Toggle Nav

Toggle Nav

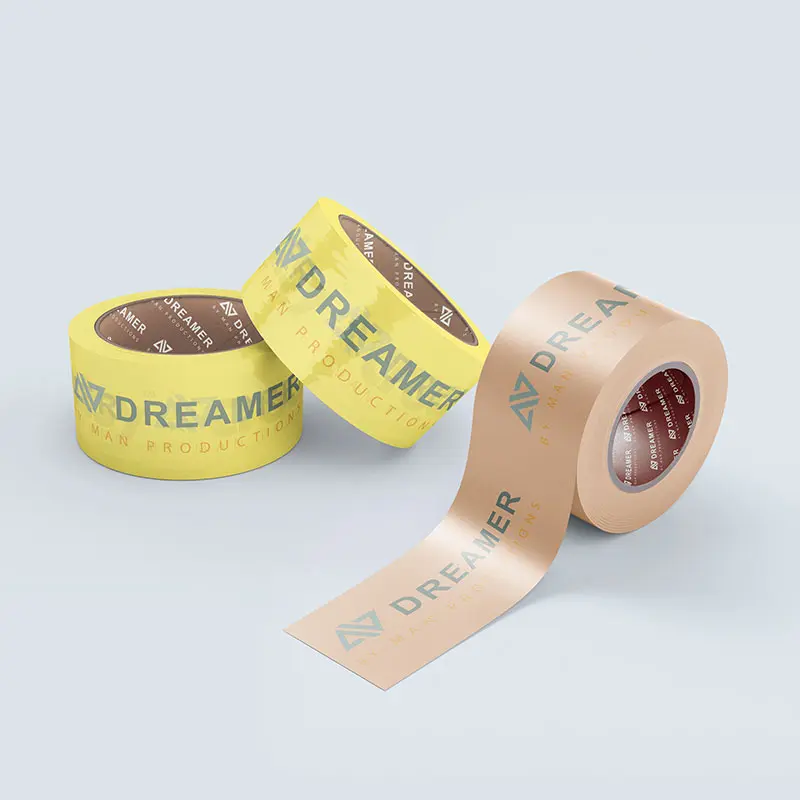

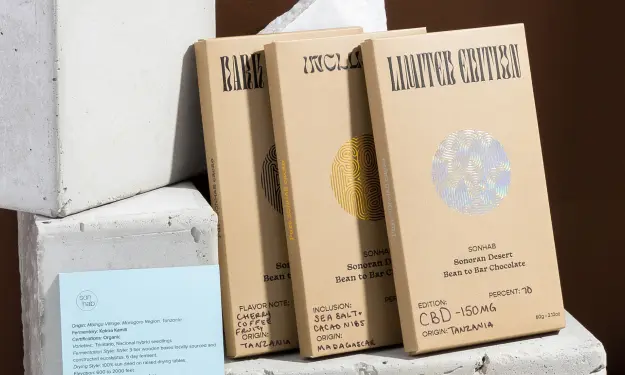

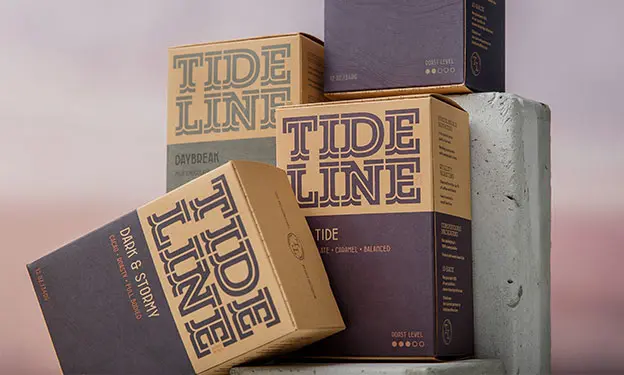

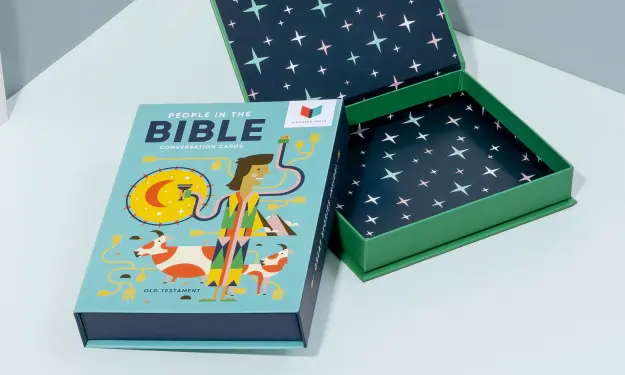

Create custom boxes & packaging of your dreams

Order personalized, high-quality custom printed packaging and branded boxes your customers will love all-in-one place.

We are your best solution for Custom Packaging

Never worry about going to multiple sources to get your dream packaging.

Dedicated expert support

Make more informed decisions with unlimited support from our team of product specialists.

End-to-end solution

From concept to your door, we simplify your project by handling everything for you.

Custom sizing

Fully control the size of your packaging with no limitations to tailor to your product.

The PakFactory Promise

We guarantee the highest quality product and customer experience with every order!

Extensive option library

Access over 50+ options that you can utilize to create your very own unique box experience.

Professional design services

Achieve agency-level packaging designs from our professional artwork and structural designers.

Managed manufacturing

Get the best manufacturing with stringent processes as well as transparency on your production.

Hassle-free logistics

Have us manage your logistics to get the best prices and turnaround time for shipping.

Sustainability

Easily become a more sustainable brand with our range of eco-friendly products and options.

Meticulous proofing

All orders go through our meticulous proofing system before going into production.

Proactive cost optimization

Get proactive cost optimization on every project to ensure you are spending less for packaging.

Multi-packaging capabilities

Skip looking for multiple vendors and easily package your entire product line all-in-one place.

One for all solution, for custom printed packaging

Get everything custom packaging your business needs all in one place.

Looking for something else? We can help.

Shop packaging solutions by industry needs

Find the perfect packaging solutions tailored to your industry niche.

Let’s create a sustainable future together

Grow your business with eco-friendly alternatives to packaging.

Services that meet your packaging needs

Our 360 PakFactory approach delivers all the services you need to create the best packaging solutions

your products and business needs in order to acheive total packaging success.

Packaging audit

Identify and analyze your current packaging and spot areas of improvement for your packaging.

Packaging strategy

Collaborate and develop a tailored packaging strategy with our specialists to meet your needs and goals.

Cost optimization

Save more on your custom packaging with cost optimized strategies like material alternatives, reduction and supply chain optimization.

Supply chain optimization

Analyze and improve your existing supply chain for the most efficient procurement network.

Packaging artwork design

Work with packaging designers to create stunning artwork designs made to complement your branding.

Packaging engineering & design

Tailor packaging structures and designs to your product needs and journey with the help of dedicated engineers.

Sampling & prototyping

Test and tweak your packaging and artwork designs with samples to bring your vision to life before production.

Packaging testing

Conduct critical tests like drop and crush tests to ensure your packaging holds up to certain environments.

Material optimization

Minimize material usage to reduce unnecessary packaging waste and material costs with our structural engineers.

Strategic sourcing

Get your packaging strategically sourced to reduce your overall shipping costs and lower your carbon footprint.

Managed manufacturing

Manufacture your packaging at managed facilities for top quality assurance and reliable results no matter where you are.

Multi-packaging ordering

Build an entire product line in one place using a range of certified facilities worldwide for every piece of your packaging.

Quality control management

Have confidence in your packaging materials through managed stringent quality control and monitoring.

Route optimization

Ensure on-time deliveries with reduced carbon emissions through working with our dedicated logistics team.

Cargo optimization

Keep costs low with optimized solutions designed to save space on cargos and ensure on time deliveries.

Just-in-time delivery

Work with a dedicated product specialist to ensure all componets of your packaging are ready for your launch date.

End-to-end delivery

Let us handle every step of your shipping your packaging order to ensure safe and on-time deliveries.

Customer satisfaction

Build a loyal customer base and make a good first impression with solutions optimized to your target market.

Project evaluation

Evaluate your packaging process with a packaging expert to develop strategies for smoother operations.

Project optimization

Optimize your packaging for smoother supply chain operations and an improved return on investment.

Total packaging success

with 360° PakFactory approach

Save cost & time

Benefit from expertly engineered solutions designed to save you as much time and money as possible.

More reliability

Get your packaging from certified manufacturers for reliable results every single time.

More brand impact

Leave your customers with a lasting impression with solutions designed for brand impact and recognition.

Become sustainable

Choose from a large range of eco-packaging options that are certified and sustainably sourced.

Your ultimate packaging manufacturer

PakFactory is your go-to destination for everything custom boxes and custom packaging — by delivering support at every step of the custom packaging journey from concept to reality, our customers are able to achieve the packaging of their dreams with ease.

Global Supply Chain

Get access to any custom packaging, boxes and additional materials using our global packaging supply chain.

50+ Certified Facilities

Benefit from certified custom packaging sourced from over 50 certified facilities world wide.

Manufacturing Excellence

Add a higher perceived value to your products with reliable custom packaging engineered to deliver quality assurance.

See what our customers say

Don’t let what we say influence you, take it from our customers!

I used Pakfactory for my jewelry boxes and they turned out lovely! The turnaround was much slower than expected and would have hoped.

Really great experience working with Ken Lo and PakFactory. I spoke to many vendors prior to choosing PakFactory and I'm so grateful I went with them.

I've worked with PakFactory on the production of several boxes for my soap company. The boxes always turn out better than I could imagine. The quality is excellent and the printing is always spot-on.

The value that PakFactory has added to our brand is immeasurable. By making such high quality packaging, we are able to provide our customers with a top shelf experience.

PakFactory was superb from start to finish. Our artwork was done exactly as presented and in the highest quality. Really fast shipping too. I highly recommend PakFactory!!!

Thanks to PakFactory’s proactive optimization on our existing packaging, we were able to save costs on material as well as optimize size for saving space on shipping for even lower shipping costs!

With the help of PakFactory running my entire packaging supply chain and helping me managze decisions, I was able save time and hassle to focus on my customers.

PakFactory’s team has been extremely communicative to ensure that my packaging is perfect by going through rigorous testing and quality control. The team is extremely reliable also!

We decided to re-brand utilizing PakFactory’s designer and we don’t regret it! We’ve seen positive feedback from our customers and resulted in an increase to our sales!

Fantastic to work with at PakFactory. They answered all of my questions promptly and worked with me to get the exact right design for our product. This included many emails back and forth.

I’ve purchased custom printed boxes from them twice now. They’re really high quality, with bright colors and perfect printing. The whole process was super easy too, from start to finish.

Frequently asked questions

What is your minimum order quantities (MOQ)?

Our minimum order quantity (MOQ) depends on the specific product line and customization requirements. Please reach out to our product specialists for detailed information regarding the MOQ for the product you are interested in. Alternatively you may check our list of MOQs here.

We strive to accommodate orders of various sizes to meet our customers diverse needs so don’t hesitate to contact us!

Can you produce less than your minimum order quantities (MOQ)?

We strongly recommend that our esteemed customers adhere to our minimum order quantities to mitigate associated setup costs. However, we do accommodate smaller orders upon request and strive to fulfill our customers' specific needs.

If you are interested in placing an order for a sample, we kindly request that you reach out to our dedicated product specialists. They will be delighted to assist you in this regard and provide further guidance.

How long is your production time?

Our current production times typically range from an estimated average of 10 to 30 business days, contingent upon factors such as packaging type, order size, and the time of the year. It's important to note that greater customization and the inclusion of additional processes in your custom packaging generally result in slightly longer production durations.

Please be aware that all dates provided are estimates and not guaranteed. Production times are subject to change without prior notice due to the dynamic nature and unpredictability of order volumes. View our per product line turnaround times here.

Are all your products recyclable?

Absolutely! We take pride in ensuring that all our paper-based packaging solutions are entirely recyclable. If you are seeking more sustainable alternatives for your packaging needs, we encourage you to consult with our knowledgeable product specialists. They will provide expert guidance and assistance in exploring environmentally friendly options that align with your requirements.

Will I receive a proof before my custom packaging goes to production?

Prior to proceeding with production, our proficient pre-press team will provide you with a digital proof of your custom packaging. This comprehensive proof allows you to review and evaluate the final design and make any necessary adjustments or approvals before moving forward with the production phase.