services.

Not to mention, managing your packaging project becomes much easier as all your processes are packaged in one space.

Read more about choosing the right custom packaging company for your project.

The Cost of Shipping and Logistics

When considering how much custom boxes cost, shipping and logistics need to be a key consideration in your budget.

Your packaging structural design is somewhat dependent on your shipping method, as the weight and dimensions play a large role in your shipping costs.

Once you have some rough figures, you can then estimate how much it costs to ship packaging through different transport modes.

Furthermore, keep in mind that you may need to outsource services to ensure your logistics are planned out accordingly with your product launch.

Especially if you choose to go with manufacturers instead of full project cycle providers, your logistics are up to you to figure out.

This could potentially mean higher final costs.

Air Shipping

Air freight tends to be a common choice for international deliveries since it’s the most time efficient.

Air carriers generally charge based on the item’s weight and the amount or volume of shipped items.

The weight is calculated by the weight of the item itself or the item’s dimensional weight (i.e., the packaging and item combined), whichever is heavier.

Keep in mind that Air Shipping may not be necessary depending on where your manufacturer is located.

You may want to opt for one of the other shipping methods mentioned below to ensure your packaging doesn’t break the bank.

Water Shipping

Water shipping is an alternative for heavy shipments (over 500 kg) as it’s more cost-effective than air freight.

Charges are based on the volume of goods, as opposed to weight.

However, keep in mind that this might not be the most time efficient shipping method.

So, if you’re in a time crunch for your product launch, although cost effective, may not be the best way to optimize your custom packaging Logistics.

Ground Shipping

Ground shipping tends to be the most popular delivery method of choice, but it comes with challenges.

The dimensional weight of the item is an important part of determining the shipping price.

If you’re trying to work out how much it costs to ship packaging, you will need to think about your custom boxes’ weight and design and how that fits with ground shipping rates.

Ground shipping is very dependent on the dimensions of your packaging as the shipments may need to be split up.

Think of it this way; if you’ve got 500 oddly shaped boxes that do not have much capability of being stacked, you may need more than one shipping van/truck to have your packaging shipped to you.

This also plays into your costs for custom packaging as you may be paying more for ground shipment than you anticipated.

Keep in mind; ground shipping is only an option if the manufacturer is fairly close to you, otherwise you may need to opt for Air or Water Shipping instead.

To estimate how much it costs to design packaging and how much custom boxes cost in general, your shipping and logistics play a large role in raising your end costs.

While you may think you’re getting a steal with your custom designs and packaging, your logistics may change your mind very quickly.

That’s why it’s important to consider your shipping and logistics before you enter your manufacturing process.

Once you have a vision in mind, you’ll be able to better estimate how much it costs to ship packaging.

It’s essential to think about custom packaging weight when estimating costs and the volume of custom packaging being created to choose the right type of box and printing for your budget.

If you aren’t sure about how much it costs to design packaging and how much it costs to ship packaging, you can request a quote to get an exact estimate for your packaging needs.