Table of Contents

Sushi has become a beloved dish for many people in the world. While the dine-in experience is amazing, that doesn’t mean take-out lacks that experience. With Torch Sushi, quality cuisine can take place anywhere, even in your home.

Torch Sushi brings modern, innovative flavors to the traditional method of Oshizuki (押し寿司), meaning “pressed or boxed sushi”. They offer take-out pressed rolls such as Aburi sushi (flame-seared sushi) as well as maki rolls, bento boxes, and more. All their sushi is made with premium ingredients and original recipes.

In order to deliver their sushi to customers, they were looking for food packaging durable enough to store the food while presenting it with an air of sophistication.

The Challenge

Torch Sushi has worked with PakFactory in the past and was interested in working with us again. Before they reached out to us, Torch previously used standard take-out boxes and needed a new method that can get their brand out there. They wanted to use a packaging structure that looks presentable while having a tough exterior. The challenge here was to be able to create a structure that can carry the weight of the food and prevent it from damage during travel.

The Solution

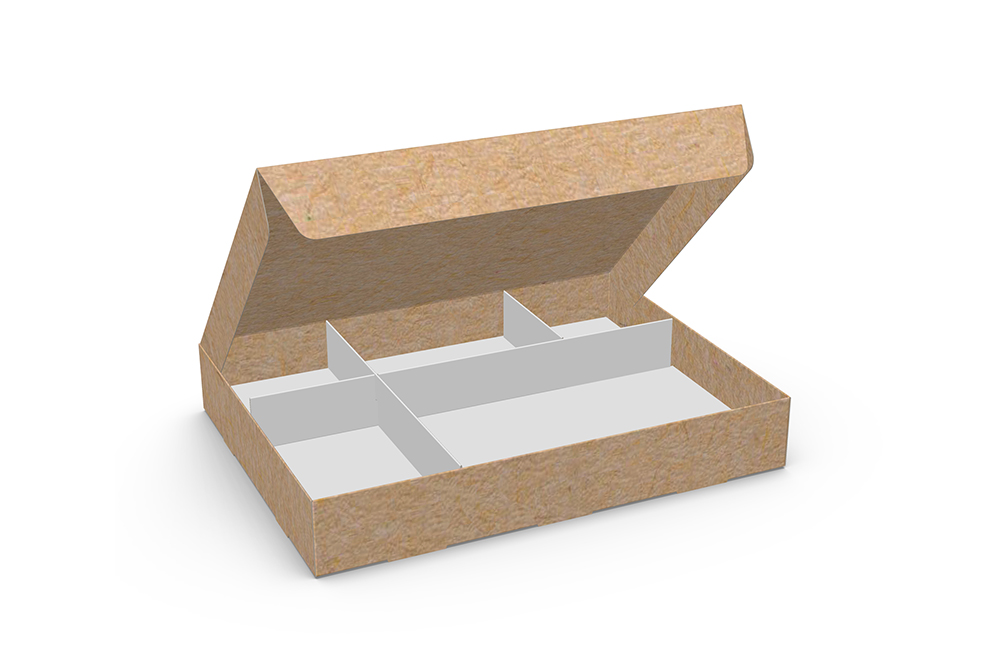

In order to explain the final product that Torch Sushi is using now, we need to explain what led to the final product. Similar to past projects, Torch wanted to revamp their take-out packaging. At the beginning of this process, they kindly provided a sketch of a packaging idea they had in mind. This involved a packaging box with custom inserts that fit their different types of sushi.

The element to remember when working with food is that food packaging must always have a food-grade protective lining. This lining needs to be anywhere where the food may come in contact with the packaging material and inks. Having a food-grade coating prevents your food from potential contamination, so it’s good to know about this necessity. We kept this in mind during production.

Packaging Batch 1

The first batch of packaging we produced for them was a kraft box with custom inserts. Torch Sushi loved the appearance of the kraft as it gave off that natural and authentic feel to their products. However, the kraft was unfortunately flimsy. This can happen if the thickness of the material cannot support the weight of the product. While the structure itself was built securely, the thickness of the kraft causes the packaging to slightly curve under the sushi’s weight. Even though the material did not hinder the overall performance, both parties wanted to raise our standards.

For the next batch, we worked together to improve the material and secure the product’s weight.

Packaging Batch 2

After looking at and testing a number of materials, we had a solution. This batch of custom packaging shifted from kraft to paperboard folding carton. Torch Sushi wanted to have these boxes pre-folded, however, that approach would have been costly for them and time-consuming. We explained that having the manufacturer assemble pre-folded packaging boxes would increase their production costs as well as increase shipping costs. It increases the shipping costs because pre-folded boxes will take up a lot of cargo space compared to flat, foldable packaging. Torch understood this and together we found a way to reduce costs and save time.

We suggested a 6-corner box, which is typically used for cakes, donuts, and other take-out food. This was an optimal choice because this structure is compatible with paperboard and it can be shipped flat, a happy medium for Torch’s request. They approved of this design and the custom box was produced with an AQ semi-gloss finish.

Final Packaging Batch

Torch Sushi came back to us, saying they enjoyed our past packaging batches but wanted to revamp their current packaging’s coating. This was an easy fix because they didn’t want to change the design, just the finishing. Instead of an AQ (aqueous) semi-gloss, they wanted a matte finishing, and we were easily able to do that for them.

Throughout the whole packaging process, the artwork design and the inserts have always been the same. We were able to satisfy their artwork needs and their inserts and box dimensions were measured accurately. The only trial and error we faced was the packaging material. Fortunately, Torch had a flexible timeline that allowed both of us to experiment and research to find the product the best-suits them.

The Result

Torch Sushi was content with their past packaging and are excited for when their new and improved packaging arrives. Their past take-out boxes were well-loved amongst their customers, hopefully this time is no different!

If you are looking to get custom packaging like Torch Sushi, contact our product specialists to get started!